In the world of chemical processing, sulfuric acid production is vital for industries like fertilizers, mining, and petroleum refining. The equipment chosen can greatly affect efficiency. Sulfuric acid systems need careful precision. Even tiny mistakes in distribution can cause uneven reactions, higher energy use, or expensive shutdowns. The drying and absorption towers are the core of these plants. They deal with harsh, corrosive liquids at high temperatures. The acid distributor plays a key role in keeping everything running well.

Traditional setups have worked fine for many years. But as plants grow larger and rules on emissions and waste get stricter, there’s a need for better solutions. This is where new designs shine. They mix trusted methods with modern materials to solve old problems. The tube-trough acid distributor is one such new idea. It’s becoming popular in today’s facilities.

Sulfuric Acid Distribution: Key Challenges and Considerations

Sulfuric acid production hinges on effective gas-liquid interaction, and sulfuric acid distributors are key to spreading acid evenly across tower packings. Yet, traditional designs—trough and pipe types—often fall short under real-world pressures. Trough type distributors offer simplicity but struggle with uneven flow, while pipe versions provide control at the cost of frequent clogging. These issues ripple outward, affecting not just individual towers but entire production lines. The bigger picture reveals why these challenges matter: inconsistent distribution lowers yields, corrosion shortens equipment life, and mist entrainment harms both the environment and downstream processes. As global demand for sulfuric acid—over 200 million tons annually—grows, addressing these flaws becomes critical for staying competitive.

Trough Distributors: Simplicity vs. Limitations

Trough type distributors rely on open channels to let gravity distribute acid, a straightforward approach that works for low-pressure systems. However, this simplicity comes with drawbacks. Even minor unevenness in tower leveling can cause liquid to pool irregularly, creating dry spots or excessive splashing. Such maldistribution disrupts gas–liquid contact, and studies indicate that absorption efficiency can drop by up to 15%. Operationally, plants often need frequent adjustments—sometimes every six months—because of the tower’s height and complexity, increasing downtime and maintenance costs. Corrosion presents another challenge: in concentrated acid at around 100 °C, standard construction materials may only last five to eight years, resulting in repeated replacement cycles and higher life-cycle costs.

Pipe Distributors: Control with Trade-offs

Pipe distributors rely on drilled holes or slots to release acid with accuracy. This careful approach works well in complex tower designs. It shines in high-flow situations. However, this control has its drawbacks. High-quality stainless steel pipe distributors resist corrosive environments. Still, they struggle with sediment or polymer buildup, especially in dirty acid streams. This often causes clogging. Corrosion remains a problem too. Without anodic protection, 304 stainless steel in concentrated acid at 150 °C may fail in under five years. The trade-off is obvious: better control means more upkeep. This burden grows as plant size increases.

The Bigger Picture: Why These Challenges Matter

These limitations aren’t isolated problems; they impact the entire sulfuric acid production chain. Uneven distribution reduces mass transfer efficiency and, in some cases, lowers yields by 10-20% Corrosion further drives up costs—replacing a distributor can hit $50,000 or more, excluding production losses from downtime. Mist entrainment adds another layer of risk, as acid escaping in aerosol form can trigger environmental compliance challenges, with fines often reaching tens of thousands of dollars annually. Together, these challenges highlight the need for improved solutions. The tube-trough acid distributor was developed specifically to address these concerns, offering a smarter and more reliable approach.

NHD Tube-Trough Acid Distributor: The Innovative Solution

Shifting focus to practical innovations, NHD’s tube-trough acid distributor stands out as a game-changer for sulfuric acid production. Developed through collaboration with top research institutions, this device integrates the best of trough and tubular designs into a single, efficient system. The goal is not simply to merge shapes, but to engineer a distributor that delivers consistent performance under the harshest operating conditions.

At its core, the design uses overflow downcomers arranged in a trough-like structure with tubular outlets for precise acid release. This configuration enables smooth liquid flow without the splashing or maldistribution common in older designs, thereby minimizing mist formation. The free section area reaches up to 68%, allowing unobstructed gas passage while maintaining even acid distribution.

Material selection is another defining feature. The distributor is manufactured from HD-1 high-silicon alloy stainless steel, a proprietary material jointly developed by NHD and the National Institute of Metal Research at the Chinese Academy of Sciences. HD-1 incorporates high silicon content for exceptional corrosion resistance in high-temperature concentrated sulfuric acid. It forms a protective black film on the surface, shielding against degradation without needing anodic protection. In practice, this means service lives exceeding 10 years, based on field data from over a dozen plants.

Core Advantages of the NHD Design

Diving deeper into what makes this distributor stand out, let’s break down its key features.

- Superior Distribution Uniformity: With at least 42 points per square meter—customizable higher if needed—the acid spreads evenly, boosting moisture absorption and mass transfer. This directly translates to higher conversion rates, often improving efficiency by 10-20% in absorption towers.

- Anti-Clogging Performance: The overflow structure resists blockages from sediments or polymers. Unlike pipes that plug up, this design allows visual inspection during operation, so issues get spotted early. Plants report reduced downtime, with some going years without major cleanings.

- Lower Acid Distribution Velocity: In tube-trough distributors, the velocity inside the acid pipes is maintained at approximately 0.5–0.65 m/s, compared with around 1.1 m/s in conventional pipe distributors. This lower flow rate minimizes the impact on ceramic rings, thereby reducing acid mist formation and ensuring more stable and safer operation.

