On smoggy or dusty days, the core mission of the masks we wear is to protect our health by blocking tiny particles that are invisible to the naked eye. These PM2.5 particles may be less than 2.5 microns in diameter, but they can have profound effects on our respiratory systems. Translating this scenario to chemical and mining production reveals a strikingly similar situation: reactors and slurry pools are also filled with a large number of “invisible” particles measuring only 1-5 microns. Although small, these particles are powerful enough to degrade the purity of the final product, poison catalysts, and otherwise pose a difficult environmental challenge.

Therefore, precision filtration is more than just a safety measure; it’s a crucial step in determining product quality and process efficiency. This is where automated leaf filters come in. In this article, we’ll explore how they work and why they’re crucial to your operations.

Address Low Solid Content and Ensure Product Purity

Handling slurries with low solid content is tricky in chemical processing and mining. These mixtures often look thin but hide particles that disrupt purity. Traditional methods fall short here, leading to inconsistent results. Automatic leaf filters change that by targeting those fine solids directly.

The Hidden Cost of Unfiltered Fine Particles

Tiny particles in process fluids might seem harmless. But they build up over time. In mining filtration, for example, unfiltered solids can contaminate downstream equipment, causing wear and breakdowns. One study from a phosphate plant showed that ignoring these fines led to a 15% drop in equipment lifespan. Costs skyrocket with repairs and lost production. In chemical production lines, the same problem takes another form. When impurities remain in process liquids, they can trigger unwanted reactions, contaminate catalysts, or even spoil entire batches of valuable products. As a professional leaf filter manufacturer, NHD designs its automatic leaf filter to remove ultra-fine impurities before they cause damage. It prevents the chain reaction of problems that starts with overlooked contaminants. Moving from costs to benefits, let’s see how precision changes the game.

Crystal-Clear Filtrate with Precision Filtration

Achieving a spotless filtrate is the ultimate goal of fine filtration systems—and few do it better than a vertical leaf filter. NHD’s advanced design uses layered cloths to trap even the smallest particles. Filtrate with purity levels above 99% in many cases. In the chemical industry, this translates into cleaner products ready for downstream use or direct sale—without extra polishing or re-processing steps. In mining operations, it means crystal-clear process liquids that can be safely recycled, reducing fresh water consumption by up to 20% and cutting overall operating costs. Built to withstand pressures of up to 1.0 MPa, NHD’s vertical leaf filter performs reliably under the most demanding process conditions. The result isn’t just clarity for its own sake—it’s the conversion of what was once waste into valuable, reusable resources that drive both sustainability and profitability.

From Waste to Value: Effective Solid Recovery

What happens to the captured solids? In an automatic leaf filter, they form a cake that’s easy to recover. Instead of discarding it, you reclaim valuable materials. For mining filtration, this could mean pulling out metals from tailings, boosting yield by 10-15%. Chemicals benefit too—recovered pigments or catalysts go back into production. NHD’s system automates the discharge, so no manual scraping. Solids settle in the cone bottom after back-flushing, ready for the next cycle. It’s a simple way to turn filtration from a cost center into a value driver.

Operate in a Fully Enclosed System for Safety and Stability

Open systems expose materials to air, heat loss, and leaks. In chemicals and mining, that spells trouble. NHD’s enclosed leaf filter design solves these issues by keeping every stage of filtration safely contained.

- Risks of Exposure to Air and Temperature Loss: Air contact oxidizes sensitive chemicals, ruining quality. Temperature drops in mining slurries cause settling issues or viscosity changes. One mining site reported 12% efficiency loss from heat escape in open filters. Leaks add another layer of risk—spilling hazardous fluids and creating environmental violations with fines reaching thousandsof dollars per incident. Leaf filters eliminate these risks by maintaining a completely sealed process chamber.

