In early 2025, a powerful 7.7-magnitude earthquake rattled Myanmar near Mandalay, shaking the ground for millions and highlighting how fragile industrial setups can be in active seismic areas. Things like this, or the 7.4-magnitude quake in Chile back in July 2024, damaged buildings and cut power. Such quakes reveal the true dangers for mining and chemical plants. These places often handle heavy gear under steady stress from both earthquakes and big temperature changes. Ground shifts can crack foundations, while heat changes make metal parts expand and contract, leading to leaks or failures. To maintain stability and process reliability under such conditions, engineers have begun redesigning key infrastructure—especially thickening systems, which play a vital role in solid-liquid separation. This article explores how advanced thickener designs mitigate the dual threats of earthquakes and thermal stress, introducing a new benchmark for industrial resilience in challenging environments.

When the Ground Moves, So Should Your Design

Mining and chemical plants in spots prone to earthquakes face a hard mix of dangers. Earthquakes send waves that push on structures. Meanwhile, daily temperature shifts cause steel to swell and shrink. Traditional thickeners often crack under this double hit, leading to downtime and costly fixes. Let’s break down the specific damages from quakes, heat issues, and how they team up to cause bigger problems.

Seismic Damage to Traditional Thickeners

Earthquakes hit hard on thickeners. When the ground shakes, forces concentrate on fixed parts like anchors and bases. In a typical setup, a tailings thickener might see its rake arms twist or its tank walls buckle. Reports from events like the 2024 Chile quake show how mining gear suffered cracks in concrete bases and loosened bolts, halting operations for weeks. Without a flexible structural design, the entire system struggles to dissipate dynamic energy, often resulting in spills or costly rebuilds. Traditional thickeners, built with rigid tanks and fixed supports, simply cannot move with the ground. This rigidity amplifies vibration—turning small tremors into major structural failures.

Engineering studies show that in seismic zones, a standard gravity thickener may experience shear forces up to ten times normal load during a magnitude 7.0 event. The results are severe: bottom plates split, support frames deform, and operational efficiency drops by up to 30% after a major quake.

Thermal Expansion-Induced Failures

Heat fluctuations are sneaky threats in chemical and mining ops. Day-night temperature drops, or process heat from slurries, make metal expand unevenly. In a typical chemical thickener, steel tanks might grow by 0.01% per degree Celsius rise, but if parts are locked tight, this leads to buckling. Over time, welds crack, and joints leak, especially in automatic thickeners running hot fluids.

In harsh climates, like desert mining sites, temperatures swing from 5°C at night to 40°C by day. The repeated thermal cycling amplifies material fatigue. One study on mining equipment found that unchecked expansion raises maintenance needs by 25%, with failures like distorted rakes reducing settling rates.

The Synergistic Threat

Quakes and heat don’t just add up—they multiply risks. A seismic event might loosen a joint, then thermal cycling widens the gap into a full crack. In tailings thickeners, this synergy has led to spills in past incidents, like those in seismic mining areas. Data from the 2025 Myanmar quake aftermath shows facilities with rigid designs faced 40% more downtime than flexible ones. As a thickener manufacturer, NHD recognizes this overlap, pushing for designs that handle both.

NHD Thickener Anti-Seismic Design Philosophy

NHD stands out as a thickener manufacturer by baking resilience into its core designs. Drawing from over 200 patents, their seismic zone thickeners use flexible elements to soak up shocks. This approach keeps gravity thickeners running in tough spots, like Indonesia’s quake-prone mines.

Flexible Bottom Patent Technology

At the heart of NHD’s lineup is the flexible bottom tech, a patented feature in our thickeners. Unlike conventional rigid bases that crack when subjected to movement, the flexible bottom allows controlled micro-shifts in response to ground motion, effectively releasing structural stress. In a 32-meter-diameter gravity thickener, this innovation enables the tank to absorb vibrations from a magnitude-7.0 earthquake without deformation, maintaining steady settling performance. Under such stability, solids can concentrate up to 15 times faster than in standard designs.

For chemical thickeners that handle corrosive slurries, this bendiness means longer life—up to 20 years, compared with about 10 for rigid counterparts. Building on this base, NHD adds layers of protection through frames that dampen vibrations, creating a comprehensive seismic-resistant thickener system engineered for long-term reliability.

