Automated filter presses clearly perform better than manual versions in many ways. They raise work speed, keep results steady, cut down expenses, and lower dangers. Automation shortens cycle times, boosts total output, reduces mistakes from workers, and makes the job less hard on the body. Smart control units save power and spot problems early, which brings operating costs lower. Newer layouts, such as vertical styles, take up less room and stay ready for use longer. High-pressure horizontal units handle tough materials well. All these points make automated filter presses the top choice for large industries like wastewater plants, mining sites, and chemical factories where steady work, growth options, and lower long-term costs matter most.

Challenges of Manual Filter Presses in Industrial Applications

Limitations in Operational Efficiency

Manual filter presses can cost less at the start and suit small jobs, yet they create real problems in bigger factory settings. Workers must stay involved in every step, from pumping in the slurry to scraping plates and removing the solid cake. This constant need for hands-on work slows the whole filtration process greatly.

Because operators differ in skill and energy, results change from one cycle to the next. Such changes hurt product quality and often force extra work or waste material. Unsteady cycle times also make planning harder and lower overall factory output.

Labor Intensity and Safety Concerns

Manual filter presses demand heavy physical effort, especially when removing dried cake and washing filter cloths. The repeated motions raise the chance of back or arm injuries over time. Human mistakes happen more often without automatic guards, and those errors can damage equipment or cause accidents.

If plates sit wrong or pressure settings vary, serious breakdowns or worker harm can follow. These dangers explain why large plants avoid manual systems when strict safety rules must be followed.

Maintenance Complexity and Downtime

Manual units need regular cleaning and adjustments that often require taking the whole machine apart. This work stops production for long periods and cuts daily running time. Finding the real cause of problems stays difficult without smart tools, so repairs take longer than necessary.

Since manual presses lack early warning systems, problems only get fixed after they appear. That approach leads to higher repair bills and sudden stops in work.

Enhanced Cycle Speed with Automated Filter Presses

Faster Filtration Cycles Through Automation

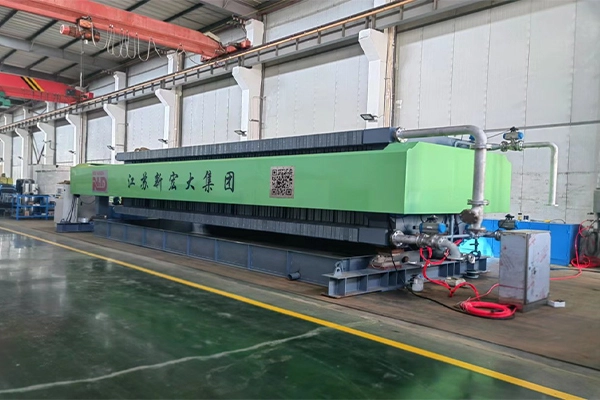

Automated filter presses shorten each cycle by removing the need for workers during key steps. Machines can move quickly through feeding, pressing, washing, drying, and cake removal without pause. Units like the Filtro de Pressão Automática Vertical HDLYName from NHD run smooth, repeatable patterns that finish tasks in less time.

Control screens and built-in programs manage every part of the process with exact timing. This setup removes slow manual jobs such as plate cleaning or cloth washing that often hold up older systems.

Continuous Operation for Higher Productivity

Many automated filter presses keep running without long breaks, especially vertical models where chambers work on their own. One chamber can release finished material while others keep filtering new batches.

This independent style cuts waiting time between cycles and raises daily production totals. The HDLY Vertical Automatic Pressure Filter, built by NHD, serves many fields including non-ferrous metals, smelting, titanium dioxide, chemicals, coal cleaning, food, ceramics, paper, sugar, dyes, and wastewater treatment. It stays active even when conditions change.

Improved Efficiency and Process Consistency

Reduced Human Error and Process Variability

Automated filter presses stand out by cutting down mistakes that people make. Machines follow the same steps every time, so pressure, timing, and release stay exact across all cycles.

Steady operation brings better final products and less wasted material. Results stay reliable from one batch to the next.

Scalability for High-Capacity Industrial Use

Automated systems grow easily with factory needs. The Filtro Prensa de Placas Horizontal de Super Pressão handles large volumes and runs without stopping. It works at pressures up to 22 MPa, perfect for hard jobs in mining or city wastewater plants.

Horizontal units can cover more than 1000 square meters in one machine, which lowers cost for each ton of material processed.

Lower Energy Consumption and Operational Costs

Optimized Energy Usage Through Intelligent Control Systems

New automated filter presses use power wisely. Smart controls adjust motors, pressure cycles, and drying times to save electricity while keeping strong performance.

Some models cut the need for air compressors or heavy hydraulic units through clever mechanical parts. Lower power use reduces monthly bills and helps meet green goals.

Decreased Labor Requirements and Maintenance Demands

Automated filter presses need far fewer workers on duty. Programmable controllers run the entire process without constant watching.

Many units also watch themselves for early signs of trouble. The HDLY Vertical Automatic Pressure Filter offers high automation levels plus clear screens with self-check and warning systems. These tools spot small issues before they grow large, cutting sudden breakdowns and making equipment last longer.

Advanced Design Features Enhancing Overall Performance

Vertical automatic pressure filter and horizontal plate filter press separately have its own advantages for different designs.

Vertical Configuration Benefits in Modern Systems

Key Advantages of Vertical Automatic Pressure Filters:

Vertical stacking saves floor space, which helps factories with tight rooms. Smaller size and lower building costs make them good for adding to older plants or growing output without new buildings.

Separate chambers also stop different materials from mixing, an important point when handling dangerous or varied products.

Enhanced Uptime with Modular Design:

Chambers work alone, so one can be cleaned while others keep running. This setup keeps most of the machine active during service.

Open layouts give easy reach to inner parts for checks or quick part swaps.

Horizontal Plate Filter Press Innovations for High Pressure Applications

Features of Super Pressure Horizontal Plate Filter Press:

Built for tough slurries with tiny or rough particles, this model combines strong build with flexible use. It removes more water than standard chamber presses and works well in hard conditions.

Heavy-duty structure stands up to daily wear in places with chemicals or grinding materials.

Application Scenarios Where Automation Delivers Value

Different types of automated filter presses have different fields they are suitable for.

Industries Benefiting from Automated Filter Presses

Automated filter presses fit best where steady high output is needed. Common areas cover:

- Wastewater plants that need reliable sludge drying ;

- Mining sites with tight schedules for solid-liquid separation;

- Chemical factories where every batch must match quality standards

These machines prove their worth across many sectors.

When Manual Systems May Still Be Appropriate

Manual filter presses remain useful in certain cases:

- Small test runs or low daily volume

- Tight budgets where the extra cost of automation takes too long to pay back

In those situations, simple manual units may fit better despite slower speed.

FAQ

Q: How does an automated filter press reduce labor costs compared to a manual press?

A: Automated filter presses handle every stage through programmable controllers, so workers spend much less time watching or operating the machine.

Q: Can NHD’s Vertical Automatic Pressure Filter handle high-solid slurries?

A: Yes. The vertical chamber layout and separate controls allow efficient work with thick, high-solid mixtures.

Q: What industries are best suited for NHD’s Super Pressure Horizontal Plate Filter Press?

A: Mining, chemical production, metal processing, and wastewater treatment benefit most, especially when fine particles or harsh materials require strong pressure.