- The Sealed and Insulated Design of Leaf Filters: NHD’s automatic leaf filter uses a fully enclosed vessel with insulation options. This keeps temperatures steady, even in cold climates. The vertical leaf filter includes a hydraulic fast-open device for quick access without breaking the seal often. Pressure relief pots and isolation valves add layers of control. In practice, this means stable filtration at from 0.6 MPa working pressure, handling moderateto high-viscosity media without slowdowns. It’s built for real-world demands in mining filtration.

- Protect Both Product and Environment: Enclosed systems stop leaks, protecting workers and the surroundings. No evaporation means less waste.In chemical applications, this design helps meet strict environmental regulations, such as EPA standards. Mining plants also benefit from reduced runoff and cleaner site management.

Capture Fine and Difficult-to-Settle Suspended Particles

Some particles just won’t settle. Traditional methods let them slip through. NHD advanced leaf filters grab them reliably, no extras needed.

- The Limitation of Traditional Sedimentation: Gravity settling works for big chunks but fails on fines under 10 microns. In mining, these float forever, clouding water reuse. Chemicals see similar problems with colloids. Tanks sit idle waiting, eating into profits. One report pegged sedimentation inefficiency at 25% loss in throughput. Fine filtration equipment, like leaf vertical filters, outperforms here by forcing separation.

- Superior Filtration for Micron-Level Particles: NHD’s automatic leaf filter targets microns with polymericfilter tubes that require no filter cloth, allowing direct filtration. The fine pore structure minimizes the initial “cake formation” stage compared with traditional leaf filters. Leaves wrapped in stainless steel perforated plates collect solids precisely. It handles hard-to-filter media at viscosities that stump others. In mining filtration, the unit processes slurries in vessels up to 0.8 m³ volume, consistently achieving filtrate turbidity below 1 NTU. It’s fully automatic cycle control allows operation by preset time or pressure, ensuring consistent clarity and repeatable performance with minimal operator input.

- No Need to Add Any Flocculants: Flocculants clump particles but add costs and residues. NHD’s system skips them entirely. Pressure drives filtration, with backwash discharging cake without chemicals. This cuts OPEX by 10-20% in chemicals and mining. As fine filtration equipment, it keeps processes pure from start to end.

Achieve Clean Filtrate & Lower OPEX with NHD Leaf Filters

The NHD automatic leaf filter is a new-generation system designed for both concentration and fine filtration. Built for versatility, it operates under pressures up to 1.0 MPa, efficiently processing low-solid, high-viscosity, and hard-to-filter media. With fully automated operation, extended filter element life, and low maintenance costs, it represents one of the most advanced fine filtration solutions available today—delivering higher efficiency with minimal labor.

Equipment Advantages

- Automated Operation: Fully automatic running with low labor intensity and simple operation reduces manual effort.

- Enclosed & Eco-Friendly: Fully enclosed operation ensures long cloth life, zero leakage, and no environmental pollution.

- Water-Saving& Self-Cleaning: High-efficiency self-cleaning with backwash discharge enables cloth recovery without water consumption, effectively reducing evaporation load.

- Smart Control System: PLC with touchscreen provides reliable operation control.

- Triple Safety Protection: Unique triple pressure overload protection guarantees absolute safety.

- Quick-Access Design: Hydraulic fast-opening device allows easy head access.

- Efficient Sludge Concentration: The filter cake settles at the vessel bottom after cloth stripping, achieving high-concentration sludge discharge in the next cycle.

- Emergency Isolation: Isolation valves enable immediate single-element shutdown during abnormalities.

- Durable Pneumatic Valves: Specialized pneumatic valves offer reliable performance with excellent dynamics and longevity.

- Enhanced Material: Using polymer filter elements enhances filtration precision.

These features collectively lower operational expenditure (OPEX) by reducing water use, minimizing downtime, and enhancing safety. Product parameters vary by model.

