The pulse of the Earth’s resources beats deep in the mines. Every mining and mineral processing is accompanied by the birth of a huge amount of slurry, which is the carrier of wealth, and a heavy burden. Traditional dehydration methods are stretched to the limit in terms of efficiency, cost and increasingly stringent environmental regulations. Mine is in urgent need of a “dehydration revolution”! The core engine of this revolution is the modern fully automatic filter press that combines the advantages of high pressure, intelligence and continuous operation. It is efficiently converting slurry into high-value concentrate and safe and controllable solids, reshaping the future of sustainable development in the mining industry.

Why Can’t Mining Operations Ignore Filtration?

The First Step to Increase Value: Concentration of Concentrate

After crushing, grinding, flotation and other processes, the final product of the ore dressing plant is a concentrate slurry. It contains high-grade target minerals (such as copper, gold, iron and lithium), but also contains a lot of water. If these slurries with extremely high water content are transported, the cost will be frighteningly high! Smelters also do not welcome wet raw materials. Mining water filtration is the first step to increasing value. Every 1% reduction in water content can significantly reduce transportation and smelting costs.

The Hidden Challenge: Energy and Efficiency Trade-Off

In the mining and industrial sectors, tailings deep dewatering treatment remains a critical link in the production chain, but traditional management methods often face a dilemma: pursue lower energy consumption or higher slurry dewatering efficiency?

To save short-term energy costs, many companies tend to use low-power or outdated filtration equipment, resulting in incomplete tailings dewatering and high moisture content. This not only increases the burden of tailings transportation and storage, but also can lead to higher environmental compliance costs due to leakage and secondary contamination. Furthermore, problems such as mud cake rewetting and equipment blockages lead to frequent downtime for maintenance, further increasing maintenance costs and production losses. Modern automatic filter presses, by combining intelligent control with high-efficiency filtration technology, strike the optimal balance between energy consumption and efficiency.

Evolution and Rise of Filter Presses

Early plate filter presses required manual disassembly and cleaning of filter cloths piece by piece, which was labor-intensive, inefficient, and performed in harsh conditions. Although centrifuges can run continuously, they are not effective in dehydrating fine particles, and have high energy consumption and maintenance costs. Therefore, fully automatic vertical pressure filters stand out with their unique advantages:

High-Pressure Filtration: It can apply pressure far higher than traditional methods, squeeze the filter cake like a “juicer”, and obtain extremely low moisture content. Taking phosphogypsum as an example, the moisture content of its filter cake can be as low as 10%, potentially even eliminating the need for the traditional drying process.

Strong Ability to Handle Particles: The slurry dewatering effect of fine-grained materials (such as clay and ultrafine tailings) is significantly better than that of centrifuges.

Clear Filtrate: The separated filtrate (water) has high clarity and can be directly reused in the production process to achieve water resource recycling.

However, the early automatic mining filter presses still had their weak spots. Single-unit processing capacity was limited, so big jobs needed multiple machines. Automation wasn’t all the way there either—operators still had to keep a close eye on things. Filter cloth upkeep was heavy work, and the machines weren’t exactly thrifty with power.

