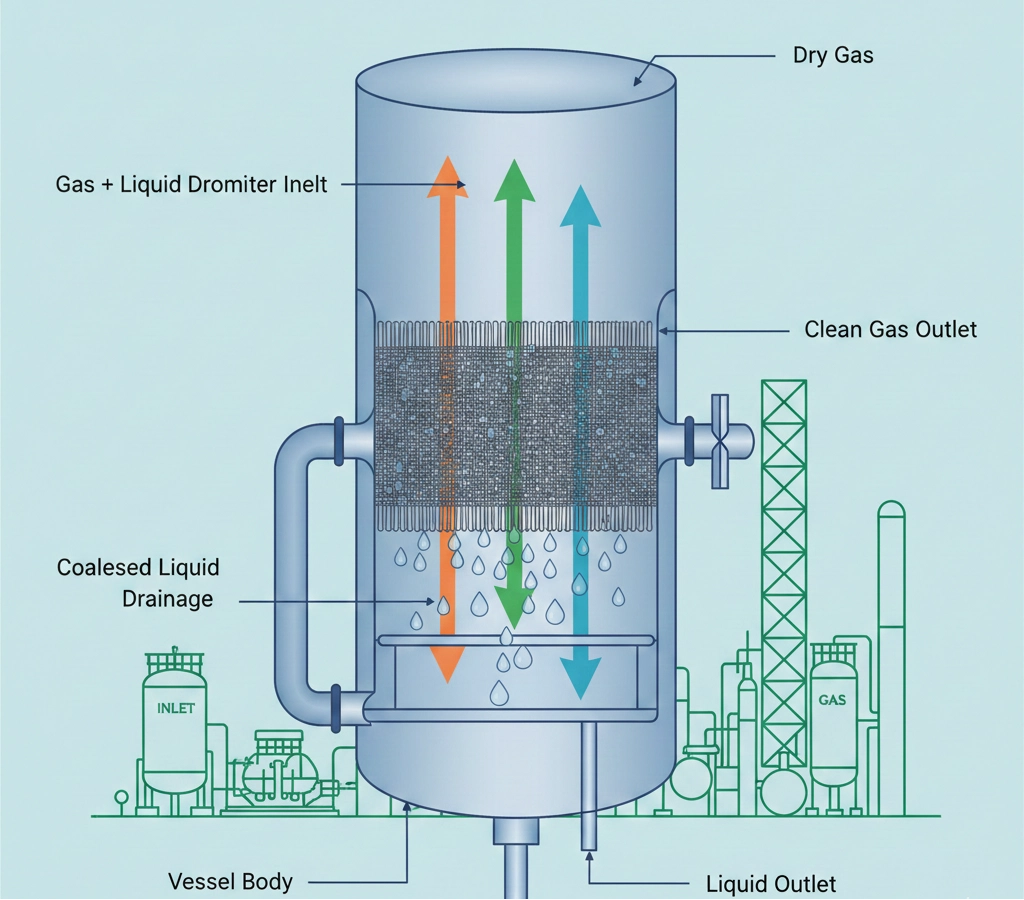

When we cook porridge in the kitchen, we often see steam condensing into water droplets on the boiling pot lid and then falling back to the bottom of the pot. A similar phenomenon occurs in large industrial towers—but these tiny droplets are not water, but rather corrosive acids or harmful pollutants. Efficient gas-liquid separation is the backbone of process stability in industrial towers. Without effective filtration, tiny corrosive droplets do not just vanish—they cause severe operational headaches. This is precisely the core mission of metal mesh demisters, also known as wire mesh demister pads. They play a key role in gas liquid separation, capturing mist from gas streams to keep processes running smoothly.

Without proper demister pads, acid mist can carry over, leading to equipment corrosion that shortens machinery life by up to 30%. Energy use spikes as systems work harder to handle the extra load, sometimes increasing costs by 15-20%. Meanwhile, maintenance downtime for cleaning or repairs can halt operations for days, costing companies $10,000 or more in lost production. As a designated manufacturer approved by the Chinese Ministry of Chemical Industry, NHD deeply understands these pain points. We have developed three generations of wire mesh demister pads (also known as mist eliminators), evolving from standard designs to patented maintenance breakthroughs.

