In industrial gas scrubbing, mist eliminators are the final safeguard against harmful emissions. Yet when fluoride-rich gases release hydrogen fluoride (HF), conventional glass fibre bed filters corrode quickly, causing high costs and compliance risks. This article explains why traditional mist eliminators fail in HF environments and how carbon fibre candle filters provide a durable, long-term solution.

The Hidden Threat: How Fluoride in Flue Gas Damages Mist Eliminators

Fluoride finds its way into flue gas through the ores used in smelting. Copper, zinc, and lead smelting often deal with these high-fluorine ores. When heated, the fluorine transforms into HF gas, a strong acid that complicates filtration efforts across industries.

How Does HF Acid Destroy Glass Fibre Filters?

HF acid doesn’t play nice with glass fibre bed candle filters. Commonly used in absorption towers, these fibre bed filters start to break apart under HF’s attack. Reports suggest their lifespan can shrink from several months to just a few weeks in severe cases. The fibers weaken, letting more particles slip through and forcing plants to replace them often.

What is the Impact of HF Corrosion on Mist Eliminators?

The fallout from HF corrosion hits hard. More frequent filter changes mean higher maintenance bills and lost production time. Emissions might climb above legal limits, risking penalties or shutdowns. For operations handling pyrite or other fluoride-heavy materials, this turns into a recurring problem that demands a better approach. The properties of fluoride compounds make carbon fiber—a corrosion-resistant material—a strong contender, offering a new solution for demanding conditions.

Why Carbon Fibre is the Ultimate Answer to HF Corrosion

- The Innately Corrosion-Resistant Warrior: Carbon fibre stands out because it doesn’t react with HF acid. This makes carbon fibre candle filters ideal for smelters and chemical plants where fluoride gases are common. Their ability to resist corrosion means they last longer, reducing the need for constant upkeep.

- Superior Mechanical Strength & Capture Efficiency: Beyond durability, these filters deliver solid performance. Carbon fibre bed candle filters catch tiny acid mists using Brownian diffusion—where small particles bump into fibers—and inertial impaction, where bigger ones collide with them. This catches over 99% of particles under 3 microns and 100% above, keeping emissions well below 20 mg/m³. Plants can rely on these filters to keep working steadily, even in the tough flue gases from non-ferrous smelting. This combination of toughness and efficiency sets them apart from older options.

With such a bright future ahead for carbon fiber, it’s worth taking a closer look at how it compares to fiberglass. The next section provides a clear comparison to guide your choice.

Carbon Fibre vs. Glass Fibre: A Performance Showdown

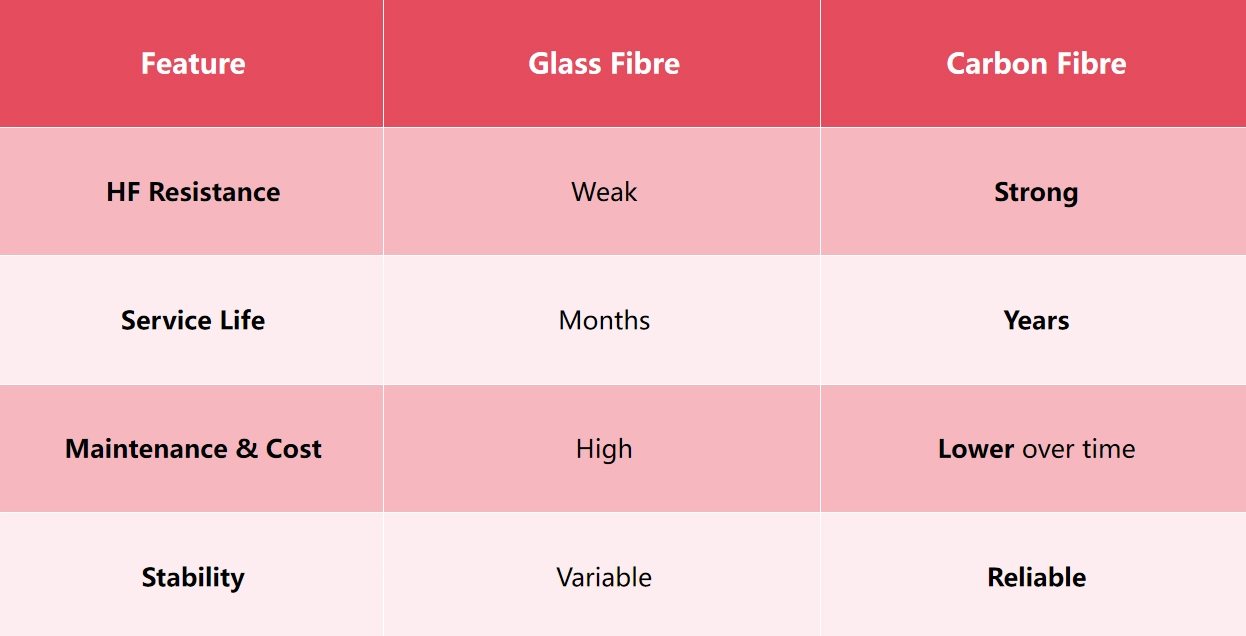

- HF Corrosion Resistance: Glass fibers quickly shatter in the presence of HF acid, while carbon fibers remain intact. This difference alone makes carbon fibers more suitable for high-fluorine environments.

- Service Life: Carbon fiber filter cartridges have a significantly longer service life than glass filter cartridges, which means less downtime and fewer replacements.

