Sludge thickening plays a vital role in today’s water and wastewater treatment setups. With the growing need for eco-friendly and budget-friendly options worldwide, equipment like the mud filter press and pitched blade agitator have become essential. These devices boost the effectiveness of sludge handling by sharpening the separation of solids from liquids, cutting down on disposal expenses, and making energy use more efficient.

Overview of the Sludge Thickening Process in Water Treatment

Sludge thickening is all about boosting the solid content in sludge by taking out some of the liquid. This key step cuts down the sludge volume a lot before it goes on to further treatment or disposal.

Purpose and Role of Sludge Thickening in Wastewater Management

The main aim of thickening sludge is to shrink its volume. This helps lower the costs of moving and getting rid of it. Plus, it gets the sludge ready for later steps like dewatering or digestion by making it easier to manage.

Key Stages in the Sludge Treatment Workflow

Sludge treatment usually involves a few stages: thickening, conditioning, dewatering, and final disposal. After the first clarification, sludge goes into thickening units to lose some water. Then, it heads to conditioning tanks, often with agitators in place. Finally, it’s processed through dewatering equipment like a mud filter press.

Common Challenges in Traditional Thickening Methods

Older methods, such as gravity thickeners or flotation systems, often fall short when handling tiny particles or low solid levels. Many times, these outdated ways can’t deal with materials that won’t settle easily, even with the help of flocculants. This results in higher running costs and the need for bigger facilities.

Function and Design of a Mud Filter Press

To tackle these issues, mud filter presses provide a hands-on way to remove water effectively.

Structural Components and Operational Mechanism

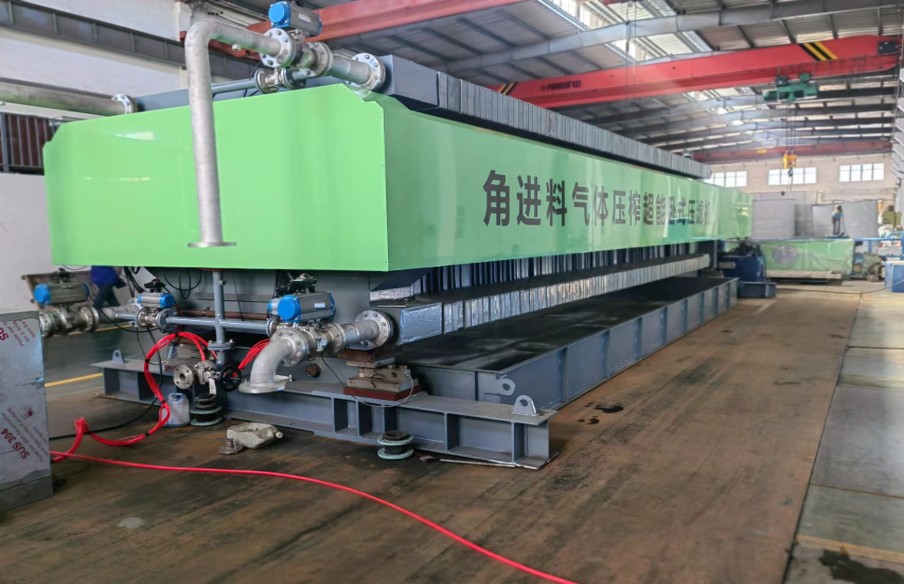

A standard mud filter press has several filter plates covered with cloths. These create chambers where slurry is fed in. First, the slurry moves into each frame’s chamber via a pipeline. It passes through the filter cloth, forming a filter cake. The leftover liquid, called filtrate, flows out through a separate pipe. Extra steps like diaphragm pressing, air drying, and automatic cake removal make the process even better.

Types of Mud Filter Presses Used in Water Treatment

Different styles meet various industry demands:

Plate and Frame Filter Press

This classic setup has plates and frames arranged alternately to hold filter cloths. It works well for some tasks but needs manual effort to clear out the cake.

Chamber Filter Press

This is a more modern type with recessed plates that create separate chambers. It seals better and offers more automation than the plate-and-frame kind.

Membrane Filter Press

This version uses bendable membranes that expand to squeeze out extra water from the cake after the first filtering. The pressure can go up to 16 kg. Air drying plays a big role here, bringing the filter cake’s moisture down to very low levels. For instance, the moisture in phosphogypsum filter cake can drop to 10%, much less than the usual 25%.