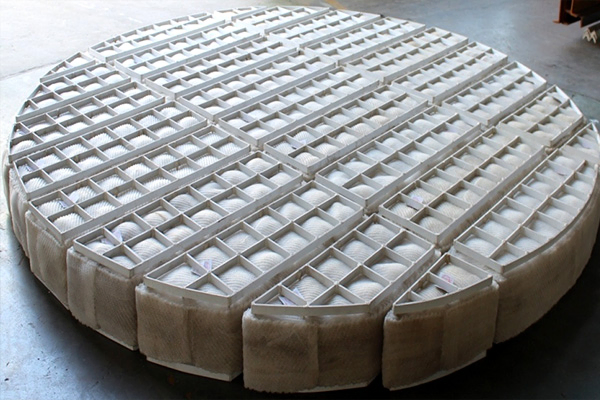

1st Generation: Standard Mesh — For Simpler Loads

The first generation of wire mesh demisters from NHD set the foundation for effective gas liquid separation in many settings. These standard wire demisters are straightforward designs that focus on basic needs. They work by trapping droplets on a mesh of fine wires, letting clean gas pass through.

This early model paved the way for broader use in industries where mist removal is essential but conditions stay mild. Yet, as operations grew more demanding, users noticed gaps in how these demisters held up over time. Maintenance often meant stopping everything, which sparked ideas for better versions. Let’s look closer at what made the standard type shine and where it fell short.

Core Advantages: Lightweight & Low Pressure Loss

Standard wire demisters stand out for their small size and light build. Weighing just a fraction of bulkier alternatives, they fit easily into towers without adding much strain. Pressure also drops and stays low, which means pumps and fans don’t have to push as hard. This saves energy right from the start.

In practice, these demister pads capture up to 98% of droplets larger than 5 microns. The wire mesh demister pad uses layered wires to create a tortuous path for gas, forcing mist to stick while gas flows free. NHD offers multiple material options based on customer requirements and actual working conditions, including SS304, SS316L, PP, PTFE, Alloy 20#, and F4H (PTFE-coated wire) to ensure reliability under different chemical environments.

Application Scenarios & Initial Limitations

These standard wire demisters perform reliably across multiple stages of the sulfuric acid production process, especially where stable gas flow and moderate mist loads are present.

For example, in drying towers, they remove acid mist to protect downstream equipment and keep the gas stream dry before entering the converter. In absorption towers, they capture fine sulfuric acid aerosols to maintain product purity and reduce stack emissions.

But challenges arise in high-volume or variable settings. Cleaning requires entering the tower, risking worker safety and extending downtime to 8-12 hours. They lack flexibility for changing loads—if flow drops, efficiency dips without adjustments. This led NHD to innovate, drawing on feedback from users facing these hurdles. The push for easier upkeep and better adaptability set the stage for the next step in wire mesh demister technology.

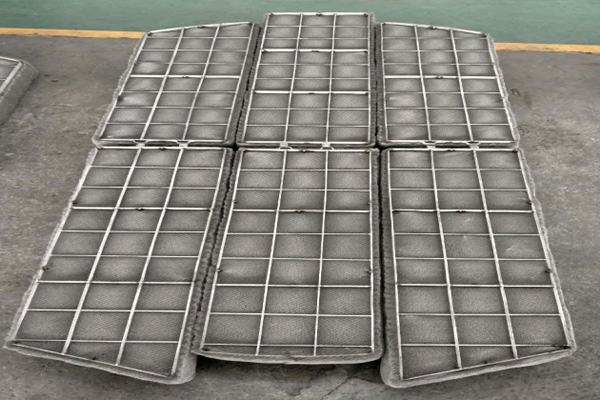

2nd Generation: Drawer Mesh — No Entry, No Shutdown

Building on lessons from the standard type, NHD’s second generation brought a fresh approach to demister pads. The drawer type wire demister allows quick access without halting operations fully. As a patent holder (Patent No. ZL93.2.46402.5), NHD designed this to tackle maintenance woes head-on. This is NHD’s very first patent and the starting point of decades of continuous advancement in demister technology. It fits like a sliding drawer in the tower, making swaps simple. This upgrade suits plants where uptime is critical, like continuous chemical processing. It addresses the rigidity of earlier models by adding smart features for real-world use. Now, let’s explore the key leaps that make this generation a game-changer for gas liquid separation.

