In a world pushing toward carbon neutrality and the smart shifts of Industry 4.0, industries like mining and chemicals face tough demands. Old-school filter presses gulp down too much energy. They need workers hovering over them all day. And they rarely hit the mark on strict green rules. The automatic vertical pressure filter addresses these challenges head-on. This intelligent chemical filtration equipment integrates PLC automation, operates at pressures up to 1.6MPa, and features self-cleaning technology for minimal maintenance. NHD has rolled out more than 200 of these units around the globe since 2005. We’ve changed how mining filter presses work, making things smoother in tough spots like ore processing and chemical plants. If you’re in mining or chemicals, this technology could reshape your daily grind, cutting waste and boosting output.

How Intelligent Technology Reduces Costs

Mining and chemical operations often battle rising costs from labor, energy, and downtime. Traditional setups drain resources with constant manual tweaks and extra steps. But intelligent chemical filtration through automatic vertical pressure filters flips the script. These systems automate the heavy lifting, slashing expenses in ways that add up fast. Let’s break it down.

Full Automation, Reduced Labor

Gone are the days of teams babysitting machines. An automatic filter press runs on its own, guided by smart controls. This means fewer hands on deck.

In a traditional standard setup, you’d need 3-4 operators per shift just to keep things moving. With an automatic vertical pressure filter, that drops to about 0.5 operators—mostly for quick checks. That’s a 75-85% cut in labor hours. For a mid-sized mining site handling 500 tons of slurry daily, this could save $150,000 a year in wages alone. Workers shift to higher-value tasks, like planning or quality checks. It’s not just about saving money; it’s about smarter work. Operations utilizing vertical pressure filters demonstrate consistent performance with reduced human error compared to manual systems.

Elimination of Secondary Drying

Traditional filtration processes require secondary drying equipment and substantial energy input. Intelligent chemical filtration achieves filter cake moisture content below 10%, with mining applications frequently reaching 6-8%. No more rotary dryers or flash dryers eating up space and power. A typical chemical plant might burn 20-30% less electricity without them. For instance, in phosphate processing, skipping secondary drying cuts energy use by 15 kWh per ton of product. That’s real savings—up to $50,000 annually for a facility producing 100,000 tons. The cake comes out ready for transport or further use, streamlining the whole line.

Self-Cleaning Technology & Maximum Uptime

Equipment downtime directly impacts profitability in continuous processing operations. Self-cleaning technology in mining filter presses maintains operation without manual cleaning interruptions. These systems blast away buildup automatically, hitting 98% uptime in field tests, compared to traditional filters that typically operate at 80% uptime due to fouling-related stoppages. In a chemical filtration equipment setup, this means processing 20% more material per day. NHD vertical pressure filters have demonstrated continuous operation exceeding 5,000 hours in specific installations, delivering consistent production throughput.

Achieving Compliance & Sustainability Goals

As environmental regulations become increasingly stringent regarding emissions and waste management, industrial operations must adapt rapidly. Automatic vertical pressure filters offer a path forward, blending efficiency with green practices. They help meet standards while cutting environmental footprints. This isn’t just compliance—it’s a step toward long-term sustainability objectives.

- Ultra-Low Moisture Content = Waste Reduction

Wet waste is a headache for mining and chemicals. It presents significant challenges, including increased storage requirements, elevated handling costs, and potential environmental hazards. With vertical pressure filters, moisture drops below 10%, turning slurry into compact cakes. This cuts waste volume by 40-50%. A mining operation dealing with tailings might reduce landfill needs by 30,000 cubic meters yearly. Less waste means lower disposal fees—around $100 per ton saved in some regions. Sustainable chemical filtration like this contributes to improved site management and facilitates regulatory compliance.

Beyond quantifiable benefits, this technology promotes resource optimization and supports continuous improvement in waste management practices.

- Efficient Water Recycling and Reuse

Water is gold in dry mining areas or water-scarce chemical plants. Traditional filters waste it through poor recovery. Intelligent systems recycle up to 95% of process water. In a setup with an automatic filter press, that’s 200,000 liters saved per day for a large operation. Filters capture and clean filtrate for reuse, slashing fresh water intake by 60%. Chemical filtration equipment from NHD has helped plants in arid zones cut water bills by $80,000 annually. It’s practical sustainability.

This recycling builds resilience. Operations become less vulnerable to water shortages, supporting long-term planning in volatile environments.

- A Cleaner, Safer Working Environment

Dust and spills from old filters create hazards. Workers face slips, fumes, and heavy lifts. Automatic vertical pressure filters enclose the process, reducing exposure. Air quality improves by 70% in monitored sites, with fewer particulates. Safety incident rates decrease significantly, with NHD installations reporting up to 40% reduction in workplace accidents.

The Intelligent Core of NHD Vertical Pressure Filters

At the heart of these advancements lies smart engineering. NHD’s automatic vertical pressure filter integrates controls, sensors, and automation for seamless runs. This core drives the transformation in the mining and chemical fields.

The Brain: Advanced PLC Control System

Every smart machine needs a strong command center. NHD uses a Siemens PLC platform for reliability. The touchscreen interface offers multi-language support, making it user-friendly worldwide. It can store recipes for various slurries—like acidic chemicals or mineral ores—allowing quick switches. Operators adjust parameters with a few taps, handling pressures up to 1.6MPa.

