Industrial filtering is very important in many fields. These include wastewater cleaning, mining, and chemical making. Among the many kinds of filtering equipment, belt filters and filter presses are two of the most common choices for splitting solids from liquids. These machines handle different materials and work needs. But they are quite different in how they are built, how they work, and where they fit best. This piece looks closely at what sets a belt filter apart from a filter press. It checks their ways of working, how well they perform, and which industries suit them. By knowing these gaps, companies can pick the right equipment wisely.

Overview of Belt Filters and Filter Presses

Filtering equipment is needed to separate solids from liquids. Both belt filters and filter presses have their own special places in factory uses. To see their differences clearly, we must first explain what each one is. We also need to grasp their basic builds.

What is a Belt Filter?

A belt filter is also called a belt press. It is a non-stop filtering system. People use it mostly to remove water from sludge or thick mixes. It has many belts. These belts move through different areas. The areas include gravity draining, light pressing, and strong pressing. This pulls water out from the stuff. This equipment is liked a lot. Why? It can deal with huge amounts of material all the time without stopping. So, it is a top pick in wastewater plants and other places that need big output.

What is a Filter Press?

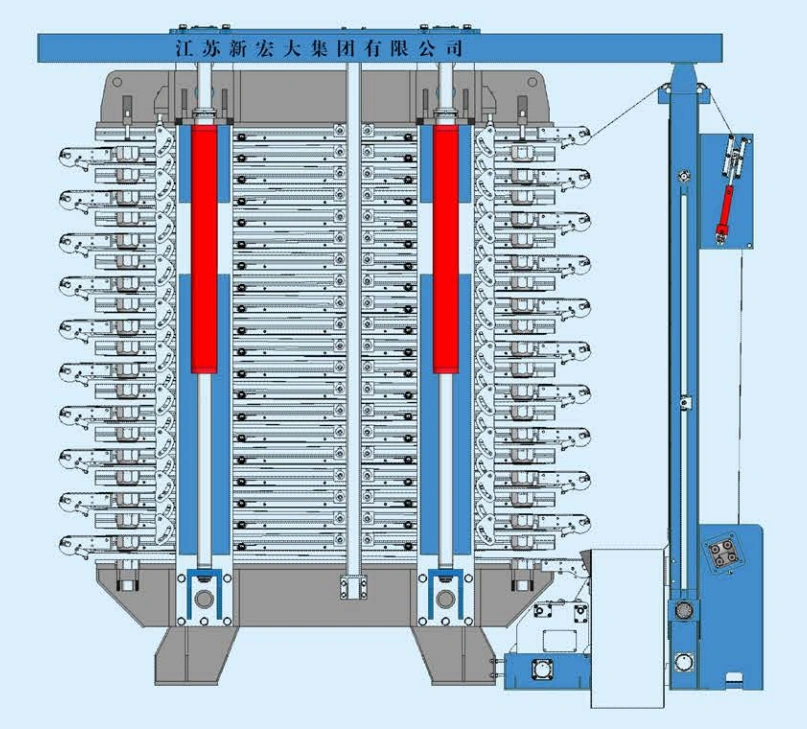

A filter press works in batches. It is not continuous. It uses many plates and frames. Or it uses sunken chambers. These catch solids. The liquid goes through a filter cloth. A solid “cake” forms. You can take it out easily when the round ends. Filter presses are famous for making very dry cakes. They do better than many other systems. This makes them great where low water in the end product matters a lot.

Operational Mechanisms and Process Flow

Knowing how each machine runs helps us judge what fits a job. Let us look at how they work differently. We will also check speed and output.

How Each Equipment Functions

Belt filters start by putting thick mix on a moving belt. Gravity pulls out free water first. Then, the belt keeps going. Rollers push harder and harder. They squeeze more water out. This goes on without pause. It gives steady dewatered stuff. But a filter press works in steps. You pump the mix into spaces between plates. Pressure pushes liquid through the cloth. Solids stay behind. When spaces are full, the step stops. You remove the cake. Then you clean. After that, you start again. This batch way takes more time. Yet, it lets you control the filtering exactly.

Process Efficiency and Throughput

Belt filters win in speed. They run all the time. So, they handle big amounts of mix non-stop. This suits factories with steady flows. Filter presses are batch types. They need breaks to dump cake and clean. This lowers total speed. But they make up for it. How? They dewater better. The end product has less water.