No Tower Entry Required: A Leap in Maintenance Efficiency

The biggest win with drawer-type wire demisters is pulling them out without climbing inside the tower. Workers stay safe outside, avoiding confined spaces and hazardous fumes. A simple mechanism lets you slide the unit free in minutes, compared to hours for standards.

NHD, as the demister manufacturer behind this patented design, ensures sturdy builds that seal tightly when in place. This means no leaks during runs. In sulfuric acid plants, this cuts injury risks by 40%, based on user reports. In addition, it speeds up inspections, letting teams spot issues early without full teardowns.

Longevity, Stability and Load Adaptability

Easy cleaning extends life of these wire mesh demister pads. Rinse them off-site without harsh tools, preserving the mesh for years—up to 5-7 in tough conditions. The simple structure uses fewer parts, so breakdowns are rare, boosting overall stability.

A standout feature is the blind plate option. It lets you block sections for low-load runs, maintaining efficiency even when flow halves. This adaptability shines in variable processes like seasonal refining, where demands fluctuate. NHD’s design handles loads from 50% to 100% without drops in performance, saving on energy and reducing wear. Short repair times, making it a practical choice for busy operations.

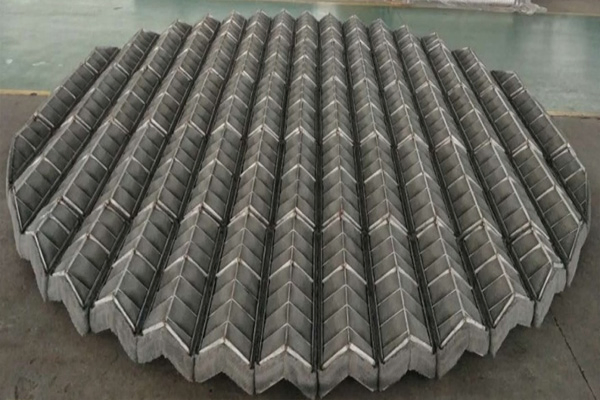

3rd Generation: V-Type Mesh — Peak Efficiency & Anti-Re-entrainment

Building on the full strengths of the first and second generations, NHD pushed boundaries further with the third generation, introducing the V-type wire demister. This patented (Patent No. ZL97.2.36744.6) demister refines gas liquid separation by tackling stubborn issues like droplet re-entry. Its angled shape channels flow better, capturing more mist with less effort. Ideal for high-stakes environments, such as nonferrous metal processing, it outperforms predecessors in tough spots. Users see gains in throughput and purity, addressing pains from earlier technology.

Solving the Re-entrainment Challenge

Re-entrainment happens when captured droplets get swept back into the gas stream by fast flows, slashing separation rates. In standard setups, this can cut efficiency by 10-20%, leading to more pollution or product loss.

The V-type wire demister counters this with a sloped design that guides droplets down and away. Gravity pulls them to collection points, preventing blowback. Tests show it boosts capture to over 99.5% in high-velocity gases. NHD’s version, built with precision weaving, ensures even distribution, minimizing weak spots.

Larger Area Higher Performance

By folding the mesh into a V, this demister increases the filtering area by 15% over flat types. More surface means better contact with mist, handling denser loads without clogging. It matches the output of two stacked standard demisters but in one unit—saving space and weight. In applications like acid towers, this translates to 20% higher throughput. NHD uses quality wires for durability, standing up to corrosive mists without quick degradation.

