In the morning, you pour hot water over coffee grounds, waiting for that perfect drop of coffee to trickle into your cup—but if the filter fails, you’ll find only grounds filling your cup. Now scale this problem up to the alumina industry, and the consequences become far more serious. In alumina production, the Bayer process generates vast quantities of red mud, a dense and highly alkaline slurry filled with fine particles. Handling this byproduct is one of the toughest challenges in industrial filtration. Traditional filters often struggle with such material, resulting in low throughput, frequent maintenance, and unscheduled downtime. The inefficiency doesn’t just slow production—it drives up costs, increases environmental risks, and puts added pressure on operators to maintain stability.

This is why disc filters have become a staple in alumina production. They extract solids from the liquid with a smooth, uninterrupted flow, increasing yield while reducing waste. Whether you’re expanding your plant or resolving production challenges, mastering the power of disc filters can help you succeed. Let’s explore why they excel and how they achieve this.

The Red Mud Filtration Challenge: More Than Just Separation

Red mud filtration is more than a back-end step—it sits at the heart of alumina production, influencing recovery rates, energy consumption, and environmental impact. To understand its role, we must start with the Bayer process.

Here, bauxite ore is ground and mixed with caustic soda under heat and pressure. This pulls out alumina, leaving red mud behind. For every ton of alumina, 1 to 1.5 tons of red mud are generated. This waste carries fine particles, often under 10 microns, with a high pH near 13, and a sticky texture that clings to everything. Effective washing and filtration are therefore critical. It boosts alumina recovery, cuts energy use in evaporation stages, and minimizes the burden of red mud disposal.

But getting it right isn’t easy. Traditional equipment—such as rotary vacuum drum filters and plate-and-frame presses—once dominated the industry. These rely on vacuum or pressure to form filter cakes, and they perform reasonably well on coarser slurries. But when it comes to red mud, their weaknesses are exposed: cycles drag on, filter cloths clog quickly, and maintenance costs escalate. These limitations create efficiency bottlenecks that ripple across the entire alumina plant.

The Efficiency Bottleneck

Speed tells the tale. A drum filter might take 5-10 minutes per cycle, leaving cakes with 25-30% moisture. Red mud’s tiny particles block pores fast, dropping flow to a trickle. One alumina site reported 15% less daily output due to this drag. The ripple hits washing stages, where extra water taxes evaporators.

The strain extends to equipment reliability. Pumps and valves can wear out faster under uneven loads, pushing repair costs up. Operators frequently adjust settings in search of stability, but traditional batch-style systems struggle to keep pace with the continuous and demanding nature of red mud processing. This leads to the next pain point: downtime.

The High Cost of Downtime

Imagine what happens if a production line suddenly stops. In alumina production, every hour of downtime can cost $10,000 or more in lost production. Traditional filters need stops every 4-6 hours for cleaning, with red mud’s stickiness triggering extra pauses.

Labor costs also increase. Technicians spend hours scraping buildup or realigning parts, diverting them from higher-value tasks. Consumables add to the expense: Replacement cloths or seals aren’t cheap—overhauls can hit $50,000. Safety risks grow too, with spills and caustic exposure during rushed fixes. With downtime costs mounting, the case for more reliable solutions becomes clear.

The Ripple Effect on Energy Consumption

When cakes carry excess moisture, downstream evaporators kick into overdrive. A 5% moisture hike can add 10-15% to energy use, translating to thousands of dollars monthly. Traditional disc filter alternatives often leave liquid trapped, forcing plants to burn more steam or gas. In alumina production, where energy is a top expense, this weakness hits hard. Beyond direct costs, wasted energy strains equipment service life. Motors run hotter, seals degrade, and maintenance cycles shorten.

Environmental and Safety Pressures

Red mud’s environmental footprint looms large. Wet cakes from outdated systems need bigger ponds, increasing land use and leaching risks. A single alumina plant can generate more than 2 million tons of red mud annually, and excess water means more trucks and emissions. Regulators are tightening oversight: agencies such as the EPA and frameworks like Europe’s REACH impose strict compliance rules, with penalties for violations reaching €1 million.

Safety concerns add further urgency. High-pressure presses can fail if seals burst, while drum filters expose workers to moving parts and caustic slurry. In confined spaces, even minor spills can create hazards. Filtration equipment must therefore not only perform efficiently but also contain risks to protect both people and the environment.

