Carbon neutrality grabs the front page every day—electric cars, wind farms, solar panels. But a quieter shift is changing the heart of heavy industry. Sulfuric acid production, often called the mother of industries, feeds chemicals, fertilizers, and metals. Plants now face tight rules on emissions and energy use. They need reliable heat for start-up and for drying sulfur dioxide, but fuel prices swing and regulators watch every stack. This pressure pushes leading facilities to look again at a familiar tool made new: the high-efficiency electric gas heater. These units turn electricity into process air heat with almost no waste, protect costly catalysts, and cut risks in explosive areas. Top plants choose them not for headlines, but for real gains in the control room and on the balance sheet.

Economic Reality: Smart ROI Beyond the Electricity Bill

While electricity carries a higher unit price than fossil fuels, the equation changes when you factor in efficiency and usage patterns. Sulfuric acid plants typically operate heaters intermittently—primarily for converter start-ups or managing moisture spikes. In these critical windows, efficiency is king. Unlike fuel burners that waste heat through exhaust stacks, electric heaters transfer nearly 100% of the input energy directly to the process gas. In fact, a well-designed electric gas heater delivers a lower total ownership cost over a decade. The table below compares a 380 V, 480 kW unit against a traditional gas-fired burner for a typical 1,000 t/d acid plant start-up cycle (8 hours, 60 starts per year).

Lower Upfront Cost and Simpler Operation

For acid plants, gas heaters are mostly used for start-up, which means intermittent operation rather than round-the-clock running. Therefore, electric gas heaters naturally reduce Capital Expenses (CAPEX) by eliminating the need for complex burners, fuel storage, and piping—often cutting costs by 20-30%. Maintenance drops too, with fewer parts to check or replace. Unlike combustion systems that require safety checks for fuel leaks, electric models are “plug-and-play.” It skips the hassle of fuel storage and piping, simplifying installation in tight spaces.

Shifting from costs to energy capture, it’s clear why efficiency plays a big role in the long run. Plants that use electric gas heaters report better control over their budgets, especially when fuel prices swing wildly.

Capture Every Unit of Energy: >95% Thermal Efficiency

Electric gas heaters boast thermal efficiency above 95%, sometimes hitting near 100%, far outpacing combustion heaters that lose 20-30% of energy through exhaust stacks. In industrial air heater applications for sulphuric acid production, this means almost all input power turns into useful heat for drying sulfur dioxide or warming process gases. No fumes escape to the atmosphere, unlike fuel burners that waste heat skyward. Real-world data from lithium-related acid roasting shows electric systems recover energy that gas setups simply vent away. For a 500 kW unit running intermittently, this translates to savings of 15-25% on energy bills over a year. Plants focused on equipment for drying sulfur dioxide find this efficiency crucial, as it keeps operations lean without skimping on performance.

With efficiency locked in, the next layer involves shielding against market ups and downs. Electric gas heaters provide a buffer that combustion models can’t match, especially in volatile times.

Future-Proofing Against Fuel Volatility

Fuel prices can jump 50% in a bad year, hitting combustion-based industrial heating equipment hard. Electric gas heaters sidestep this by tying costs to electricity grids, which often stabilize through long-term contracts. In sulphuric acid production, where gas heaters fire up sporadically, this predictability adds up—some plants report hedging against $100,000 in annual fuel spikes. In addition, as renewables grow, electricity rates could drop further. Equipment for drying sulfur dioxide benefits here, with electric models adapting to green power without retrofits. This forward-thinking approach keeps top plants competitive, avoiding the pitfalls of oil or gas dependency.

Process Precision: Protect Your Catalyst Investment

Beyond dollars, the heart of sulphuric acid production lies in the converter, where catalysts turn SO2 into SO3. Here, electric gas heaters stand out as precise industrial heating equipment, safeguarding expensive vanadium beds from damage.

