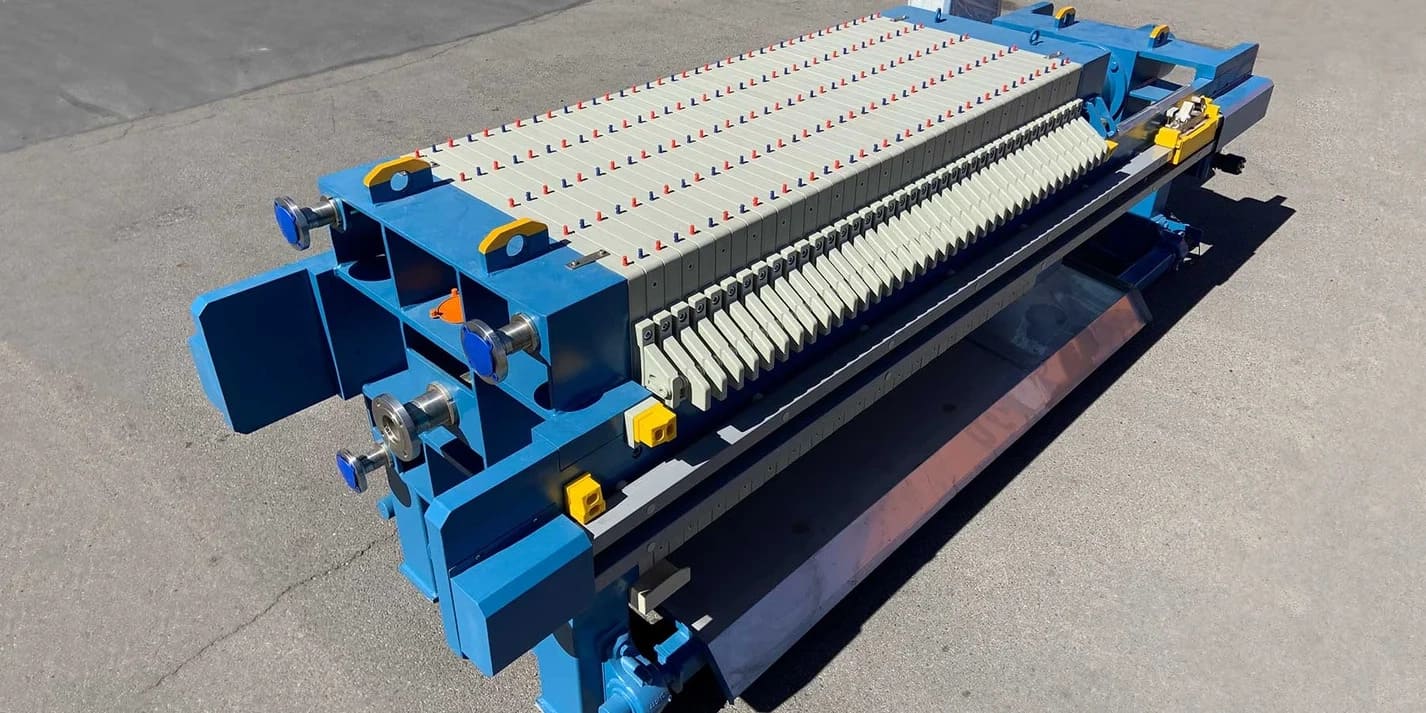

Una prensa de filtro separates liquid from solid material through pressure-driven filtration. Slurry becomes pumped into spaces created by filter plates and special cloths and solids stay behind and form thick cakes while clean liquid, called filtrate, flows out. The full cycle includes feeding the slurry, possible extra squeezing with membranes, air drying, and finally dropping the dry cakes. Main parts include the strong frame, plates, cloths, and hydraulic closing system. Designs range from simple plate-and-frame units to fully automated modern machines. Sizes go from small lab models to huge factory systems. Industries such as mining, chemical plants, and wastewater treatment depend on filter presses to produce very dry cakes and clear liquid. Special cloth choices, plate material, and automation levels can be changed to fit each job perfectly.

Visión general de la tecnología de prensa de filtro

Definition and Core Function

A filter press serves as equipment that splits liquids and solids apart. The basic idea stays simple: slurry is forced into the machine under pressure so water leaves and solids remain. Each filter press gets built according to the amount and type of slurry that needs treatment. The material spreads across many chambers made by stacked plates and cloths. Solids build up as cakes on the cloth surface, while the clear filtrate runs out through small channels. This method works especially well when factories need extremely dry solids and very clean liquid.

Components of a Filter Press

Every filter press is composed of four major parts: the frame, the plates, the piping system with valves, and the filter cloth, which have their own distinct roles. The frame bonds everything together and keeps plates perfectly lined up when heavy pressure is applied. Plates can be recessed chamber style or membrane style; membrane plates allow extra squeezing later. Filter cloths play the most important role because they catch particles and let liquid pass. Choice of cloth depends on chemical attack risk and particle size. A strong hydraulic unit pushes the plates tightly together to create sealed chambers. Pipes and valves guide the clean filtrate away quickly.

Working Mechanism and Operational Process

Filtration Cycle Steps

The filter press works in clear stages. First, slurry enters every chamber through a central feed pipe. Solids begin to collect on the cloth right away, and filtrate starts flowing out through corner ports into collection pipes. Pressure keeps rising until all chambers are completely full of solid cake. At that point, feeding stops.

Next steps can follow if needed. High-pressure water or air enters behind a flexible membrane and squeezes the cake harder to push out more liquid. After squeezing, compressed air can blow through the cake to remove even more moisture. Then, the hydraulic system opens the plate pack. A motor pulls the cloths so cakes fall down into a hopper or onto a belt below.

Step 1 – Feed: Slurry moves through pipes into each chamber. Cake starts forming while filtrate leaves immediately.

