Industries worldwide are focusing more on managing wastewater effectively, especially in the area of sludge dewatering. With stricter environmental rules and rising costs, using cutting-edge equipment like the membrane automatic filter press is now a must. This piece dives into how this modern equipment boosts sludge treatment, giving a full look at how it works, its benefits, and where it’s used in various industries.

Overview of Sludge Dewatering and Its Industrial Importance

Sludge dewatering plays a vital role in wastewater treatment. It removes water from sludge to cut down its size and weight. This makes disposal or further steps much cheaper.

The Role of Sludge Dewatering in Wastewater Treatment

Good dewatering lowers the costs of moving and disposing of sludge. It also helps reduce the environmental impact of treatment plants. Plus, it makes handling easier and opens up options to reuse biosolids in farming or energy production.

Common Challenges Faced in Traditional Dewatering Methods

Old-school methods like belt presses or centrifuges often don’t cut it. They use a lot of energy and don’t always dry the sludge evenly. They also need manual work and frequent fixes. These problems have pushed the need for smarter, more efficient options.

Introduction to Membrane Automatic Filter Press Technology

To tackle these issues, the membrane automatic filter press brings in automation and stronger pressure power for better dewatering results.

What is a Membrane Automatic Filter Press?

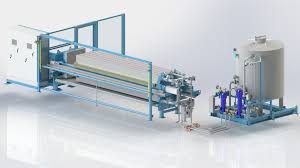

This is a high-tech filtration tool. It uses strong membranes to press out water from sludge cakes after the first round of filtering. This two-step method—filtering and then squeezing—gets the sludge much drier than older systems.

Key Components and Operational Mechanism

The setup has filter plates with built-in membranes, a hydraulic pressing unit, feeding pumps, control panels with PLC tech, and automatic systems to dump the cake. Compared to vertical filter presses, horizontal ones can cover a bigger area per unit, over 1000㎡. This leads to better savings. With the same space, costs for electrical controls, labor, and frame setups are much lower.

Differences Between Conventional and Automated Filter Presses

Unlike older chamber filter presses that need hands-on work at many points, automated ones use programmable logic controllers (PLCs) for complete control. The classic horizontal filter press has evolved over three phases. Yet, it still has big flaws. It can’t air-dry or wash. Unloading the cake is manual, and feeding is slow. Modern automated systems fix these with smart monitoring and better mechanics.

Advantages of Using Membrane Automatic Filter Press for Sludge Dewatering

Switching to this type of filter press brings many strong perks. These directly improve how well things run and support greener practices.

Enhanced Filtration Pressure and Cake Dryness

The membrane plates add extra force, often between 18 and 22 MPa, after the first filter stage. This squeezes out more water from the sludge cake. With such low water content, you might even skip the usual drying step. This saves energy and cuts down on further drying needs.

Reduced Cycle Time and Improved Throughput

Strong pressure speeds up water removal, cutting down the time for each cycle. The non-stop working style also boosts output over time. Constant operation and high production are key traits of vertical automatic pressure filters.

Lower Operating Costs and Energy Consumption

By getting sludge to have less leftover water without needing heat to dry it, plants can use much less power. On top of that, automation reduces the money spent on workers for manual tasks.

Automated Control and Minimal Human Intervention

These systems come with PLCs and easy-to-use touch screens. They let you watch things as they happen, spot problems, sound alerts, and even control them from afar. With a high level of automation and a simple control setup, plus self-checks and alarms, they’re easy to handle and very dependable.

Technical Features That Drive Efficiency

The great results come from smart design ideas made just for large industrial use.

High-Pressure Squeezing for Maximum Water Removal

Once a cake forms on the cloth after the first filter, high-pressure air or water puffs up the membranes in each plate. This squeezes the cake more. The two-step method gets the most dryness without needing heat.

Intelligent Control Systems for Real-Time Monitoring

Top-notch PLC systems handle every part, from feeding to squeezing to dumping. They keep quality steady across all runs. Touch screen-PLC setups make everything work smoothly together. They even warn about needed fixes based on sensor info.