- Temperature Sensitivity:Vanadium catalysts in sulphuric acid production need exact activation temperatures, typically between 400℃ and 420℃, to kick off the reaction without degrading. Stray too low, and conversion stalls; go high, and thermal shock shortens life. In setups using industrial air heaters for drying sulfur dioxide, even small fluctuations can cost thousands in downtime. Studies show catalysts last 5-7 years under ideal conditions, but poor heating cuts that in half.

- The Electric Advantage: Unlike combustion heaters prone to flame ups and downs, electric gas heaters use PID controls for accuracy within ±1℃. This makes them ideal industrial heating equipment for sulphuric acid production, where steady heat ensures smooth gas flows. For equipment drying sulfur dioxide, this control prevents hot spots that could warp pipes or unevenly heat air.

- Quantifiable Returns: By avoiding catalyst thermal shock, electric gas heaters extend bed life by 20-30%, saving $200,000 or more per replacement cycle in large sulphuric acid production facilities. They also ease the shift to autothermal stages, where the reaction sustains itself. In industrial air heater roles for drying sulfur dioxide, this means fewer interruptions and higher yields—up to 99.5% conversion rates in optimized plants.

Unlock the Value of Clean and Safe Operation

Clean operations aren’t optional anymore; they’re a must for sulphuric acid production. Electric gas heaters deliver on this front, cutting emissions and risks that plague older systems.

Achieve Emission-Free Heating at the Point of Use

Electric gas heaters produce no exhaust at the source, unlike combustion units that release CO2 and NOx. In the context of sulphuric acid production, this capability is crucial for complying with strict environmental mandates—helping some plants reduce their carbon footprint by 90%. For industrial heating equipment used in drying sulfur dioxide, this “clean heat” ensures that no combustion byproducts contaminate the process gas

Intrinsic Safety in Hazardous Environments

Gas systems carry leak and explosion risks from pipelines and open flames. Electric gas heaters wipe these out, with no fuel lines or ignition sources. In sulphuric acid production plants, where corrosive gases abound, this reduces incidents—industry reports show 40% fewer safety events. Industrial air heaters like these fit seamlessly, offering peace of mind without extra guards.

NHD Gas Heater: Engineering for Acid Plants

When it comes to reliable solutions in industrial heating equipment, NHD’s EH96 series electric gas heaters stand out as tailored for the unique challenges of sulphuric acid production. These side-door and top-door gas heaters are engineered for heating air, dry SO2 gas, and fuel flue gas during the converting process, boasting over 95% heating element exposure for superior heat transfer and efficiency.

