Le désembuage à palettes Chevron fonctionne sur l'inertie et la gravité des gouttelettes de liquide dans les gaz de combustion. Lorsque le gaz s'écoule à travers les canaux ondulés, les changements de direction séparent le liquide du gaz. Les gouttelettes s'accumulent sur les ailettes et s'écoulent dans le réservoir de lavage, tandis que les solides sont éliminés.

Le désembuage à palettes Chevron dépend de l'inertie et de l'effet de gravité des gouttes de liquide dans les gaz de combustion. Lorsque les gaz de combustion contenant des gouttes de liquide traversent le canal d'onde, le flux change continuellement de direction. Sous l'effet de l'inertie et de la gravité, le gaz et le liquide sont séparés. Les gouttes de liquide sont ensuite collectées sur les ailettes et drainées dans le réservoir de lavage sous l'effet de la gravité après avoir été accumulées, et les solides présents sur les ailettes sont également lavés dans le réservoir de lavage.

Applications:

Les démeubles de girouette Chevron sont largement utilisés dans les industries chimiques telles que la désulfuration des gaz de combustion humide, les tours de distillation de pétrole, les systèmes d'évaporation pharmaceutique, le traitement des brume acides, etc.

Avantage concurrentiel:

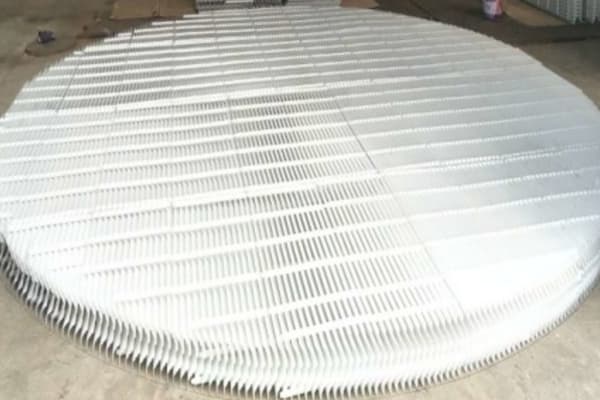

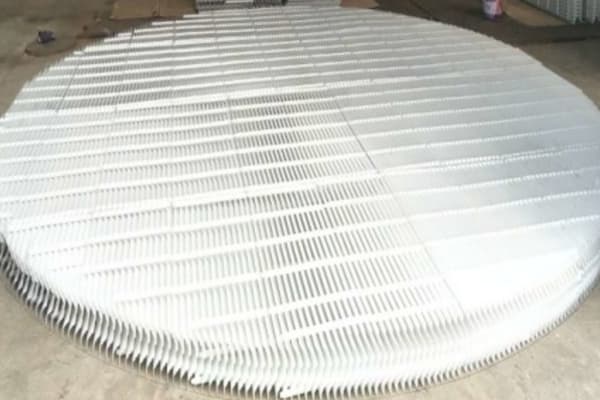

Le désembuage à palettes Chevron de NHD est doté d'un niveau tubulaire et de deux niveaux de vagues. La conception de l'aube de forme régulière permet de réduire la perte de pression, sans zone morte pour le lavage. De plus, ce désembuage ne se bloquera pas en raison de l'auto-nettoyage du désembuage tubulaire et des désembuages à vagues avec un bon système de lavage. La conception non standard permet de réduire la zone aveugle et d'améliorer la zone active.

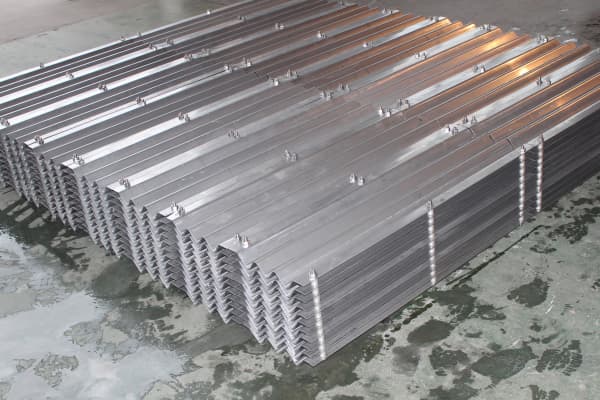

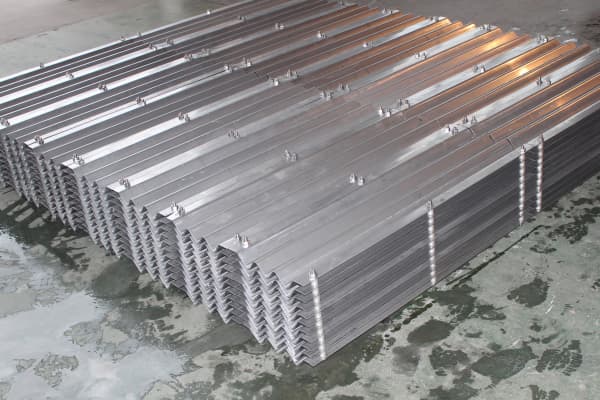

Toutes les pièces du désembuage à palettes Chevron sont formées à froid par pressage. Il n'y a pas de traitement thermique ni de processus de fabrication, de sorte que le matériau conserve ses propriétés chimiques et physiques d'origine sans modification de la structure métallographique, ce qui permet d'allonger la durée de vie.

Le produit peut être personnalisé en fonction des exigences du client.

Informations générales sur les produits:

| Lieu d'origine: | Jiangsu |

| Nom de la marque: | New Hongda |

| Certification: | ISO, SGS |

| Numéro de modèle: | / |