Rigid Bottom vs. Flexible Bottom

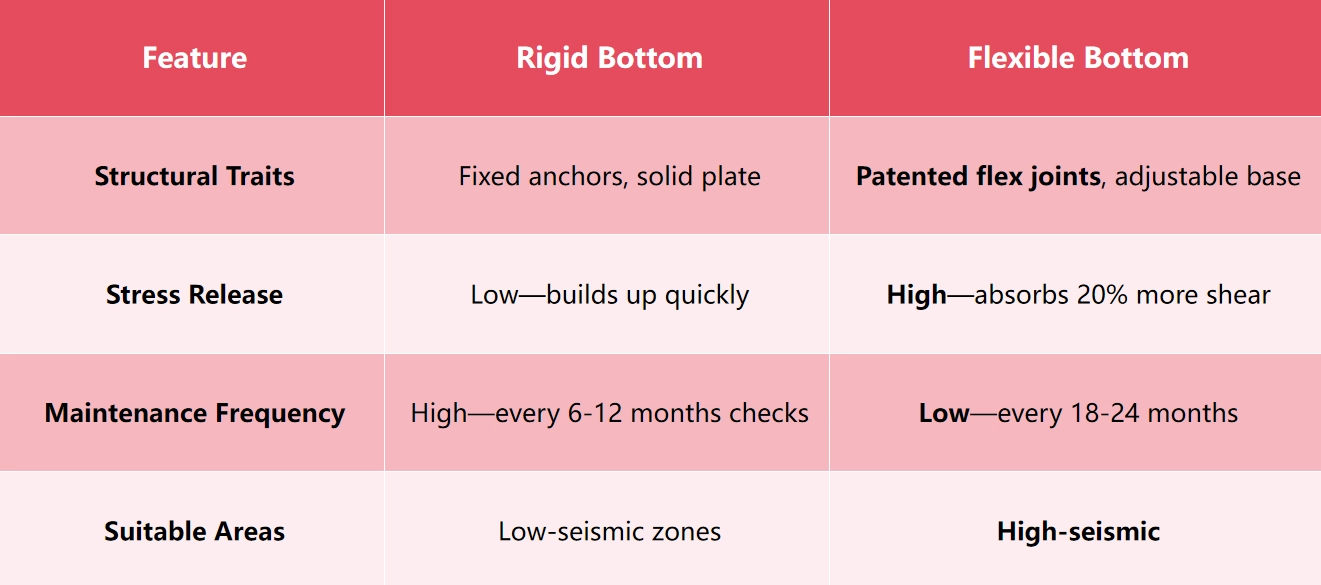

Choosing between rigid and flexible bottoms matters in seismic zones. Rigid designs lock everything in place, fine for calm areas but risky elsewhere. Flexible ones, like NHD’s, adapt and last longer. Here’s a quick look:

This table shows flexible bottoms cut maintenance by up to 50%, ideal for thermal stress thickeners in hot, shaky regions. Field trials confirmed that these structures withstand up to ten times higher compression loads without structural failure.

Combat Thermal Expansion in Thickener Operations

Beyond quakes, heat is a silent foe in thickener ops. NHD’s thermal-stress-resistant thickeners fight back through advanced material selection and precision expansion joints that maintain structural integrity even under extreme temperature fluctuations in mining and chemical plants.

Material Selection for Thermal Stability: This alloy offers both corrosion resistance and low thermal expansion—approximately 13 micrometers per meter per°C, compared with 17 µm/m·°C for carbon steel. In a 42-meter tailings thickener, it prevents warping, maintaining seal integrity. This choice boosts lifespan by 30%, cutting rust issues in humid spots. Field data show no measurable deformation after years of 30-50°C swings.

Integrated Solutions in Practical Applications

NHD doesn’t just design—they deliver in real projects. Our thickeners blend anti-seismic and thermal features for seamless ops. Let’s see this in action through a key case and the broader wins.

Case Study: Lygend Mining Indonesia Project

In Indonesia’s nickel-cobalt smelting for Lygend Mining, NHD supplied 32m, 36m CCD, and 42m thickeners. Sited in the Pacific volcanic ring, the area faces high quake risks. Despite the challenges posed by the earthquake zone, NHD’s duplex steel and innovative designs ensured no structural issues. Particularly during the pandemic period, it provided robust technical support and equipment reliability. The thickeners handled slurry separation flawlessly, boosting phase one output beyond targets. Flexible elements absorbed potential shakes, while thermal stability managed tropical heat. This project cut civil work time significantly, saving months on setup.

Proven Results and Measurable ROI

NHD thickeners deliver fast payback and long-term value.

In one case at Lygend, they cut maintenance costs by 25% while achieving throughputs up to 15 times higher than standard units. Enhanced settling and up to tenfold compression efficiency translate into around 20% energy savings per ton of material processed—a direct gain in operational efficiency and sustainability.

Key advantages include:

- Lower Upfront Investment: Each unit is custom-engineered to match site demands, avoiding over-design and unnecessary cost.

- Long-Term Reliability: Fewer repairs and component replacements, even in high-seismic or high-temperature zones.

- Higher Productivity: Automated control systems maintain uptime above 95%, even under heavy load conditions.

As a dedicated thickener manufacturer, NHD designs and adapts its systems for gravity, chemical, and tailings applications, proving its value in the most demanding industrial environments.

Conclusion

NHD thickeners effectively counter earthquakes and thermal expansion with innovative flexible bases, vibration-damping frames, and thermally stable materials. In seismic-prone areas, these features represent a significant advancement, helping operators sidestep issues common in rigid systems while achieving greater efficiency and cost savings.

Founded in 1992, NHD is a global provider of chemical and equipment, holding numerous patents and ISO certifications. Through comprehensive EPC+M+O services encompassing engineering, procurement, construction, management, and operations, we provide end-to-end solutions for industries such as mining and chemical engineering, serving partners worldwide.

Considering upgrading your equipment? Contact us at [email protected]. Our experts are ready to provide customized guidance and support to enhance the durability and productivity of your facility.