Why the Disc Filter Emerges as the Definitive Solution

The vertical disc filter, a veteran of filtration equipment, uses a series of submerged discs to pull solids steadily from slurry. It operates continuously and automatically based on the principle of vacuum filtration. For alumina red mud filtration, this approach turns chaos into control, offering a lifeline for struggling plants.

The Principle of Continuous Operation

At its heart, the disc filter relies on vacuum power. Multiple discs, wrapped in filter cloth, dip into the slurry tank. As they turn slowly—around 0.5 to 2 rpm—vacuum draws liquid through, leaving a thin cake on each face. Cakes rise for drying, then scrape off into chutes. Air blasts clear leftovers, and the cycle rolls on.

Automatic disc filter runs with little oversight. A central valve manages phases: cake forming, drying and discharge. For challenging red mud slurries, the filter cloths reliably handle particles down to 5 microns, producing cakes at 18-22% residual moisture.

Maximum Efficiency in a Compact Design

Alumina plants often wrestle with limited floor space—tanks, reactors, and conveyors fill every corner. Disc filters shrink that burden. A 120 m² unit fits in 10×15 meters, compared to 20×25 for equivalent rotary drums. By stacking discs vertically, the filtration area expands without widening the footprint.

The internal design further enhances efficiency. Shorter pipes reduce pressure losses, lifting filtrate rates by up to15%. Despite the higher capacity, energy demand remains modest: mid-size models typically draw only 20–30 kW through vacuum pumps. In disc filtration systems, this design frees room for growth, a big win for space-conscious operators.

Naturally Suitable for Alumina Production

Red mud challenges any filtration system with its extreme fineness and alkalinity, yet disc filters are engineered to meet these demands. Specialized filter cloths, resistant to pH 12-14, deliver service lives of 6-12 months. Vacuum settings match slurry density, pulling clear liquor for caustic recovery—up to 95% reused. In Bayer loops, this cuts the fresh soda needs.

For metallurgical equipment users, integration is seamless. Disc filters allow remote control adjustments and can be equipped with automatic back washing for fully unattended operation. The resulting drier filter cakes lower downstream drying requirements and boost overall production efficiency. These features provide a solid foundation. At NHD, we build on this foundation, advancing the performance of alumina red mud filtration.

Beyond Standard: The NHD Disc Filter Advantage

NHD’s automatic vertical disc filter takes the core design and adds refinements from 30 years of fieldwork experience. It’s filtration equipment shaped for the toughest alumina production challenges.

- Compact & Efficient Design: NHD disc filters are compact and powerful, making them the first choice for alumina production bases with limited space. Each disc offers a filter area of 20–50 m², with disc diameters reaching up to 7 meters. A single unit still provides a maximum filter area of 240 m² within a compact footprint. This design cuts weight by 10% thanks to thinner spokes, simplifying installation and reducing structural demands on facilities. Optimized manifolds enhance filtrate flow by 25% compared to standard models, ensuring faster processing without sacrificing quality. The result is a setup that maximizes output while fitting snugly into existing layouts, leaving room for future expansions or additional equipment.

- Reliable Operation & Easy Maintenance: Maintenance is streamlined through features like the lightweight filter plates designed for quick and convenient cloth replacement, significantly lowering labor intensity. Further enhancing reliability, the unique distribution valve minimizes cloth wear from friction, while the highly reliable shaft seal prevents energy loss and allows for easy adjustment. The addition of a quick-discharge system via a pneumatic butterfly valve provides an effective safeguard against material sedimentation during unexpected downtime.

- Cost & Energy Savings: When it comes to Cost and Energy Savings, the filter delivers efficiency on multiple fronts. Its large-diameter disc design achieves a high filtration area within a compact footprint, directly reducing building expenses. This efficiency is amplified by an expanded filtration and drying zone from the multi-disc layout, which boosts overall capacity. Operational costs are further reduced by a high-pressure automatic centralized dry lubrication system that ensures optimal grease distribution and by design features that prevent sediment buildup, minimizing downtime and maintenance needs.

- Environmental & Safety Benefits: Sustainability takes center stage with NHD’s advanced design. Its sealed design effectively eliminates leaks, spills, and secondary pollution during production. Furthermore, the integrated systems for preventing material sedimentation and crystallization not only ensure process continuity but also contribute to a safer and cleaner workplace.

