Alumina (Al2O3) is often called the “tooth of industry.” It’s everywhere. High-purity alumina goes into sapphire glass for smartphone screens. The same material forms the base for the phosphors in LED lights. In the bathroom, it’s hiding in the glossy glaze on premium ceramic fixtures. In the lab, it turns up again—this time as an adsorbent in vaccine production. One material, countless roles.

Challenges of Alumina Production

Every year, the world produces over 130 million tons of alumina. More than 90% comes from the Bayer process. In this process, one step makes or breaks efficiency and cost: separating solid aluminum hydroxide from slurry—the dehydration stage. It’s not a small drain on resources. The alumina industry uses more than 300 billion kWh of electricity a year, and dehydration alone eats up about 15% of that. Traditional filtration gear—like plate-and-frame presses or belt filters—runs into some stubborn problems:

- Efficiency bottleneck

- Stop-and-go operation: Old-school filters need frequent shutdowns to wash the filter cloth. That breaks the flow of production.

- Thick slurry troubles: Aluminum hydroxide slurry is sticky stuff. It clogs cloths, slows filtration, and generally refuses to behave.

- High Energy Use & High Cost

- Pumps and heat: Relying on high-pressure pumps or thermal drying leaves the filter cake too wet (over 25% moisture), which means more energy burned in roasting.

- Maintenance headaches: Clothes wear out fast. Cleaning is labor-heavy. Downtime adds up.

- Environmental &Quality Concerns

- Wastewater issues: Wash water is alkaline. If it’s not treated right, it can cause real environmental damage.

- Unstable product quality: When moisture in the filter cake jumps around, so does the purity of the alumina.

The industry is looking hard for a fix—something that runs continuously, cuts energy use, and keeps things moving. One answer on the table: the rotary pan vacuum filter. Its new design is starting to change the game.

Why the Pan Vacuum Filter Is a Game Changer?

The Rotary Pan Vacuum Filter, with its unique design, is an ideal choice for alumina dehydration. Its high efficiency is demonstrated in the following aspects:

- Continuous Automated Operation: The rotary vacuum filter pan, combined with vacuum suction, continuously feeds slurry, removes filtrate, and automatically removes filter cake without downtime, increasing production capacity by 30%-50%. It features a self-cleaning system and is equipped with a high-pressure water or compressed air backflush device to reduce filter cloth clogging.

- Significant Energy Saving &Consumption Reduction: Compared to filter presses, energy consumption is reduced by 20%-40%, achieving low vacuum energy consumption. The filter cake moisture content is stably controlled at 15%-18%, reducing gas consumption during the roasting stage.

- Adaptability to Complex Operating Conditions: The speed of the rotating vacuum filter pan can be adjusted. That means the filtration cycle can be fine-tuned to match different aluminum hydroxide slurry concentrations. As for the pan itself, it’s built from materials like PP or stainless steel—both tough against acid and alkali corrosion. This keeps the equipment running longer and saves on replacement costs.

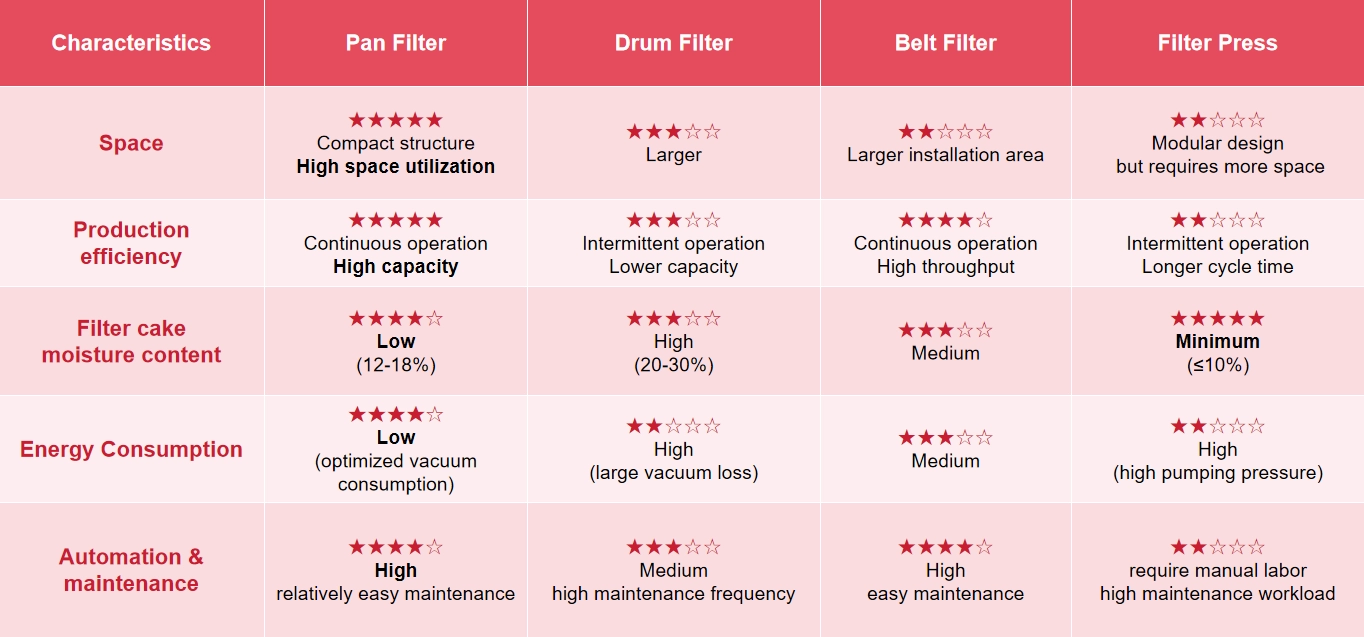

- Comparison of Filters in Alumina Production:

How to Choose High-Quality Pan Vacuum Filter?