Battle of Technologies: Vertical vs. Plate vs. Diaphragm

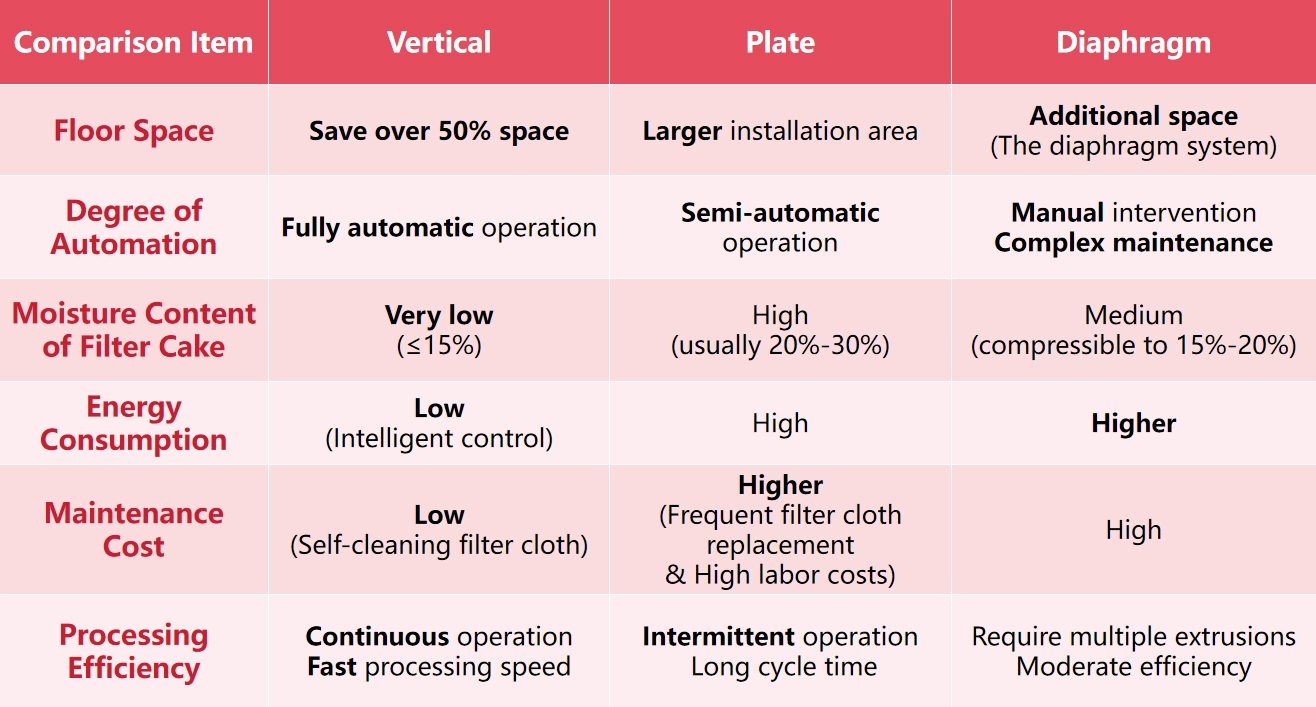

Modern mining filter presses come in many varieties, primarily vertical, plate, and diaphragm. Vertical filter presses are suitable for high-demand, continuous production operations, such as mining tailings deep dewatering and chemical sludge treatment. Plate filter presses are ideal for small-batch, high-variety production on a low budget. Diaphragm filter presses are suitable for industries that require high filter cake moisture content but can tolerate high energy consumption. You can choose the right filter press based on your production needs.

Of course, the filtration equipment model you choose will directly impact production efficiency, operating costs, and environmental compliance. With its innovative design, vertical filter presses significantly outperform traditional plate and diaphragm filter presses in terms of floor space, degree of automation, filter cake moisture content, energy consumption, and maintenance costs. From the table below, you can intuitively understand the advantages and disadvantages of these three types of mining filter presses.

NHD’s Automatic Vertical Filter Press — A New Benchmark in Dehydration

NHD fully recognizes the critical demand of the mining industry for efficient, reliable and intelligent dehydration, and has devoted all its efforts to the development of the automatic vertical pressure filters since 2005.

NHD’s fully automatic vertical pressure filters integrate advanced domestic and international filter press technologies and are widely used in solid-liquid separation, washing, filtration, and dehydration processes in industries such as nonferrous metals, mining, smelting, chemicals, coal preparation, ceramics, papermaking, dyes, and wastewater treatment. NHD automatic vertical pressure filters, with over 200 units sold and successfully commissioned worldwide, have earned widespread acclaim for their exceptional performance in production capacity, filter cake moisture control, automation level, and structural design.

Конкурентные преимущества:

Automation and Efficiency: The system operates fully automatically via a control panel, equipped with self-diagnostic and automatic alarm functions. The processing capacity has been significantly improved, enabling the mine to maximize its production capacity.

High Production Capacity: All six working processes operate automatically and continuously, delivering over 6 times the production capacity per unit area compared to frame filter presses.

Self-Cleaning Filter Cloth: The filter cloth features alternating washing on both surfaces with excellent cleaning results. Its horizontal placement ensures uniform cake thickness up to 45mm.

Low Moisture Content in Filter Cake: With maximum extrusion pressure reaching 1.6MPa, the cake moisture content can be reduced below 10% under specific conditions, potentially eliminating conventional drying processes. This ensures stable, ultra-dry filter cakes for both concentrates and tailings, minimizing downstream handling costs.

Compact Structure Saves Space: The filter-column vertical design requires minimal floor space, enabling facility upgrades with reduced or zero additional plant investment.

Green and Энnvironmental Protection: Through energy-saving technology, unit energy consumption is reduced, and deep slurry dewatering directly contributes to the green and sustainable development goals of the mine.

Currently, NHD has established long-term cooperative relationships with many outstanding international partners. A notable example is the world’s 180m2 vertical automatic filter press provided by NHD is used for a wet-process nickel-cobalt smelting project in Papua New Guinea. In addition, NHD has provided 13 sets of 180m2 and 168m2 vertical automatic filter presses and 5 sets of 168m2 ones for the wet nickel-cobalt smelting projects in Indonesia Huayue and Ningbo Liqin Mining respectively.

Conclusion

As mineral resources get harder to come by and environmental rules tighten worldwide, mining water filtration has had to step up. Nowadays, intelligent upgrades are shaking up the whole industry. What used to be just solid-liquid separation has turned into a key part of operations—helping teams work more efficiently, stay safer, cut costs, and keep things sustainable. Choosing a fully automatic filter press that represents the top level of the industry is choosing a more efficient, reliable, and sustainable future for the mine.

NHD’s Automatic Vertical Пressure Filter, with innovative technology as its engine, is committed to becoming a trusted “dehydration partner” for global mining enterprises. Together, we can pioneer a new era of efficient and eco-friendly mineral processing! If you want to get more information about filtration equipment, please contact our experts at [email protected].