Filter presses are a big deal for industries splitting solids from liquids. Picking between manual and automated ones? Yeah, that’s a tough call. Both have their ups and downs—think costs, labor, output, and maintenance. This piece digs into how these machines do their thing, stacks them up against each other, and guides you to the best choice, whether you’re running a small shop or a huge production line.

Overview of Filter Press Technology

Filter presses are super important for splitting solids from liquids across all sorts of industries. They push a slurry—basically a soupy mix of liquid and solid stuff—through a filter under pressure. The liquid slips through, while the solids get left behind, piling up into a filter cake. That’s the core idea for both manual and automated filter presses. But, man, the way they work is pretty different!

Basic Principles of Solid-Liquid Separation

The core of a filter press is pressure filtration. Slurry enters chambers made of plates and frames covered with filter cloths. The liquid flows through the cloth, while solids stay behind, slowly building into a cake. During this process, slurry is pumped into the machine. Coarse solids get caught on the cloth’s surface, forming a cake, while fine liquid passes through and collects in a tube system.

Common Applications Across Industries

Filter presses are vital in fields like mining, food processing, petrochemicals, pharmaceuticals, ceramics, and wastewater treatment.Seriously, they’re just the thing for jobs that need to pull solids out fast or grab valuable materials back!

Key Components and Operational Mechanisms

Both manual and automated filter presses have filter plates, a hydraulic system, a feed pump, and drainage setups. Advanced models add air drying and cake washing to boost performance. The process includes:

Step 1 – Feed: Slurry enters the chamber.

Step 2 – Air Drying: Air flows quickly into the chamber to dry the cake.

Step 3 – Discharge: The frame opens to release the cake.

Manual Filter Press Systems

Manual systems remain common in smaller operations or where budgets are tight, but they have clear drawbacks.

Structure and Operation of Manual Filter Presses

A manual press needs workers to open and close plates and start each cycle. Feed pumps are often controlled by hand. This simple setup reduces upfront costs but limits the ability to handle large volumes.

Labor Requirements and Operational Complexity

Manual presses require constant human effort. Workers load and unload cakes, shift plates, clean cloths, and monitor pressure. This hands-on approach is time-consuming and can lead to mistakes.

Maintenance Considerations and Downtime Factors

Frequent manual handling wears out parts like hydraulic cylinders or seals. Mistakes or tired workers can cause unexpected downtime, hurting productivity.

Automated Filter Press Systems

Automation streamlines filtration, cutting down on human effort and boosting efficiency.

How Automated Filter Presses Work

Automated systems use PLC control to manage feed cycles, plate shifting, cake discharge, washing, air drying, and even cloth cleaning. Fully automatic operation ensures steady output without needing constant human input.

Labor Reduction and Operational Efficiency

Since machines handle most tasks, like flushing cloths after each cycle, automated presses need far less labor. This leads to smoother, more reliable production.

Consistency in Filtration Performance

Sensors precisely control pressure during feeding and dewatering. The maximum pressure of 16 kg creates a very dry filter cake, giving consistent results compared to manual systems.

Comparative Analysis: Manual vs. Automated Filter Presses

Choosing between manual and automated systems depends on weighing key factors tied to your goals.

Filtration Cycle Time and Throughput Efficiency

Automated presses speed up cycles with quick plate shifting and optimized feed and drying steps. Air flows rapidly into the chamber to dry the cake, allowing more output per day than manual systems.

Energy Consumption and Resource Optimization

Automated systems may use more power at first due to motors, but they save energy over time. They can skip drying ovens and use less water for cleaning, cutting costs. Sometimes, the drying step is not needed at all.

Safety, Ergonomics, and Operator Exposure

Automated presses keep processes inside sealed chambers, reducing contact with harmful materials. This makes them much safer than open-frame manual designs.

Cost-Benefit Evaluation Over the Equipment Lifecycle

Initial cost is only part of the picture. Long-term value matters more when picking filtration equipment.

Initial Capital Investment vs. Long-Term ROI

Manual filter presses are cheaper to buy at the start. But, boy, they need a lot of workers, which racks up costs over time. Automated systems? They cost more upfront, sure. Still, they save you cash in the long run. Less downtime, fewer folks needed, drier cakes that cut drying expenses, and gear that lasts longer because it’s all controlled nicely and steadily.

Maintenance Costs and Component Longevity Comparison

Automated presses come with self-cleaning tricks that make filter cloths last longer and cut down on upkeep. They scrub both sides of the cloth automatically. Keeps things running smoothly without constantly stopping to clean or swap out parts.

Integration With Digital Monitoring and Industry 4.0 Standards

Modern filtration goes beyond mechanics—it embraces digital equipment.

Data Logging, Remote Monitoring, and Predictive Maintenance

Advanced presses use PLCs with touch screens to track pressure, flow rates, and cake thickness in real time. They can even predict when maintenance is needed based on usage, ensuring stable operation without constant oversight.

Scalability for Future Expansion

As production needs grow, automated presses can be upgraded easily with modular additions. Manual systems, with fixed designs, struggle to scale without major changes.

Environmental Impact Considerations

Sustainability is a key factor in choosing equipment, and filter presses play a role here.

Sludge Handling Efficiency

Automated presses create drier cakes that are easier to handle, dispose of, or reuse. After the cake forms, it settles at the bottom and is removed in the next cycle, reducing environmental impact.

Reduction in Water Usage and Waste Generation

Self-cleaning features like backflushing use less water per cycle. This efficient cleaning lowers water waste, which is vital in areas with scarce water or strict waste rules.

Recommendations Based on Application Needs

The best system depends on your specific needs, not just your budget.