- Maintenance Frequency & Cost: Although glass filters have a relatively low initial price, their short lifespan often leads to increased expenses due to frequent replacements. Carbon fiber filters have a longer lifespan, which reduces annual costs even with a higher initial price.

- System Stability: Compared to glass fiber, carbon fiber can ensure smooth system operation. Less corrosion means less efficiency loss or leakage, thus providing stable operation for process filtration.

Here’s an intuitive comparison chart:

This comparison highlights carbon’s edge. Now, let’s explore how NHD turns this technology into real-world solutions.

NHD Promise: A Dedicated Solution for Harsh Conditions

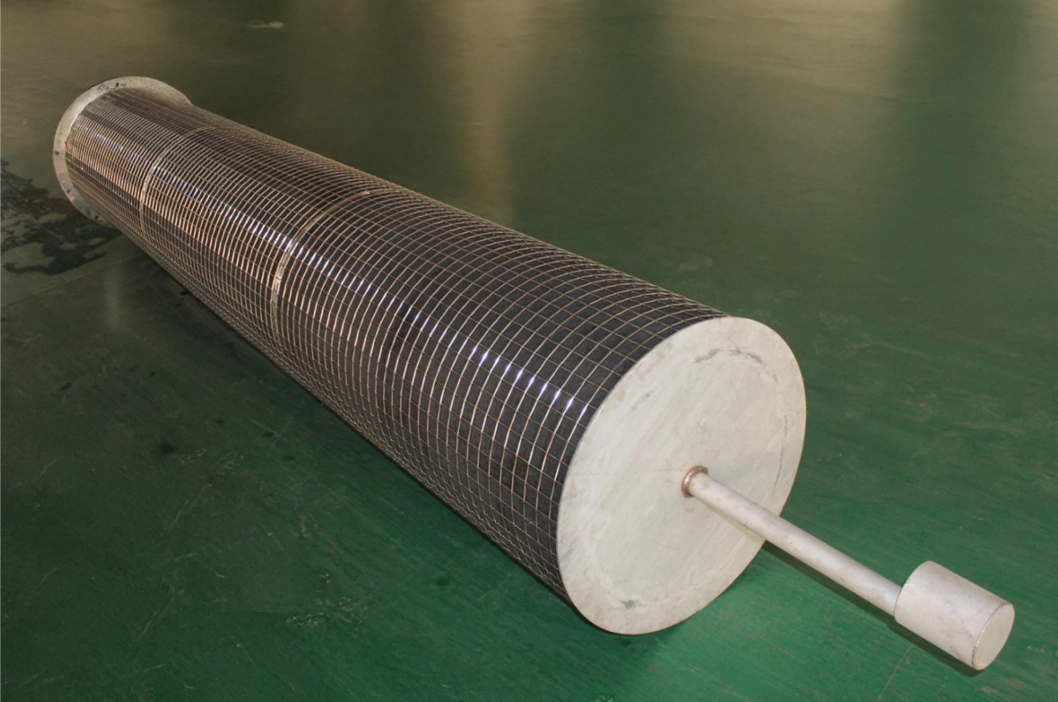

NHD, a professional manufacturer specializing in industrial filtration equipment for 30 years, is deeply aware of the challenges of fluoride gas treatment. Leveraging years of industry insight and a deep understanding of the industry’s pain points, NHD designed carbon fiber candle filters to address corrosion issues in smelting and chemical plants.

The Foundation of Quality: Premium Carbon Fibre Materials

As a leading candle filter manufacturer, NHD stands out for its high-quality carbon fiber material, which significantly improves the effectiveness of candle filters in gas scrubbing applications.

Beyond its use in ore smelting, NHD’s carbon fiber candle filter also supports flue gas desulfurization, helping the plant meet clean air standards. This initiative contributes to environmental goals, making NHD a key player in this field. Furthermore, customized services ensure that each filter performs to its full potential. Leveraging NHD’s expertise, putting these filters into operation becomes the next priority. The following sections provide practical steps for achieving this conversion.

Implementing Carbon Fibre Candle Filters in Your Plant

Begin by testing your gas stream for HF levels. If the HF concentration exceeds the standard, carbon fiber filter cartridges may be the solution. Partner with NHD to choose the right model—options like C7 or C7k cater to high-efficiency or high-speed needs, with specs for 100% removal above 3 microns and 99% below.

Installation fits into existing absorption towers, available in hanging or standing types. Watch the bed velocity, keeping it under 0.2 m/sec for top performance or 1.0 m/sec for general use. Pressure loss should hover between 150-250 mm H₂O to maintain smooth gas flow.

Consider a multi-stage setup with other fiber bed mist eliminators to catch a broader range of particles. Regular inspections keep everything on track. Many plants report cleaner emissions and fewer repairs within a few months, proving the value of this upgrade.

Conclusion

Fluoride-rich gases push mist eliminators and candle filters to their limits. NHD’s carbon fibre candle filters rise to the task, offering unmatched resistance and steady performance. For smelters or chemical plants, they mean fewer headaches and better air quality.

With over 200 patents and operations in over 50 countries, NHD has become the industry benchmark for chemical filtration equipment. With over 30 years of experience in R&D and manufacturing, we are a leading manufacturer of candle filters. We are committed to providing our partners with first-class products and services. Contact us today at [email protected] for your personalized solution to improve your process filtration and handle hydrogen fluoride (HF).