The Senses: Self-Diagnosis and Alarm System

Early issue detection in automated systems prevents major equipment failures. NHD’s system monitors in real time. Sensors track pressure, flow, and temperature, flagging anomalies instantly. Intelligent fault detection predicts wear, like diaphragm fatigue, before failure. Predictive maintenance capabilities reduce unplanned downtime by up to 50%. Alarm notifications are transmitted directly to the control room operating system, ensuring immediate operator awareness.

The Action: Automated Cycle from Start to Finish

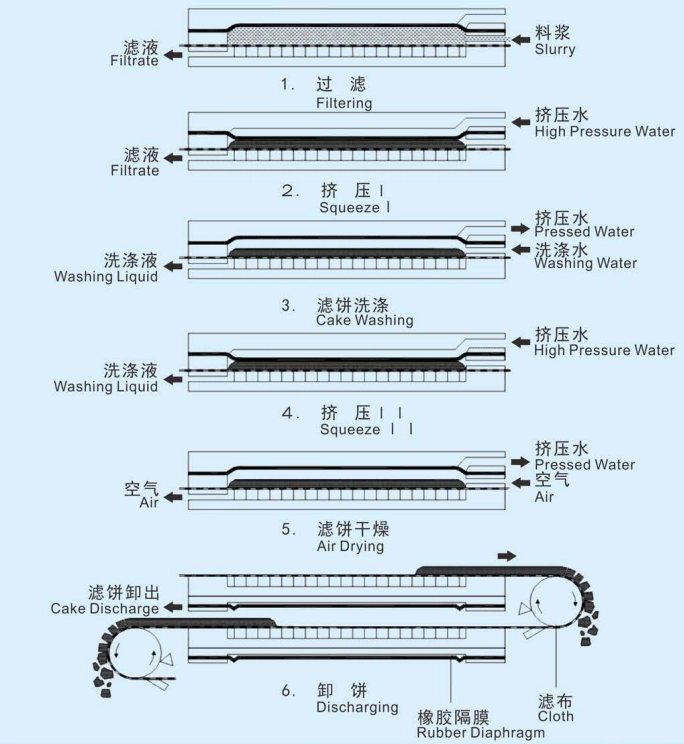

The real magic happens in the cycle. NHD’s automatic vertical pressure filter follows a precise six-step process, all hands-free. This cycle, powered by intelligent chemical filtration, handles 10-20 tons per hour in mining setups. It’s efficient and repeatable.

- Filtering: The frame closes, and slurry flows through the feed pipe into each chamber. The filtrate penetrates the cloth into the chamber, then passes through the flexible tube before discharge via the header.

- Squeeze I: High-pressure water pumps through the flexible pipe to the top of the diaphragm, applying squeezing pressure. This forms the filter cake between the diaphragm and cloth while expelling

- Washing (Optional): If needed, slurry gets pumped into the filter chamber through the same manifold pipe used for slurry. As the chamber fills completely with wash liquid, the diaphragm lifts to expel high-pressure water above it. The wash liquid then flows through the filter cake and cloth before exiting via the discharge pipe.

- Squeeze II (Optional): This step follows if washing isperformed. Remaining wash liquid in the chamber is expelled using the same compression method as Squeeze I.

- Сушилка воздуха: Compressed air is introduced into the filter chamber through the manifold pipe, filling the chamber and raising the diaphragm before being discharged. The air passing through the cake reduces the moisture content to the optimal level and also empties the filtrate chamber.

- Cake Discharge: After the drying process is complete, the frame assemblies open, and the cloth drive units start operating. The filter cake on the cloth is then discharged from both ends of the filter.

Comprehensive ROI Analysis: Why NHD Vertical Filters Pay for Themselves

Investing in new tech demands clear returns. NHD’s vertical pressure filters deliver through savings and risk cuts. Let’s look at the numbers.

- Cost Optimization: Labor, Maintenance & Space

While significantly reducing labor costs, the self-cleaning function also lowers maintenance costs by 60%, reducing weekly overhauls to monthly inspections. Space savings are equally significant—the compact design occupies only half the floor space of traditional equipment. A full analysis: For a chemical plant, the initial cost of $500,000 pays back in 2-3 years. Annual savings: $200,000 in labor, $100,000 in energy, $50,000 in maintenance. Total ROI hits 40% in year one.

- Risk Reduction and Compliance

Environmental non-compliance penalties can reach $100,000 per violation. NHD filters ensure ultra-low emissions and waste output, dodging penalties. Improved operational safety contributes to insurance premium reductions of 15-20%. Predictive maintenance technology prevents equipment failures, avoiding approximately $30,000 in annual emergency repair costs.

Вывод

In today’s world, efficiency and sustainability are no longer optional but central to maintaining a competitive edge. The NHD Automatic Smart Vertical Pressure Filter is more than just a piece of equipment; it’s an integrated solution that combines intelligent decision-making, resource optimization, and sustainable practices. By embracing such smart technology, factories can not only significantly reduce operational costs and comply with environmental regulations with ease but also build a more resilient and future-proof modern enterprise.

Ready to explore the smart filtration solution tailored for you? Visit the NHD official website or contact us at [email protected] to schedule a free consultation with our experts and discover how much efficiency and carbon reduction your plant can achieve.