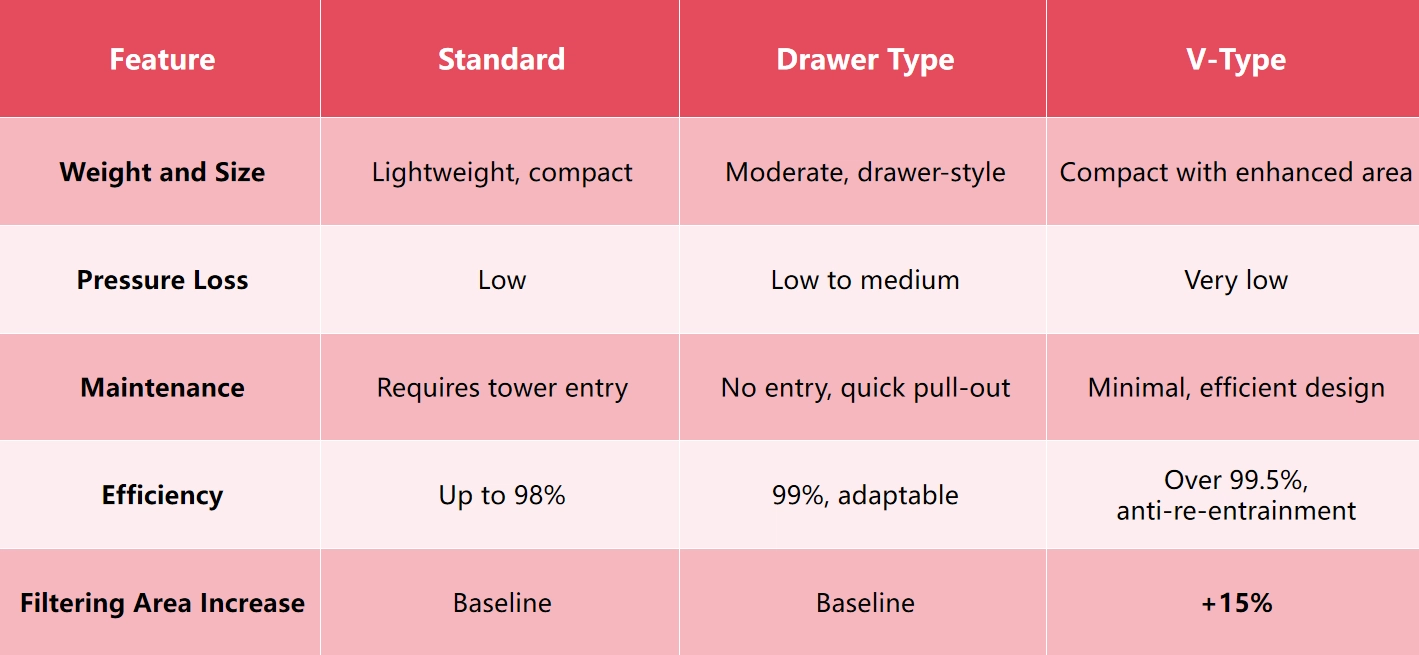

A Comparative Overview of All 3 Generations

To see how far wire mesh demister technology has come, compare the generations side by side. Each builds on the last, solving specific hurdles in gas liquid separation.

NHD Helps You Choose the Right Optimal Demister

Finding the best wire mesh demister pad starts with your setup. NHD offers guidance based on flow rates, mist types, and tower specs. From off-the-shelf standards to tailored V types, we cover it all.

Our team assesses needs like corrosion resistance or high temperatures, suggesting materials such as 316L stainless or specialized alloys. The custom sizes ensure perfect fits, boosting gas liquid separation. As a designated demister manufacturer for major industries, NHD also backs products with testing data and warranties.

Schlussfolgerung

The journey through NHD’s three generations of Drahtgeflecht-Demister technology reveals a clear, purposeful path of innovation. It began with the Standard Type’s foundational efficiency, moved through the Drawer-Type’s revolutionary maintenance breakthrough, and culminated in the V-Type’s peak performance against re-entrainment. This evolution from a basic solution to a patented standard-bearer underscores a commitment that goes beyond mere product manufacturing.

NHD‘s three generations represent an unwavering pursuit of making the chemical industry more efficient, safer, and cleaner. Our enterprise standards becoming industry benchmarks prove our leadership in gas liquid separation. Contact us today at [email protected] for a custom solution that fits your operations. Our experts can review your setup and recommend the ideal demister pads. Whether it’s a Standard type wire demister for basics or a V-type for top performance, we’re here to help.