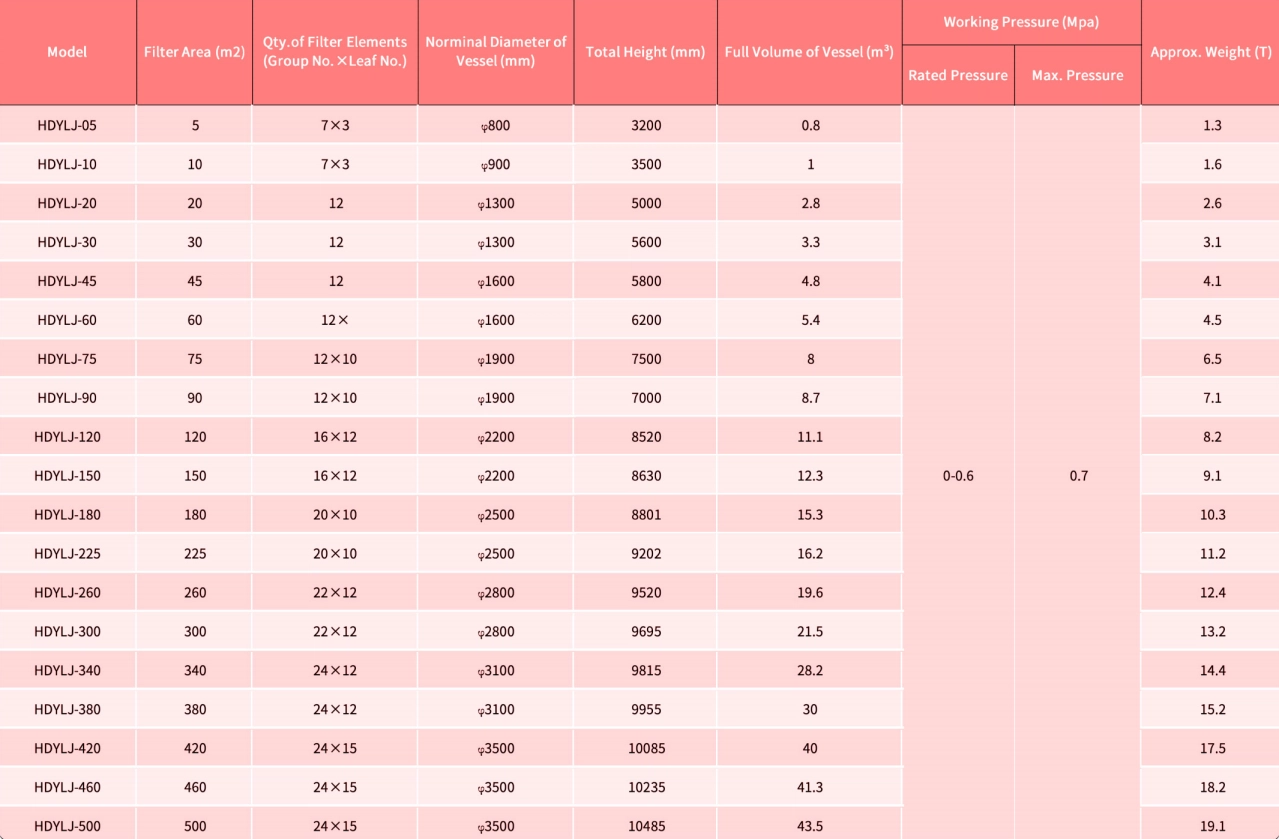

Here’s a table for key specs:

These specs show scalability from 5 m² to 500 m² areas, fitting small labs to large plants. Max pressure hits 0.7 MPa for demanding tasks.

Conclusion

Facing the challenging demands of precision filtration in the chemical and mining industries, the NHD otomatik yaprak filtresi, with its sophisticated design, fully enclosed structure, and intelligent automated control, not only achieves superior filtration results technically, but also creates significant value for users in terms of economic efficiency and environmental compliance. Models like the HDYLJ-500 offer vast 500 m² areas and robust 43.5 m³ volumes, ensuring high throughput without sacrificing purity.

Choosing NHD means choosing reliability, purity, and efficiency for your production processes. Contact us today at [email protected] for a custom quote. Let’s discuss how our vertical leaf filter can fit your needs.