In industrial filtration, achieving high efficiency, automation, and cost savings is vital. A top solution for these goals is the membrane automatic filter press. This advanced technology outperforms traditional filter presses by using membrane squeezing and smart automation systems. Learning how this equipment functions and its benefits helps industries decide whether to adopt it for their operations.

Overview of Membrane Automatic Filter Presses

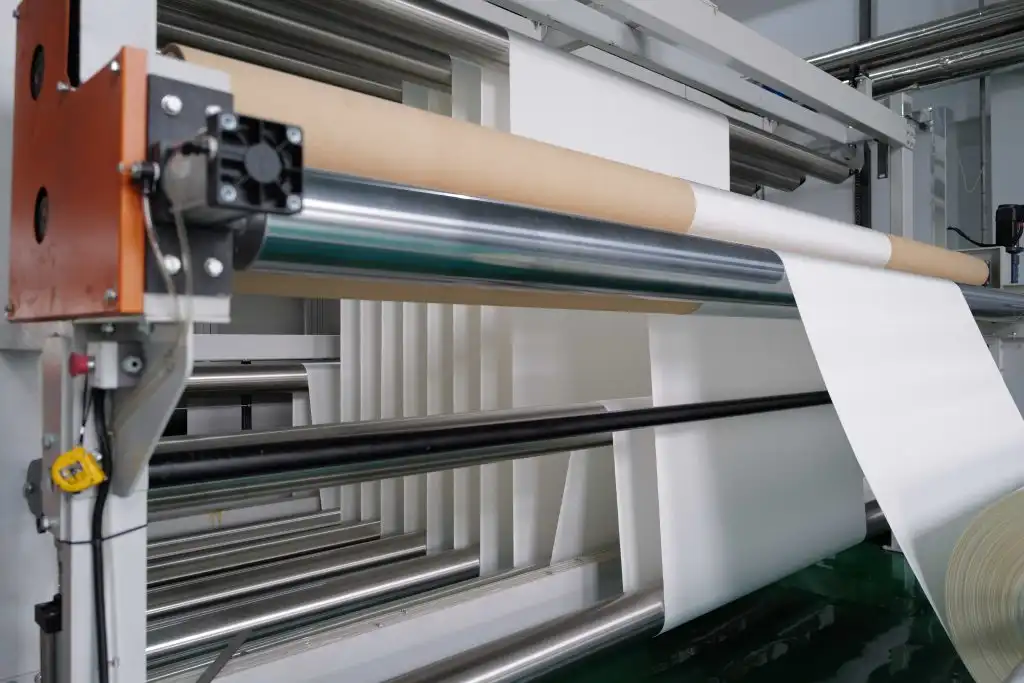

Membrane automatic filter presses are modern equipment designed for effective solid-liquid separation using mechanical and hydraulic methods.

Definition and Key Features

A membrane automatic filter press separates solids from liquids through filtration and membrane squeezing. After the first filtration step, membranes inside the plates expand to press the filter cake, lowering its water content. These presses feature high automation, often managed by PLC systems with touch-screen controls for simple use.

The HDLY Vertical Automatic Pressure Filter, created by NHD, builds on the latest global press filter technology. It serves industries like non-ferrous metals, smelting, titanium dioxide, chemicals, coal separation, food, porcelain, paper, sugar, dyes, and wastewater treatment.

Differences Between Membrane and Conventional Filter Presses

Traditional chamber filter presses use only feed pressure to remove liquid. In contrast, membrane filter presses add a squeezing step with membranes. This results in drier cakes in less time. Conventional chamber filter press plates have a shorter lifespan, while membrane presses offer consistent, faster results due to their two-stage process.

Core Components and Structural Design

The excellent performance of a membrane automatic filter press comes from its well-designed parts working together smoothly.

Membrane Plates and Their Functionality

Membrane plates are key to the system’s success. These plates have flexible membranes that inflate with air or water after initial filtration. This extra pressing ensures maximum water removal by applying even pressure across the cake.

Hydraulic System and Automation Controls

The hydraulic system controls the opening and closing of plates and inflates the membranes. Modern setups include PLC controls with easy-to-use interfaces. Operators can track performance in real time. The high level of automation, user-friendly controls, and self-diagnostic alarm system make operations safer and more reliable.

Filtration Chambers and Sealing Mechanisms

Filtration chambers form between plates when they are pressed together hydraulically. Strong sealing prevents leaks during high-pressure tasks. This creates a sealed space for efficient filtration.

How the Filtration Process Works

Understanding the step-by-step process shows why membrane automatic filter presses excel in industrial settings.

Initial Feeding and Pre-Filtration Phase

The process starts by pumping slurry into the closed chambers between plates. Solids collect on filter cloths, while liquid passes through to collection channels. Slurry flows into each filter plate from the side through pipes, beginning the solid-liquid separation.

Membrane Inflation for Secondary Pressing

When filtration slows or reaches a set pressure or time, air or water inflates the membranes in each plate. This step squeezes the cake further, removing more water.

Cake Discharge and Cleaning Cycle

Once dewatering finishes, plates open automatically one by one. The filter cake drops into a bin below. A plate puller at the end starts, pulling plates apart. The cake falls into a trough. A cleaning cycle with water or air prepares the system for the next batch.

Advantages of Using a Membrane Automatic Filter Press

Industries pick membrane automatic filter presses for strong reasons that boost productivity and save costs.