Factors Influencing the Performance of a Mud Filter Press

Many things impact how well it works: the slurry’s thickness, pressure settings, cycle duration, cloth quality, and automation degree. Today’s systems, with full automatic control and nonstop operation, deliver top output while cutting down on labor needs.

Enhancing Process Efficiency with a Mud Filter Press

Mud filter presses bring big improvements in performance when compared to older ways.

Improved Solid-Liquid Separation Capabilities

These systems use strong pressure on tightly woven cloths or membranes. This allows them to split solids from liquids very well, even with slurries having particles smaller than 5 microns. Some of these tiny bits in the mix are super fine and won’t settle on their own. In fact, certain materials won’t settle at all, even with flocculants added.

Reduction in Sludge Volume and Disposal Costs

By cutting down the moisture, there’s less sludge to move or treat later on. This directly saves money on transport and landfill charges.

Energy and Time Savings Compared to Conventional Methods

Modern presses work quicker thanks to automated feed cycles, solid squeezing setups, and better drying methods. They also clean the filter cloth on both sides automatically, refreshing it with a smart self-cleaning feature.

The Role of Pitched Blade Agitators in Sludge Conditioning

Before filtering starts, good mixing is key to spread particles evenly. Pitched blade agitators are perfect for this job.

Mixing Dynamics and Shear Control Benefits

These agitators are built to create a steady flow for circulation while applying mild shear forces. This prevents breaking the particles. They offer a strong axial flow for recycling and keep shear low, all while using little power.

Optimizing Floc Formation Prior to Filtration

Good stirring helps flocculation happen. That’s when small particles stick together into bigger clumps. This makes them simpler to catch during the filtering steps.

Integration of Agitators with Thickening Equipment

Pitched blade agitators often sit in conditioning tanks just before the mud filter presses. They fit well with existing systems, boosting the whole setup’s results.

Applications Across Various Industries

The flexibility of mud filter presses paired with pitched blade agitators makes them useful in many fields:

Municipal Wastewater Treatment Plants

These places gain from smaller sludge amounts. It takes stress off later steps like digestion or burning.

Industrial Effluent Processing Facilities

Industries such as chemical production or food making create tricky sludges. They need strong separation equipment that can manage thick, sticky fluids well.

Mining and Mineral Processing Operations

In mining tasks like managing tailings or refining ore waste, NHD has worked on over eight hundred projects. They provide solid solutions made for tough conditions.

NHD: A Trusted Supplier for Integrated Filtration Solutions

NHD shines as a top name in the field, offering a wide range of gear built for solid-liquid separation needs across different areas.

Overview of Product Series Offered by NHD

They currently have dozens of product types and hundreds of models. This ensures customers get the best setups, no matter how tricky the job is.

Filter Series & Automatic Press Filter Series

These cover vertical and horizontal choices with high automation. They’re made to give low-moisture results on a big scale. After years of growth, the market share for automatic vertical filter presses in China is as high as 50%.

Agitator & Thickener Series for Slurry Handling

The agitator blades are shaped based on the best speed zones. These designs mix well without wasting energy or harming materials.

Equipment for Sulfuric Acid Industry & Pressure Vessel Series

NHD also builds special vessels that meet tough safety rules. Chinese makers of pressure vessels must hit yearly output goals, making them the cheapest production spot globally.

Desulfurization Equipment, Filter Cloth, and Material Series

From custom cloths to desulfurization towers, NHD products reach places like the USA, Brazil, and Malaysia. This shows their trusted presence worldwide.

Conclusion

Mud filter presses and pitched blade agitators transform sludge thickening, enhancing solid-liquid separation and cutting disposal costs. Membrane presses achieve 10% moisture filter cakes, outperforming traditional methods. Pitched blade agitators optimize flocculation with uniform mixing, boosting filtration efficiency. NHD’s automated solutions, proven in 800+ global projects, ensure eco-friendly, reliable sludge management across wastewater and mining industries.

FAQs:

Q1: What is the primary benefit of using a mud filter press in sludge thickening?

A: The biggest perk is how it slashes moisture in sludge using mechanical force instead of heat drying. This cuts disposal costs and works better than old ways like gravity thickeners.

Q2: How does a pitched blade agitator support the thickening process?

A: These agitators improve mixing while keeping shear forces low. This helps small bits clump together without breaking apart, leading to better filtering results when used with equipment like mud filter presses.

Q3: Can NHD equipment be customized for specific industry needs?

A: Yes, for sure. NHD has handled over eight hundred projects in fields like phosphoric chemical work, mining, drug making, and environmental care. They craft solutions to match each client’s unique needs.