- Low Pressure Drop and Stability: Gas flow encounters minimal resistance, avoiding short circuits and entrained mist. Pressure losses stay low, which cuts energy needs for fans and pumps.

- Exceptional Durability from HD-1 Alloy: High corrosion resistance means no extra protection systems. The alloy’s mechanical strength holds up in temperatures up to 150°C, and its cold/hot forming adaptability eases fabrication. In addition, composite flanges (HD-1 for wetted parts, 316L elsewhere) keep costs down—users save 30-50% compared to full imports.

These advantages aren’t theoretical; they’ve been proven in sulfuric acid plants across China, where units have operated reliably for over a decade.

Tube-Trough vs. Traditional: A Direct Technical Comparison

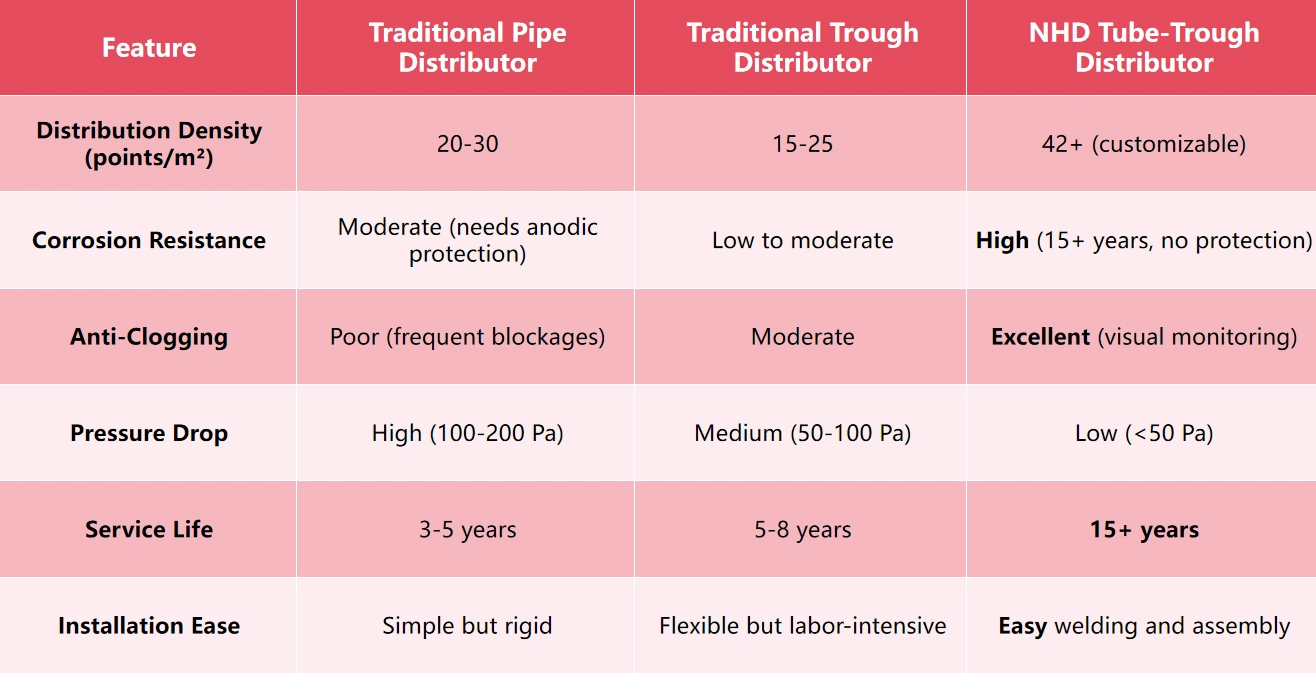

To truly appreciate the leap forward, a side-by-side look at tube-trough versus traditional distributors reveals stark differences. Traditional pipe distributors excel in simplicity but lag in longevity, while trough types offer broad coverage at the expense of precision. The tube-trough hybrid addresses these without compromise.

Here’s a comparison table based on typical performance metrics from industry benchmarks:

Why Choose NHD Acid Distributor?

With more than 30 years of experience in chemical engineering, NHD has developed a comprehensive product portfolio that includes filters, agitators, and pressure vessels. The tube-trough acid distributor is not a standalone product but an integrated component within complete solutions for drying towers, absorption bodies, pipelines, and auxiliary systems such as anti-eddy devices and packing grids.

Quality assurance is supported by industry recognition. The distributor has been evaluated and approved by the Nanjing Chemical Institute as an ideal solution, while also meeting international certification standards such as SGS and ISO.

Field applications further demonstrate the value of the design. A major power plant in Shandong reported a 12% increase in output and no corrosion issues after eight years of operating NHD tube-trough distributors as replacements for aging pipe distributors. Similarly, a chemical producer in Guangdong retrofitted an older absorption tower with the new design and achieved a 50% reduction in maintenance costs.

These cases underscore NHD’s commitment to quality. Beyond equipment supply, NHD serves as a full EPC partner, providing end-to-end support from engineering and design through to installation and commissioning.

Conclusion

Choosing the right acid distributor isn’t just about immediate needs—it’s about long-term sustainability in a demanding industry. The tube-trough acid distributor from NHD offers a reliable, cost-effective path forward, enhancing efficiency while slashing upkeep.

If you’re dealing with sulfuric acid equipment challenges, consider how this next-generation solution could fit your setup. Reach out to NHD today at [email protected] for tailored advice or a quote. Our team is ready to discuss your project and provide the support you need to keep operations humming.