There are many types of rotary vacuum filtration on the market, and the quality is also uneven. If you want to choose the right pan vacuum filter, you should focus on the following indicators:

- Core Performance Parameters: In many plants, 100–200m2 is pretty typical. You need to choose a filtration area that fits your production scale. The vacuum level also matters a lot; most operators stick to around -0.04 to -0.06 MPa, a range that pulls water out fast while keeping filtration stable. Then there’s the filter cake. Reliable equipment keeps its moisture at a steady level, usually under 18%. That small detail makes a big difference, because it keeps downstream processing running much more smoothly.

- Malzeme &Structure: The rotary vacuum filtration pan should be made of 316L stainless steel or reinforced polypropylene (PP), which are corrosion-resistant and lightweight. Equally critical is the filter cloth—it should be non-clogging and easy to clean, such as monofilament filter cloth.

- Manufacturer Service Capabilities: Beyond technical specifications, the manufacturer’s support capabilities are crucial for long-term operation. Prioritize suppliers with a proven track record in the alumina industry and comprehensive after-sales support, including reliable spare parts supply and rapid response services. Take NHD as an example. NHD stands as a leading provider of filtration solutions for the alumina industry, serving a portfolio of over 200 global partners. Following its participation in the Lam Dong alumina project constructed by CHALIECO for Vietnam’s Vinacomi Group, NHD has once again successfully provided a 100m2 pan vacuum filter for the 650,000 tons/year alumina project of Nhan Co.

Advantages of NHD’s Pan Vacuum Filter for Alumina

In fact, throughout the development of the alumina industry, production scale was long constrained by technical bottlenecks in key equipment. Around 2007, global alumina production capacity per line was capped at just 400,000 tons annually. This was primarily due to aluminum hydroxide filtration equipment. At the time, only Dorr-Oliver of Germany could provide large-scale pan filters, yet even their largest models offered a maximum filtration area of only 62m2, which proved insufficient to support any further scaling of production.

Against this backdrop, NHD achieved a significant breakthrough through its independent R&D capabilities. In 2008, a team led by former Chairman Chen Changlin developed a “Method for Machining Large-Diameter Annular Discs”—awarded the Outstanding Chinese Patent Award—which successfully overcame the manufacturing challenges associated with large pan filters. With this innovation, NHD not only broke the international technology monopoly, it also introduced the industry’s first 80m2 aluminum hydroxide pan vacuum filter, elevating the entire industry to a new level of technological capability.

Since then, NHD has consistently been committed to innovation and iteration in filtration equipment. In recent years, the company has provided ultra-large pan vacuum filter solutions to numerous large enterprises. In 2024, the company successfully developed a world-leading 260m2 pan filter system, further solidifying its leading position in the field. Today, NHD has become a technology leader in the global alumina equipment industry, continuously providing customers with high-performance, high-reliability filtration systems, and helping the global alumina industry achieve leapfrog development.

There are now totally more than 250 sets of installed applications at home and abroad. In addition, the pan vacuum filter has been promoted and used gradually in other areas such as metallurgy, environmental protection, ore washing and paper making etc. With the experiences and optimized design, the pan vacuum filter now has a lot of technical features and advantages:

- Increase Alumina Production Capacity: In 2008, NHD’s first 80m2pan vacuum filter successfully increased annual production capacity to 500,000 tons per line, surpassing the global record of 400,000 tons at the time. Subsequently, the company’s equipment scale continued to expand, and by 2024, the 220m2 pan filter manufactured for Hebei Wenfeng Industry was capable of supporting an annual production capacity of 1.6 million tons per line. Currently, NHD manufactures a world-leading 260m2 pan filter and is capable of designing alumina production lines with an annual output of 2 million tons for customers, continuing to lead the global upgrade of single-line alumina production capacity.

- Stable Structure & Reliable Operation: The scientifically designed filter unit, equipped with tapered support rollers and a center positioning system, ensures even loading and smooth operation. Strict control of the entire plate flatness prevents uneven wear and vibration, extending the equipment’s service life.

- Strong Adaptability & Wide Application: Multiple design improvements enable it to process complex materials such as low-grade ore, expanding its application scope. Adjustable overflow distributors and washing devices ensure uniform distribution and efficient washing.

- Energy-Efficient & Easy Maintenance: The new flat nozzle design combines low energy consumption, high flushing power, and water conservation, and is even more effective when used with anti-clogging filters. The bottom-mounted, high-angle central distribution valve effectively eliminates scaling and blockage, reducing cleaning effort and increasing operational efficiency.

- Anti-clogging Design for Improved Efficiency: The curved rib structure significantly reduces scaling in the filter cloth trough, shortening filter cloth replacement time and extending service life. Optimized distribution and washing systems ensure uniform filter cake drying and significantly improve washing performance.

Conclusion

NHD is the industry benchmark for global industrial solid-liquid filtration systems, especially in the field of alumina filtration technology. Since its establishment, the company has been continuously innovating for more than 30 years and has gained a good reputation at home and abroad. As one of the leading rotary vacuum filter manufacturers, NHD continues to deliver high-performance, reliable solutions tailored to diverse industrial needs. In addition to filtration solutions, NHD also provides advanced metallurgical equipment to support the broader needs of the mining and metals industries.

Driven by innovative technology, NHD’s Rotary Pan Vacuum Filters are committed to becoming a trusted “dehydration partner” for global aluminum customers, jointly opening a new chapter in the efficient and green development of the alumina industry! If you would like to learn more about our rotary vacuum filtration equipment, please contact our experts at [email protected].