Enhanced Filtration Efficiency

Membrane pressing delivers better results than older methods. It achieves drier cakes in shorter times, perfect for operations needing high output.

Reduced Moisture Content in Filter Cakes

The cakes have much less water, sometimes eliminating the need for extra drying. This saves energy and makes handling easier later.

Lower Operating Costs Over Time

The starting price of a membrane automatic filter press might be higher than basic systems. Yet, over time, it saves money. It needs fewer workers, uses less energy, and requires less upkeep. These savings balance out the initial cost and make it a smart choice for industries.

Improved Automation and Labor Reduction

This equipment comes with handy features like automatic cake removal, cleaning cycles, and PLC controls with warning systems. These reduce the need for manual work. As a result, operations are safer and more productive. The system runs on its own, demands little effort, and is simple to use.

Common Applications Across Industries

Membrane automatic filter presses are flexible and effective. They are used in many fields that need precise separation of solids and liquids.

Mining and Metallurgy Sector

In mining, such as copper or gold processing, the press separates solids from liquids. It does this through washing, filtering, and dewatering. This makes it perfect for managing tailings or recovering concentrates in metallurgy plants.

Chemical Processing Industry

Chemicals often require careful filtration under different pressures. The press can handle materials with low solids, high thickness, or those tough to filter. It’s excellent for separating pigments or catalysts in chemical plants.

Food, Beverage, and Pharmaceutical Production

With clean designs and strong filtration, these presses work well for sugar refining, beverage clearing, or recovering pharmaceutical ingredients. Purity is crucial in these industries, and the press delivers.

Wastewater Treatment Facilities

For city or factory wastewater treatment, the press manages thick sludge. After being removed from the cloth, the filter cake settles at the bottom. This allows easy disposal while following environmental rules.

Operational Considerations for Optimal Performance

To get consistent results from a membrane automatic filter press, follow these helpful tips:

Recommended Operating Parameters

Maintain feed pressure at 0.75–0.78 MPa during the pre-filtration stage. Then, apply compression pressures of 18–22 MPa, based on the material. These settings ensure top performance.

Maintenance Best Practices

Check seals on membrane plates regularly for wear. Clean filter cloths using built-in backwash systems. Monitor hydraulic oil levels. Calibrate sensors often for accurate data.

Safety Measures During Operation

Operators should wear protective gear near moving parts. Ensure emergency stop buttons work properly. Use the built-in alarm system and triple pressure overload protection for safety.

Comparison with Other Types of Automated Filter Presses

Knowing how membrane presses compare to other designs highlights their unique benefits.

Chamber Filter Press vs. Membrane Filter Press

Chamber presses rely only on feed pump pressure. Membrane presses add a squeezing step, producing drier cakes faster and more reliably. Conventional chamber filter press plates have a shorter lifespan compared to membrane plates.

Manual vs. Fully Automated Systems

Manual systems need constant oversight, which can lead to errors. Fully automated systems reduce mistakes, run automatically, and prevent leaks or environmental issues. Automation allows 24/7 operation without fatigue-related problems common in manual setups.

Brief Introduction to NHD as a Trusted Equipment Supplier

NHD (New Hongda) is a trusted manufacturer known for innovative industrial solutions tailored to diverse global needs.

Overview of NHD’s Product Series

NHD has a wide range of products that cover many needs.

Filter Series & Automatic Press Filter Series

Includes the HDLY Vertical Automatic Pressure Filter for continuous production. It has a compact design, takes up little space, and lowers shop costs.

Agitator & Thickener Series

Designed for efficient mixing and dewatering, especially in mining and chemical industries.

Equipment for Sulfuric Acid Industry

Specialized machines built for acid-resistant environments, ensuring durability in harsh conditions.

Pressure Vessel Series

Vessels built to strict standards for safe containment across various pressures and temperatures, used in industries like petrochemicals and pharmaceuticals.

Desulfurization Equipment Series

Solutions to reduce SOx emissions from flue gases, vital for power generation and refining industries meeting sustainability goals.

Filter Cloth Series

Durable cloths compatible with various press types, offering long life and ideal permeability for coarse or fine solids.

Material Series

A broad selection of tough alloys and plastics built for harsh conditions. These materials ensure dependable performance over a long time.

Conclusion

Membrane automatic filter presses offer a strong choice for industries wanting fast, automated, and budget-friendly filtration. Their smart two-step method pairs mechanical filtering with membrane pressing. This creates drier cakes quicker than older systems. They feature high automation and easy-to-use controls. Plus, they work well in many fields like mining, chemicals, food, and wastewater treatment. These presses boost output while cutting down on worker needs and energy use. NHD’s creative designs, such as the HDLY Vertical Automatic Pressure Filter, deliver steady and durable results. By using this technology, industries can get better outcomes, follow environmental rules, and achieve lasting success.

FAQs

Q1: How does a membrane automatic filter press improve drying time compared to traditional models?

A: Its two-stage process is the key. First, it filters mechanically. Then, inflatable membranes press the cake evenly. This removes more water quickly, often without extra drying equipment.

Q2: Is it suitable for high-viscosity materials?

A: Yes, it handles low-solid, high-viscosity, or tough-to-filter materials well. This makes it ideal for slurries that clog or slow down traditional systems.

Q3: What level of automation does this equipment offer?

A: It includes PLC control panels with touchscreens, automatic operation, low labor needs, and self-diagnostic alarms. Operators need minimal interaction while keeping full control, even remotely if required.