Inside the massive reactors of a chemical plant, various raw materials undergo chemical reactions. In a chocolate factory, sweet chocolate paste swirls in its containers, waiting to solidify into silky candies. Even in the metallurgical industry, boiling molten metal awaits perfect uniformity. These seemingly diverse industrial scenes all rely on a common core device: the industrial agitator. Far from simply stirring, it is the cornerstone of efficient and uniform mixing in modern industrial production, directly impacting product quality, production efficiency, and enterprise costs.

Industrial Agitator: The Art of Mixing Everywhere

An agitator’s primary function is to accomplish mixing, heat transfer, mass transfer, and chemical reactions in an efficient and uniform manner. As a result, industrial agitators are extensively utilized across many sectors, including wastewater treatment, mining, metallurgy, food, and chemicals.

The Chemical Industry: The main industry in which tank agitator mixers are used is the chemical sector. Whether in coatings, cosmetics, pharmaceuticals, or plastics, mixing liquids, powders, and gases requires precision and speed. Incomplete mixing may compromise product quality—or, in the worst case, create serious safety risks.

Food and Beverage Industry: The richness of yogurt, the smoothness of ice cream, and the flavor of beer all rely on mixing. In the food industry, mixer equipment must not only mix evenly but also meet extremely high hygiene standards, often requiring gentle mixing to avoid damaging delicate ingredients such as fruit pulp.

Metallurgy and Mining: To maximize precious metal recovery, mixers in large leaching tanks ensure thorough contact between ore particles and chemical reagents. Their impellers must also withstand extreme conditions of intense corrosion and abrasion.

Environmental Water Treatment: Activated sludge and wastewater are thoroughly mixed in sewage treatment plants by mixers, which facilitate the microbial breakdown of organic matter. This is an essential step in the purification process.

Industrial Agitator: The Key to Efficiency and Cost

In modern industrial production, efficiency and cost control are often the core of a company’s competitiveness. As a key piece of equipment in many processes, the selection and design of tank liquid agitators play a decisive role in this equation. A well-designed and impeccably crafted blending tank agitator does far more than simply mix; it enhances production value in multiple dimensions:

Better Product Quality: Consistent mixing is a must for tons of products. A good mixer equipment spreads reactants, additives, or ingredients nicely and evenly, wiping out batch differences, clumps, weird tastes, or weak performance from dead zones. The result is higher-quality end products and fewer customer complaints or defective goods.

Faster Production: Time is money. Strong agitation boosts mass and heat transfer, speeding up reactions, dissolving stuff quicker, or mixing things faster. Shorter batch times mean each reactor can handle more cycles. It’s a straight-up win for production capacity, giving companies the gear to jump on market openings.

Lower Energy Bills: Energy’s a big chunk of mixing costs, and companies feel that pinch. Old-school or poorly chosen agitators often crank high-speed, power-hungry motors to make up for bad design, racking up huge electric bills. But a smartly designed agitator, built to match the material and process goals, gets the same or better results while sipping way less power. Those savings add up big over time, keeping costs down for good.

Longer Equipment Life: A well-built agitator runs smoothly, shakes less, and spreads forces evenly. That means less wear on key parts like shafts, gearboxes, bearings, and seals. The tank liquid agitator and its tanks last way longer, slashing repair bills and losses from unexpected downtime for part swaps. It’s a solid way to keep long-term costs in check.