Self-Cleaning Functions to Reduce Downtime

Automatic backwash cycles clean the filter cloths without taking things apart or scrubbing by hand. Efficient self-cleaning cloth recovery, without using water, makes the equipment last longer. It also cuts down on breaks between runs.

Application Scenarios Across Industries

The flexibility of membrane automatic filter presses makes them useful in many fields where separating solids from liquids is key.

Municipal Wastewater Treatment Facilities

In city sanitation setups that deal with huge amounts of sludge every day, automated presses give steady results. They also cut down on the need for workers, which is huge for round-the-clock operations.

Mining and Metallurgical Processing Plants

These fields create rough slurries that need tough gear to manage high solid levels. HDLY Vertical Automatic Pressure Filter, used widely in non-ferrous and smelting industries, shows how well they work in harsh settings.

Chemical and Petrochemical Industries

For tricky chemical sludges with high thickness or harsh stuff, the leaf filter works at different pressures. It handles mediums with low solids or high stickiness that are hard to filter. This ensures safe and reliable separation without harming product quality.

Operational Considerations for Optimal Performance

Even with high-tech gear making things easier, some best practices help ensure lasting success.

Installation Requirements and Space Considerations

Modern vertical designs take up less room, which is great for plants with tight space. Their small build, tiny footprint, and lower building costs allow easy setup, even in older, updated facilities.

Maintenance Practices to Extend Equipment Life

Regular checks on hydraulic parts, seals, membranes, and valves, plus swapping them out when needed, can make equipment last much longer. Built-in checks help catch problems before they turn into big breakdowns.

Safety Protocols for Automated Systems

Automation doesn’t remove all risks. Workers still need training on emergency stops and lockout/tagout steps during repairs. A unique triple pressure overload protection in the filter adds extra safety during high-pressure work.

NHD: A Reliable Supplier of Industrial Filtration Solutions

As industries look for trusted partners for advanced equipment like membrane automatic filter presses, / highlights New Hongda’s wide skills as a maker focused on top-notch innovation.

Comprehensive Product Portfolio

New Hongda provides a big range of products made for different industrial needs:

Serie de filtros

Offers basic filtration units that work for general solid-liquid separation jobs in many fields.

Automatic Press Filter Series

Has highly automated builds perfect for sludge dewatering tasks that need little human watch.

Agitator & Thickener Series

Helps with early steps by making slurry steadier before filtering starts.

Equipment for Sulfuric Acid Industry

Gives special equipment that resist damage from tough chemical settings common in acid-making plants.

Pressure Vessel Series

Made as strong containers to handle very high pressures safely for long times.

Desulfurization Equipment Series

Focuses on cleaning flue gas by removing sulfur bits, a big need for meeting global emission rules.

Filter Cloth Series

Provides different material choices suited for various particle sizes or chemical matches during processing.

Material Series

Includes parts made from tough alloys or plastics to stay strong in rough conditions.

Commitment to Quality, Innovation, and Customer Support

New Hongda blends research-driven upgrades with customer-focused help. They offer testing with small-scale machines and training after setup. This ensures clients get the best results over the equipment’s life. They also have a 1.6m² testing machine to help pick the right options.

FAQs:

Q1: How does a membrane automatic filter press improve sludge dryness compared to conventional methods?

A: The membrane plates add a second squeeze after the first filter, using air or water pressure up to 22 MPa. This extra push pulls out more water than regular chamber filters can with just hands or gravity. With much less water in the cake, it can save energy if needed.

Q2: Is it difficult to operate an automated filter press?

A: Not at all. These setups have easy PLC screens that let workers check things live using touch controls. The touch screen-PLC system ties all parts together smoothly. Most jobs, like feeding or cleaning, run on their own with little need for watching once set up right.

Q3: Can this technology be used outside municipal wastewater treatment?

A: Yes, for sure. Membrane automatic filter presses are used a lot in mining, non-ferrous smelting, chemical making, titanium dioxide work, medicine, and almost any field needing solid-liquid separation on a big scale.