In the chemical processing field, accuracy and steadiness are incredibly important. Whether it’s in drug making or oil refining, keeping products pure while making operations smoother is always a tough task. One key area that often gets ignored in chemical production is combining strong solid-liquid separation tools with top-notch mixing methods. Tools like the vacuum belt filter and pitched blade agitator help make processes easier and also guarantee better product quality and dependable results.

Filtration: A Critical Step Following Chemical Mixing

Filtration is a basic step in chemical work, especially when it comes to splitting solids from liquids during or after mixing.

Importance of Solid-Liquid Separation in Chemical Processing

Solid-liquid separation is vital for cleaning up products, getting back useful materials, and setting things up for the next steps. In fields like medicine, plastics, and water cleaning, careful filtration decides how good the final item is and whether it meets strict rules.

Challenges Faced Without Proper Filtration Systems

If you don’t have solid filtration setups, chemical work can run into problems. These include dirt buildup, uneven product batches, equipment getting clogged, and more time wasted on manual fixes. Such issues raise costs and can even put safety at risk.

Working Principles of a Vacuum Belt Filter

The vacuum belt filter has become a top pick for ongoing solid-liquid separation in tough settings.

Mechanism of Continuous Filtration

A lengthy piece of filter cloth moves like a rolling belt in the machine’s center. It handles the full process automatically, from adding material to filtering, washing, removing waste, and cleaning the cloth. As the mix moves along, a vacuum box below the belt pulls hard. The liquid passes through the cloth into a channel, then into the vacuum box via a drain hole. Finally, it’s released and gathered from the box’s bottom.

Key Components and Their Functions

This setup has a rubber belt with slots for draining, vacuum boxes for pulling apart materials, sprayers for washing the solid layer in stages, rollers to move the cloth, tension tools for steadiness, and scrapers to clear off the solid bits. There’s also a correction unit. It fixes any shifts and brings the cloth back to the filtering spot to start over.

Advantages Over Traditional Filtration Methods

Older horizontal filters with round discharge blades leave behind a 5-10 cm layer of solid waste. But the belt filter clears it all away. It also cleans the cloth on both sides very well, cutting down on water use. Compared to outdated tools like rotary drum filters or plate-and-frame presses, this boosts output a lot.

Integration of Vacuum Belt Filters with Chemical Mixers

To get the best results in chemical plants, pairing filtration tools with mixers helps keep the work flowing smoothly.

Compatibility with Various Mixer Types

Vacuum belt filters work well with fast-spinning mixers, reaction containers with built-in stirring, batch blending units, and especially those with pitched blade agitators. Their flexible build makes them easy to add to both new and old systems.

Enhancing Process Flow and Operational Continuity

These filters allow nonstop filtering without pausing the mixing or needing hands-on work to clear solids or clean the cloth. The vacuum box can be lifted or lowered fast. This ensures smooth switches between different steps in the process.

Reducing Downtime and Maintenance Requirements

Simple to run, with only a few moving parts and low upkeep costs, vacuum belt filters are perfect for nonstop industrial settings where keeping things running is a must.

Impact on Efficiency and Product Quality

Using advanced filtration setups greatly boosts both the amount of work done and the quality of the final goods.

Improved Yield Through Consistent Filtration

With exact control over the thickness of the solid layer, the equipment adapts well. It manages the layer’s depth, ensuring even separation. This gets the most material back while cutting down on waste.

Reduction in Contamination Risks

Running continuously in a closed setup cuts down on contact with outside dirt. Working fully sealed, with no leaks or harm to the surroundings, meets the tough cleanliness rules needed for medical or food-safe products.

Energy and Resource Optimization

The washing works well with a multi-step reverse flow method. It uses less water but cleans better. Also, a heat-keeping vacuum box cuts down on buildup caused by cooler temperatures. This saves energy, especially in cold conditions.

The Role of Pitched Blade Agitators in Enhanced Mixing

While filtration makes products clearer and boosts output, good mixing—especially with pitched blade agitators—is key to getting everything evenly blended before separating starts.