Proven in Practice: NHD Disc Filter Application Cases

Theory meets reality in the field. Consider the case of a 500,000-ton-per-year alumina plant in Shandong, China, which was facing the very challenges we’ve discussed: frequent clogging, high-moisture filter cake, and escalating operational costs.

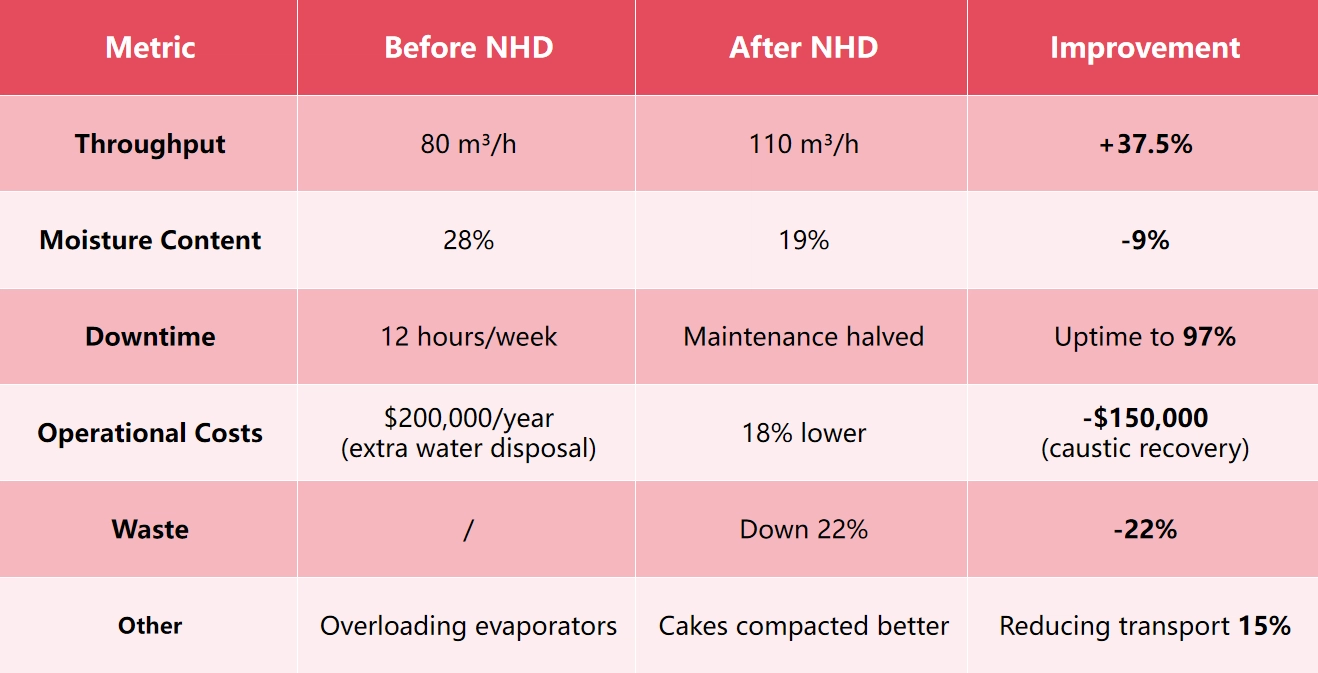

Before NHD:

- Rotary drums managed 80 m³/h but left 28% moisture, overloading evaporators.

- Downtime hit 12 hours weekly for cleanings.

- Disposal costs reached $200,000 yearly from extra water.

- Energy use climbed 25% in drying.

After a 240 m² NHD disc filter:

- Throughput rose to 110 m³/h, moisture to 19%.

- Uptime reached 97%, maintenance cut in half.

- Caustic recovery gained 8%, saving $150,000.

- Cakes compacted better, reducing transport by 15%.

- Output Boost: +25% solids daily.

- Cost Drop: 18% lower ops costs in year one.

- Green Gains: Waste down 22%.

Conclusion

Selecting the right filtration technology is crucial for alumina production, driving efficiency, cost control, and environmental care. NHD disc filters go beyond mere equipment; they are a strategic advantage for boosting competitiveness and fostering sustainable growth. Ready to tackle your red mud filtration challenges? Contact NHD today at [email protected] for a tailored solution and elevate your operations!