Industrial Agitator Buying Guide

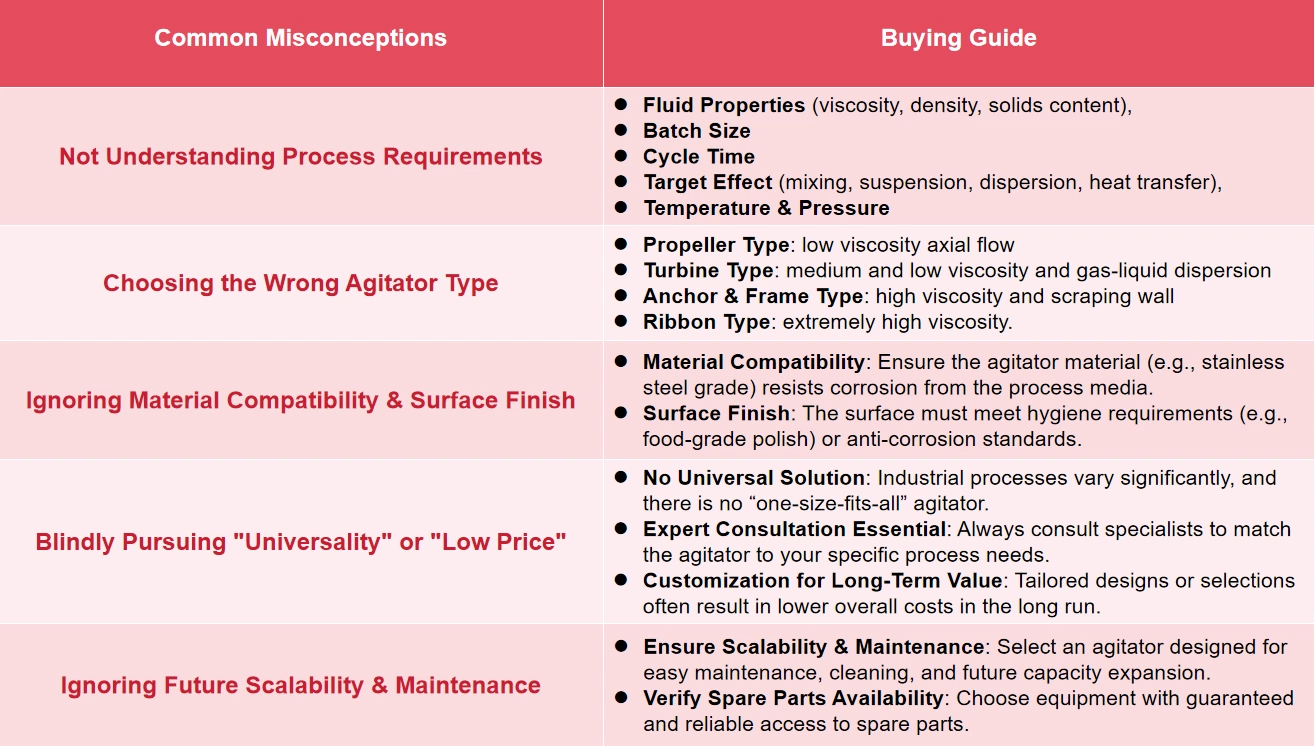

Selecting the right agitator is a technical task, and blindly choosing one may result in poor results. Here are some common misunderstandings and how to avoid them:

NHD’s Advanced Agitator Solutions for Chemical Applications

As a powerhouse in agitator tech, NHD has built machines that tackle the toughest jobs in factories worldwide—from phosphoric acid plants to power stations. Whether you’re curious about the clever designs that make mixing a breeze or the real-world stories of gear that lasts, dive into our breakdown: from cutting-edge portfolios to battle-tested applications. Let’s mix it up and see what makes NHD’s agitators stand out.

Advanced Agitator R&D Technology & Portfolio

NHD’s agitators cater to diverse industrial needs, offering top-entry, side-entry, and bottom-entry models for liquid-liquid, solid-liquid, gas-liquid, and multi-phase mixing, with power outputs from 1.5 to 1000 kW and speeds of 0.01–3000 r/min.

NHD’s R&D leverages the ADV Testing Bench and CFD Fluent simulations for optimized agitator design. The ADV bench, one of China’s largest, tests impellers up to 1800mm across 600mm, 1200mm, and 1800mm tanks. It analyzes 3D flow fields and power (N=M*U*π) using torque sensors and speed detectors, ensuring scalable, efficient designs. Tests include baffles, novel impellers, and tank bottom effects, with nine impellers for comparative studies. CFD Fluent models fluid dynamics, refining impeller geometry for enhanced mixing. NHD’s designs scale up to 36m impellers, leading the industry in large-scale applications.

High Viscosity & Corrosion Resistance

NHD agitators feature bottom-entry designs that process dense slurries in reaction vessels. A sealed-liquid protection system is equipped to prevent gas leakage by maintaining sealing fluid pressure higher than the pipeline gas intake pressure. The system is furnished with real-time monitoring and alarms for liquid level, pressure, and flow, ensuring operational safety and early fault detection. To ensure corrosion resistance, shafts and blades are clad in rubber lining, complemented by high-grade stainless steels—including 316L and 904L. These agitators perform reliably in demanding environments, such as phosphoric acid plants or wastewater treatment facilities.

Low Maintenance & Cost Efficiency

NHD agitators are engineered for low maintenance and cost efficiency, featuring a streamlined design with fewer moving parts to minimize breakdowns. Some models include self-diagnostic systems that detect potential issues early, reducing downtime.

For instance, at the Wengfu Dazhou Chemical Plant, NHD designed an agitator with a mechanical seal that prevents sulfur dioxide gas leaks, enhancing worker safety by eliminating the need for constant use of gas masks. The patented quick-change mechanical seal allows maintenance without draining materials or entering the reactor, as a lifting device raises and rotates the motor-gearbox assembly. Additionally, NHD employs a hollow shaft design, prioritizing stiffness over strength for economic benefits, as low-probability breakage is more cost-effective than frequent bending repairs. This design also enables reaction gases to be delivered directly through the hollow shaft, eliminating external piping. With readily available materials like high-quality stainless steels, NHD agitators ensure reliable performance without reliance on costly imports, making them a preferred choice in demanding industrial applications worldwide.

Proven Global Applications

NHD agitators hold a significant market share in China, serving phosphoric acid and alumina plants, while also demonstrating a strong global presence across diverse and demanding projects. Our equipment supports copper smelting in Russia, nickel ore processing in Indonesia, cobalt-nickel smelting in Papua New Guinea, and copper-cobalt operations in the DRC. With over 800 projects worldwide—including large-scale phosphoric acid facilities and non-ferrous metallurgy plants—NHD agitators are trusted in extreme conditions and complex processes, backed by collaborations with international partners like MCC Ramu and CMOC.

Conclusion

NHD is the industry benchmark for global industrial liquid agitation and mixing systems, especially in the field of co-current agitator technology. Since its establishment, the company has been continuously innovating for more than 30 years and has earned an excellent reputation both at home and abroad. As one of the leading agitator manufacturers, NHD consistently delivers high-performance, reliable solutions tailored to diverse industrial applications. To satisfy the more general needs of the mining and metals industries, NHD offers sophisticated metallurgical equipment in addition to agitator solutions. NHD’s Co-Current Agitators are a reliable partner for alumina producers worldwide and other process industries. For additional information about our agitator solutions, please get in touch with our professionals at [email protected].