Industrial solid-liquid separation operations depend on mechanical filter presses as their fundamental equipment. The systems have gained widespread use because they provide efficient operation with low power requirements and work well in different industrial settings including wastewater treatment and chemical processing and mining operations. The recessed chamber filter press represents a leading type of filter press because of its sophisticated design and operational benefits.

Overview of Mechanical Filter Press Technology

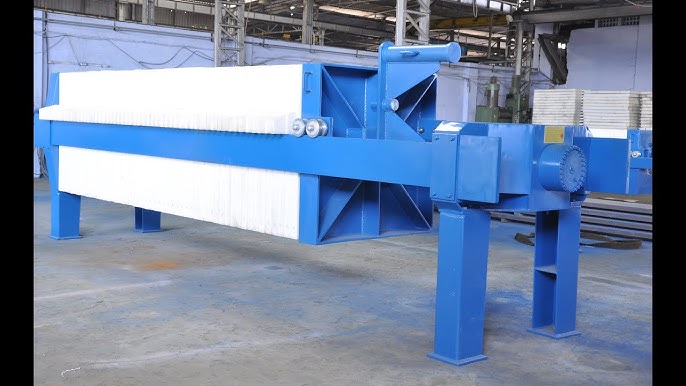

Mechanical filter press separates solids from liquids using pressure. It creates dry filter cakes for efficient processing. Widely used in mining and chemical industries.

What is a Mechanical Filter Press

A mechanical filter press operates as a batch-operated device which separates solids from liquids through pressure filtration. The device contains multiple plates which have filter cloths attached to them to capture solid particles while letting liquid pass through. The systems find broad application because they offer easy operation and affordable prices and support large slurry processing volumes.

Core Components and Their Functions

The system consists of filter plates (recessed or plate-and-frame) and hydraulic system and frame structure and feed pump and filtration cloths. The system depends on each component to function properly because plates create cake formation spaces and the hydraulic system operates the plates and the filtration cloths act as the filtering material.

How the Filtration Process Works

The filtration process starts when slurry enters the press system. The press operation uses pressure to push liquid through the cloths which results in solid accumulation that forms a cake. The press operates until chamber capacity reaches full then it opens to release the formed cakes for additional handling or waste management.

Recessed Chamber Filter Press Design and Operation

The operation of recessed chamber systems becomes clear when analyzing their distinct architectural design compared to conventional systems.

Structure and Configuration of Recessed Chamber Plates

The recessed chamber press serves multiple industries which include industrial and municipal wastewater treatment and chemical processing for efficient solid/liquid separation operations. The plates contain molded recesses which form separate chambers when they are clamped together. The design eliminates the requirement for separate frames which were present in traditional plate-and-frame models.

Working Principles in Solid-Liquid Separation

The slurry enters the press through the feed point which is located at the center of the plate during filtration. The filter cloths inside each chamber collect solids while the filtrate moves through corner ports into a manifold system. The increasing pressure from continuous feeding causes more solids to accumulate until the cakes reach their maximum thickness.

Advantages of Using Recessed Chamber Systems

The chamber filter press achieves its main advantage through its plate design which enables large center hole feeding instead of small openings located in the plate corners. The design enables quick filling operations while minimizing the chance of clogging. The recessed chamber design enables these filters to operate at higher feed pressures. The filter design provides simple cake discharge operations and low leakage rates because it uses gasketed or latex-edged plates.

Types of Filter Plates Used in Mechanical Filter Presses

The selection of appropriate filter plates determines both operational effectiveness and equipment durability.

Recessed Plates vs. Plate and Frame Designs

Traditional plate-and-frame designs create chambers by placing separate frames between plates. The modern filter press design employs plates with recesses which makes it known as a recessed chamber filter press. The design provides better sealing performance and easier assembly operations.

Materials Used for Filter Plates

The production of filter plates requires different materials which match particular operational needs.

Polypropylene Plates

These materials are lightweight and corrosion-resistant and suitable for chemical applications and hygiene-critical areas. The flexible nature of these materials enables them to handle multiple mechanical stresses without developing cracks.

Cast Iron and Stainless Steel Plates

The material selection depends on the need for enhanced mechanical strength and temperature tolerance. Cast iron performs heavy-duty operations yet stainless steel provides superior corrosion protection which makes it suitable for handling aggressive slurries and food-grade applications.

Key Performance Factors Influencing Efficiency

The operational efficiency of a mechanical filter press depends on multiple factors.

Filtration Pressure and Cycle Time Optimization

Higher pressures create dry cakes but they need stronger equipment to operate. The optimization of cycle time between production speed and cake quality determines how long the process should last because faster cycles produce wetter cakes.