Comparison of Performance Characteristics

Besides how they run, many performance points set them apart. These cover filtering quality, upkeep needs, and running costs.

Filtration Quality and Cake Moisture Content

A big gap is in filtering quality. Also in cake water level. Filter presses make drier cakes. Often, water is just 20-30%. Why? High pressure is used. Belt filters work well too. But cakes are wetter. Water is 40-60%. Their pressing is not as strong. For fields where dryness is key, like mining or chemical work, a filter press may be better.

Maintenance Requirements and Downtime

Upkeep is important to think about. Belt filters have moving parts. They run all the time. So, they need regular care. This stops belt wear. It keeps rollers in line. But their build lets you reach parts easily. So, stop time for fixes may be short. Filter presses are simpler in some ways. They have fewer moving bits. Yet, they can have longer stops. Why? You must clean plates. You replace cloths after each batch. This is hard in busy runs.

Energy Consumption and Operating Costs

Energy use differs too. Belt filters use less power for each bit of material. They depend on gravity first. Then mild pressure. Filter presses need more power. They use strong hydraulic or machine pressure. This gets drier cakes. Running costs for filter presses can be higher. Why? Batch work needs more workers. Cloths get changed often. Companies must balance these costs. They gain from drier output.

Application Suitability Across Industries

Picking between a belt filter and a filter press depends on the field. Or on the job needs. Each shines in its own spots. This is based on material traits and goals.

Ideal Use Cases for Belt Filters

Belt filters fit best where non-stop work on big slurry amounts is needed. You see them a lot in city wastewater plants. There, they remove water from sludge. They are in food making too. And in pulp and paper. Steady output is vital there. They handle soft, not rough materials well. High dryness is not the main worry.

Ideal Use Cases for Filter Presses

Filter presses are great where super dry cake matters. They are common in mining. There, they dewater mineral bits. In chemical fields, they process fine or dangerous stuff. In drug making, exact splitting is needed. Batch runs help with materials that need set conditions. Like high pressure or heat control.

NHD: A Trusted Supplier of Industrial Filtration Equipment

Picking filtering equipment is big. Working with a good supplier is just as key. NHD is a top name in industrial filtering answers. They give many products that fit different work needs.

Comprehensive Product Portfolio from NHD

NHD has a wide choice of filtering equipment. This includes belt filters and filter presses. All are made for many fields. They focus on quality. So, each equipment is strong and works well. This helps firms make processes better. Do you want non-stop setup for big dewatering? Or batch for exact splitting? NHD gives custom answers. They add expert help and service. They also offer Filter Series, Automatic press filter series, Agitator&thickener series, Equipment for sulfuric acid industry, Pressure vessel series, Desulfurization equipment series, Filter cloth series, Material series.

Summary of Key Differences Between Belt Filters and Filter Presses

To help choose, let us go over main gaps again. Belt filters run non-stop. They give higher speed. They use less energy. But cakes are wetter. Filter presses use batches. They make drier cakes. Yet, speed is lower. Energy use is higher. Upkeep differs too. Belt filters need steady checks on moving parts. Filter presses need deep cleaning between rounds. In the end, pick based on what matters. Like amount, dryness, and cost.

FAQs

Q1: What factors should I consider when choosing between a belt filter and a filter press?

A: Many things matter in this pick. Think about material amount. Desired cake water level. And work budget. If non-stop work and high speed are top, go for belt filter. But if super dry cake is needed, pick filter press. Also look at energy costs. Upkeep skills. And material details. Like particle size and roughness.

Q2: Are belt filters easier to maintain than filter presses?

A: Usually, belt filters are simpler to care for in reach. Parts like belts and rollers are open. You can check or swap them fast. But they need ongoing watch. This stops wear and bad line-up. Filter presses have less moving bits. Yet, care is more work-heavy. You clean plates. Change cloths after each round. This can mean longer stops.

Q3: Which equipment offers better energy efficiency?

A: Belt filters are often better in energy save. They use gravity for first water pull. Then mild pressure. This takes less power per material bit. Filter presses need high pressure for dry cakes. So, they use more energy. This raises costs over time. If saving energy is big, belt filter may cost less.