Step 2 – Diaphragm squeeze: Water fills the space behind the membrane. The membrane expands and presses the cake from above, forcing extra liquid out.

Step 3 – Air drying: Fast air flow enters from the feed port. It dries the cake and pushes remaining water from pipes and chambers.

Final step – Discharge: Plates separate. Motor moves the cloth back and forth. Cakes drop from both sides into the collection area while wash nozzles clean the cloth.

Automation Enhancements in Operation

Modern filter presses include many automatic features that save time and labor. Fast plate shifters move plates in seconds instead of minutes. Automatic cloth washers spray both sides of every cloth after discharge so cloths stay open and effective longer. Drip trays placed under the press catch leftover liquid when plates open. Special carts or conveyors carry away heavy cakes without manual lifting.

Types of Filter Presses and Capacity Ranges

Filter presses are classified by design into frame/plate-and-frame and sidebar/overhead beam types. They scale from small 150 mm lab units to large 2000 mm industrial machines for varied throughput needs.

Classification by Design Structure

Frame vs Plate-and-Frame Presses

Basic frame presses use a moving head that pushes fixed plates together. Plate-and-frame style alternates solid plates with hollow frames to create filtration space. Choice depends on how often the factory changes products or needs easy cleaning.

Sidebar vs Overhead Beam Construction

Sidebar models take up little floor space and fit tight buildings well. Overhead beam designs leave open space under the press so workers can reach parts easily during service.

Size Variants and Industrial Scalability

Smallest units use 150 mm plates for lab testing, while the largest machines use 1500 mm or 2000 mm plates and handle hundreds of tons per day, so the same basic technology can serve both research and full-scale production.

Aplicaciones en todas las industrias

Food & Beverage Processing

Filter presses are used in juice, cooking oil, and sugar plants to make products perfectly clear and accord with safety rules of food.

Chemical & Fine Chemical Production

Chemical factories recover expensive catalysts or separate valuable powders from liquid using batch filtration.

Mining & Metallurgy Operations

Mines remove water from mineral concentrates or tailings so transport costs drop and metal recovery rises.

Battery Recycling & Metal Recovery Plants

Recycling centers separate active battery material from used electrolyte solution safely.

Municipal Wastewater & Power Plants

Cities and power stations turn wet sludge into dry cake that is easier and cheaper to handle or burn.

Customization and System Integration Options

Add-on systems include automated cloth washers, drip trays, membrane squeeze for drier cake, and drying solutions. Configurations are tailored based on slurry properties through specific filter cloth and plate material selection.

Add-On Systems for Enhanced Performance

Automation Modules Available from NHD

NHD supplies full automation packages. Cloths get washed front and back automatically after every cycle. Full computer control allows continuous running with almost no worker input.

Additional Features Enhancing Usability

Drip Trays and Cake Carts

Trays stop liquid from reaching the floor. Carts or belts move heavy cakes away quickly.

Membrane Squeeze Systems

Extra squeezing step lowers final moisture when very dry cake is required.

Drying Solutions

Air blow or vacuum systems remove the last drops of water without extra heat.

Tailored Configurations Based on Slurry Properties

Filtration Media Selection (Filter Cloth)

Cloth choice affects both filtration speed and cake release. Material must resist chemicals and keep small particles while staying strong for many cycles.

Plate Material & Coating Options

Polypropylene plates resist most chemicals. Stainless steel or rubber-covered plates handle rough or corrosive slurries.

Advantages of Using Filter Press

Advantages Compared to Alternative Systems

Filter presses create drier cakes than centrifuges or belt filters. Membrane squeezing reaches even lower moisture without extra drying ovens. Filtrate usually comes out clearer and needs fewer chemicals.

Operational Efficiency Across Applications

Batch style makes product change fast and simple. Automation shortens the time between batches and raises daily output.

NHD’s Comprehensive Filtration Solutions

Highlights of Equipment

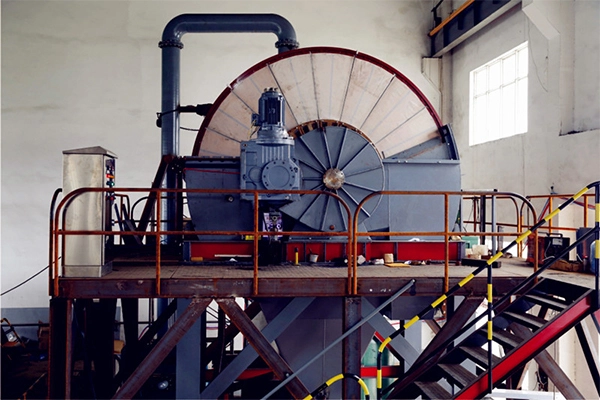

- Filtro de disco: Works continuously with rotating motion for steady output.

- Filtro de vacío de correa de goma horizontal: Handles huge volumes with little worker help.

Support Services from NHD

NHD gives full support from slurry testing to final startup. Spare parts, training, and upgrade service keep machines running for many years.

Preguntas frecuentes

Q1: What factors determine the choice between membrane vs recessed chamber filter plates?

A1: Membrane plates allow a second squeezing step that removes more water, so they suit jobs needing very dry cakes. Recessed chamber plates cost less but cannot reach the same low moisture level.

Q2: How does NHD support custom filter press configurations?

A2: NHD offers many plate sizes from 150 mm to 2000 mm, different automation levels, cloth and plate material choices, and full connection to existing plant systems after testing the actual slurry.

Q3: When should I consider using a Horizontal Rubber Belt Vacuum Filter instead of a traditional filter press?

A3: Choose the belt vacuum filter when the process must run non-stop with high daily volume and minimum worker attention, such as large mining tailings or chemical plants.