Slurry Feed Characteristics and Their Impact

The speed of chamber filling and cake formation depends on three main factors which include viscosity and particle size distribution and solid concentration. The performance of all chambers remains consistent when using a uniform slurry.

Cake Discharge Mechanisms and Their Role in Productivity

The process of cake removal becomes more efficient which shortens the time needed for production cycle restarts. The equipment filtration area measures 168㎡ at its maximum and the unloading process takes between 30-40 seconds. The use of vibrating plates and automatic shakers in the process reduces manual work while keeping production levels steady.

Automation in Modern Mechanical Filter Press Systems

The introduction of automation through technological progress has brought about systems which improve operational safety and performance.

Automatic Plate Shifters and Cloth Washers

The automated plate shifters eliminate the need for human operators to perform discharge phase tasks. The system performs alternating front and back filter cloth washing operations while using its self-cleaning mechanism for efficient regeneration. The systems maintain cloth cleanliness while operating continuously.

Integration with PLC Controls for Operational Efficiency

PLCs enable users to set exact control parameters for cycle time and pressure settings and washing intervals which can be adjusted according to material types or production objectives.

Maintenance Considerations for Long-Term Operation

Regular inspection routines serve as the foundation for achieving optimal performance.

Routine Inspection and Cleaning Practices

The inspection process for operators includes checking seal wear and hydraulic system leaks and pressure drops and verifying cloth integrity after each cycle and performing scheduled cleaning operations with approved methods.

Common Issues and Troubleshooting Techniques

The system experiences three main issues which include gasket leaks that need replacement or realignment and feed pump problems that cause slow filling and improper cake formation due to incorrect slurry consistency. PLC systems with sensor feedback loops enable early detection of problems through automation.

Industrial Applications of Mechanical Filter Presses

Mechanical filter presses operate in multiple industries because they can adapt to various applications.

Usage in Mining and Metallurgy Industries

The equipment efficiently removes water from mineral concentrates and tailings which decreases waste volume before disposal or additional refining operations.

Role in Chemical Processing Plants

The production lines use polypropylene plates as chemically resistant materials to handle corrosive slurries while maintaining purity standards throughout operations.

Application in Wastewater Treatment Facilities

The mechanical presses function best for sludge water extraction before incineration or landfill disposal because they minimize volume while producing clean water for plant recycling.

NHD: Trusted Supplier of Industrial Filtration Solutions

The company operates as a major Chinese manufacturer of this technology since 2005 and has delivered more than 200 units worldwide. NHD has dedicated research and development since 2005 to create industry-specific solutions for customers.

Overview of NHD’s Product Series Offerings

NHD offers mechanical filter presses as part of its filtration technology portfolio which includes multiple options.

Filter Series and Automatic Press Filter Series

The vertical automatic models operate at high pressure levels of up to 16 kg/cm² to achieve fast unloading cycles. The maximum pressure level of 16 kg is suitable for applications that require low moisture content after filtration.

Agitator & Thickener Series, Pressure Vessel Series

The equipment functions to stabilize slurry flow rates before filtration stages while enhancing process control in subsequent operations.

Equipment for Sulfuric Acid Industry, Desulfurization Equipment Series

The production of sulfuric acid requires units made from corrosion-resistant alloys that engineers design for such harsh chemical environments.

Filter Cloth Series, Material Series

The production of high-performance panos follows particle size retention requirements which support operations in food-grade facilities and heavy metal recovery facilities.

Conclusion

Mechanical filter presses, like NHD’s, excel in solid-liquid separation with efficient recessed chamber designs, automation, and durable materials, delivering low-moisture filter cakes and boosting productivity across mining, chemical, and wastewater industries.

FAQs:

Q1: What is the primary benefit of using a recessed chamber filter press as a filtration system?

A: The main advantage of recessed chamber filter presses is their plate structure, which allows larger center hole feeding compared to traditional corner openings. This design enables faster filling, reduces clogging, and supports higher feed pressures for improved dewatering performance across various industrial applications.

Q2: What is the replacement schedule for filter cloths in mechanical filter presses?

A: The replacement schedule for filter cloths depends on usage frequency and slurry abrasiveness, typically ranging from several months to over a year. Automated cleaning systems extend cloth lifespan by preventing clogging and residue damage through alternating front and back washing.

Q3: Can mechanical filter presses effectively handle corrosive materials?

A: Yes, mechanical filter presses can handle corrosive materials effectively. Using polypropylene or stainless steel plates with chemically resistant frame coatings, they offer robust protection against acids and alkalis, making them suitable for chemical manufacturing settings.