Side-Door vs. Top-Door Designs

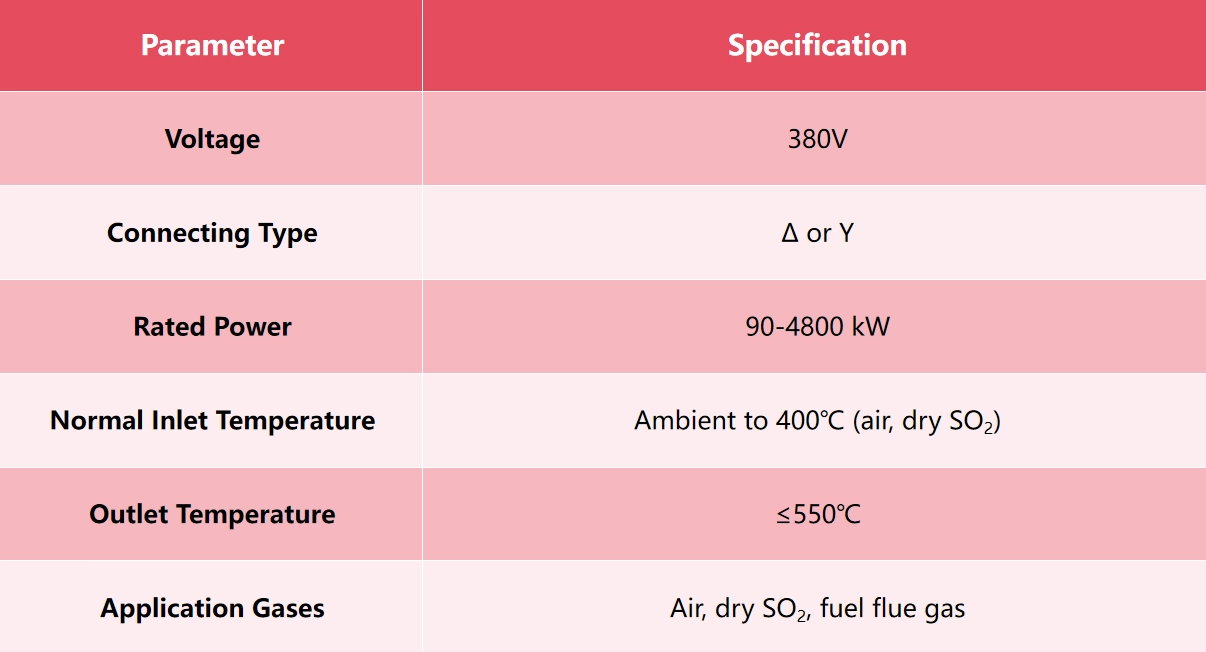

Heating elements in gas heaters wear out over time, needing swaps without halting production. NHD’s side-door gas heater suits plants with tight overhead space or no crane access, allowing horizontal pulls for quick fixes—often in under an hour. The top-door gas heater works best in compact areas with vertical lift options, simplifying upward removals. Both handle powers from 90 to 4800 kW, with inlet temperatures up to 400℃ and outlets to 550℃, perfect for drying sulfur dioxide or heating air in sulfuric acid production.

Here’s a main performance table for quick reference:

These designs make NHD’s electric gas heaters versatile industrial air heaters, blending form and function for real-world use. Building on robust builds, NHD focuses on tech that boosts life and speed.

Maximum Heat Transfer with “Pipeline-Equivalent” Resistance

Efficiency in acid plants isn’t just about heat; it’s about airflow. NHD heaters feature a proprietary winding method that exposes over 95% of the heating element surface directly to the gas flow.

- Fast & Direct Heating: This design eliminates shielding and mutual interference, allowing for rapid temperature ramp-ups (“Fast Heating”).

- Low Pressure Drop: Crucially, the internal structure is engineered so that air resistance is basically equivalent to that of the pipeline itself. This ensures your main blower performance is never compromised, whether handling air, dry SO₂, or fuel flue gas.

Intrinsic Safety & Extended Element Life

Reliability is the cornerstone of our design. By maximizing the surface area, we maintain a low surface power load, making the resistance wires significantly less likely to break compared to standard coils.

- Safety Details: We address common failure points by adding a terminal transition bar to isolate heat and prevent cable insulation burnout. Additionally, high-temperature packing seals guarantee zero leakage, creating a safe environment for operators.

- Process Redundancy: Even if one group of elements is taken offline, our design ensures the spatial temperature distribution remains uniform, protecting your catalyst bed from thermal shock.

Lightweight Design for Rapid Maintenance

We understand that downtime is expensive. NHD heaters utilize a lightweight internal insulation structure and a corrosion-resistant stainless steel liner.

- Easy Retrofit: The entire unit weighs only 1/3 of traditional grid-type furnaces of the same power, drastically reducing structural load requirements.

- Quick Access: The signature Quick-Opening Door Structure allows maintenance teams to access internal components rapidly, making element replacement fast and labor-saving.

Schlussfolgerung

For top-tier sulfuric acid plants, investing in high-efficiency electric gas heaters is a strategic decision crucial for process excellence, operational safety, environmental compliance, and long-term cost competitiveness. These devices, as industrial heating equipment, transform intermittent tasks like drying sulfur dioxide into efficient, low-impact operations. Leveraging its deep understanding of sulfuric acid processes and engineering expertise, NHD provides heating solutions that not only meet but exceed these expectations, helping leading companies confidently move towards a sustainable future. Contact us today at [email protected] to discuss how our electric gas heaters can fit your plant—it’s a step toward smarter, greener production.