Characteristics and Design Features of Pitched Blade Agitators

Pitched blade agitators create a flow that moves up and down. This helps mix thick liquids or keep solids spread out evenly in a liquid. It’s just right for getting things ready before filtering.

Synergy Between Agitators and Vacuum Belt Filters

Even mixing from pitched blade agitators leads to a steady solid layer on vacuum belts. This teamwork speeds up water removal and lowers the chance of clogs in the filter. It improves both how fast things move and how long the tools last.

Applications in Viscous or Heterogeneous Mixtures

Industries dealing with sticky stuff, like plastics or waste sludge, gain a lot from this combo. The agitator mixes everything properly, while vacuum belt filters pull out solids no matter the size or weight differences of the bits.

Industry Applications Benefiting from This Integration

Many areas have started using this combined method to make work easier while sticking to high quality rules.

Pharmaceutical and Fine Chemicals Production

Exact mixing along with trusty solid-liquid separation ensures the purity needed by groups like the FDA or EMA. The closed design also fits well in cleanroom spaces.

Petrochemical and Polymer Processing

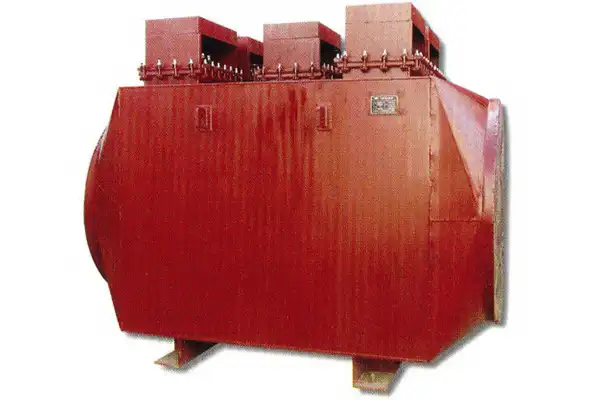

Thick resins need deep mixing before water is taken out. The horizontal rubber belt vacuum filter, built from new ideas, is a fresh kind of high-output solid-liquid separation. It’s great for reactions in plastic making, followed by getting solvents back.

Water Treatment and Environmental Solutions

From drying out sludge to cleaning smoke in power plants, these systems are widely used in metal work and eco-friendly tasks. They offer green answers that match worldwide eco rules.

Brief Introduction to NHD as a Reliable Equipment Supplier

NHD is a dependable maker, giving full solutions made to fit industrial needs all over the world.

Overview of NHD’s Product Series:

Filter Series & Automatic Press Filter Series

These cover rotary table filters, used in areas like phosphoric acid ore washing. They run steadily with improved designs, such as cone-shaped rollers or curved press strips that cut down on buildup.

Agitator & Thickener Series

Strongly built mixers, including pitched blade kinds, are made for even slurry mixing across different thicknesses.

Equipment for Sulfuric Acid Industry & Pressure Vessel Series

Custom-made, pressure-safe containers work in harsh settings common in acid-making plants.

Desulfurization Equipment Series & Filter Cloth Series

Special parts built just for smoke-cleaning systems using gypsum scrubbing methods.

Material Series for Industrial Applications

Includes tough alloys (316L/2205/2507) used in NHD’s tools, ensuring they last in extreme work conditions.

FAQs:

Q1: What makes vacuum belt filters more efficient than traditional filters?

A: Vacuum belt filters keep running without stops for hand-cleaning or clearing solids. They remove all the solid layer without needing strong water sprays. This cuts water use and greatly speeds up output compared to old ways like rotary drum filters.

Q2: Can pitched blade agitators handle high-viscosity materials?

A: Yes, they can. Pitched blade agitators make a powerful up-and-down flow, perfect for keeping solids spread out in thick liquids. They work well for things like plastic mixes or heavy slurries in mining or water cleaning.

Q3: How does NHD ensure long-term reliability in their equipment?

A: NHD adds features like heat-keeping vacuum boxes to lower buildup, sturdy flexible frames for easy fixes, and better drain slots for improved liquid flow. With over 20 years of know-how and more than 650 setups worldwide, their builds focus on lasting through tough industrial challenges.