When to Choose a Manual Filter Press

Manual presses work for small, occasional batches or where labor is cheap, and automation’s benefits don’t yet outweigh costs. They suit non-critical tasks like pilot testing or small-scale waste treatment.

When to Choose an Automated Filter Press

For high-volume, continuous operations—like mining tailings dewatering or food-grade clarification—automated presses are a must. They ensure steady quality and efficiency at scale. Explore the available automatic press filter series here.

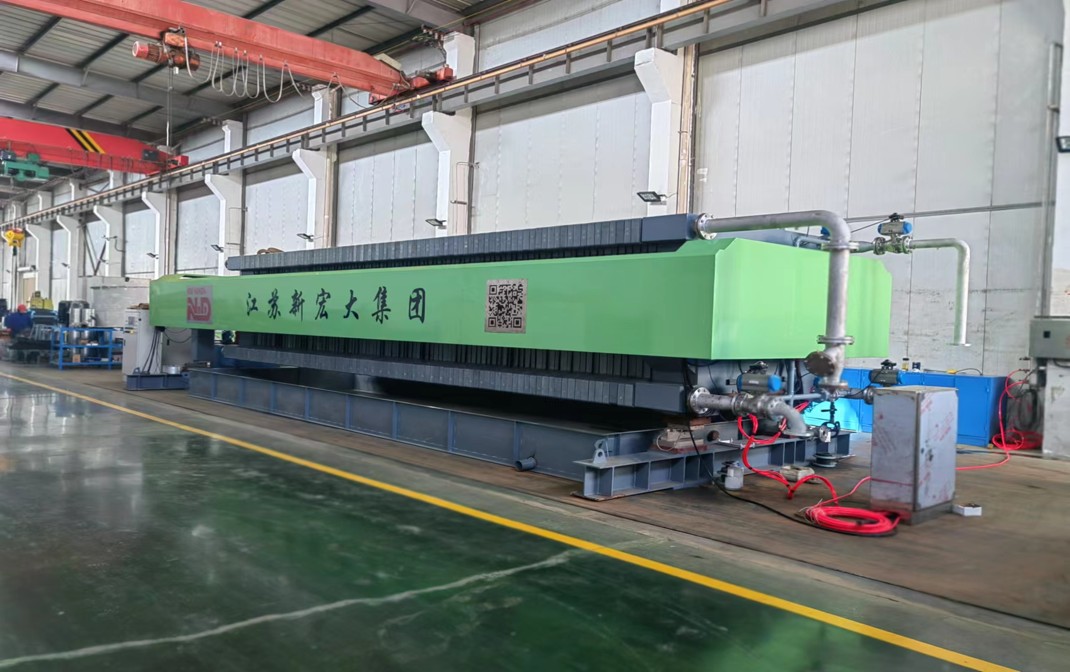

Why Choose NHD’s Automated Filter Press Solutions

If you need top-notch filtration for industries like chemical plants or wastewater facilities, NHD offers innovative solutions backed by expertise.

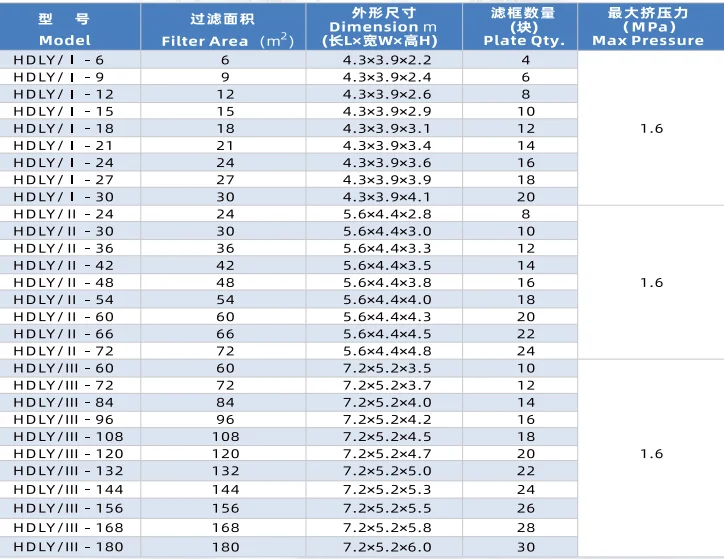

NHD’s automatic press filters shine with their vertical design, saving space while maximizing output through continuous cycles. The HDLY Vertical Automatic Pressure Filter, developed by New Hongda, separates solids from liquids through washing, filtering, and dewatering. Features like dual-side vulcanized rubber sealing plates prevent leaks, while a dynamic weighing system ensures precise feed control. The whole-machine weighing system supports automatic cycle work, delivering unmatched reliability in tough conditions.

Customization lets you adapt setups to your material needs, supported by testing with NHD’s 1.6m² pilot unit. Click here for detailed specs & configurations.

Final Considerations for Equipment Selection Strategy

Your equipment should match your production goals, both now and in the future. An automated system offers immediate efficiency gains and digital integration for predictive analytics later. Partnering with an experienced provider like NHD ensures support during setup and scaling, making it a long-term investment rather than a one-time buy.

FAQ

Q: What industries benefit most from automated filter presses?

A: Industries needing continuous operation and strict quality—like mining tailings, food-grade separation, or chemical manufacturing—gain the most. Automated presses cut downtime and ensure steady output.

Q: How does an automated system reduce operating costs over time?

A: Automation lowers labor needs and boosts energy efficiency. Steps like air drying eliminate heating stages, reducing utility and manpower costs over time.

Q: Can I upgrade my existing manual press system?

A: Some manual presses can add features like motorized plate shifters. However, full automation often requires new systems with PLC-based designs tailored to your process.