A filter press is one of the most important pieces of equipment in factory solid-liquid splitting tasks. Knowing the right ways to run this equipment matters a lot. It helps keep work smooth, stays safe, and makes the system last longer. This full guide gives clear details on how to use a filter press. It covers basic ideas to helpful care tips.

Overview of a Filter Press and Its Uses

Filter presses act as key splitting equipment in many fields. They give steady and quick ways to take solids out of liquid mixes.

What a Filter Press Is and Its Main Job

A filter press is a batch-run separation equipment. It takes solids away from liquids by pushing slurry through under force. It splits solids from liquids. Slurry goes under pressure into many filter rooms made by filter plates. Solids stay as filter cake. Clear liquid goes through the filter media. The equipment works by filtering, cake cleaning if needed, and machine drying.

Common Factory Uses

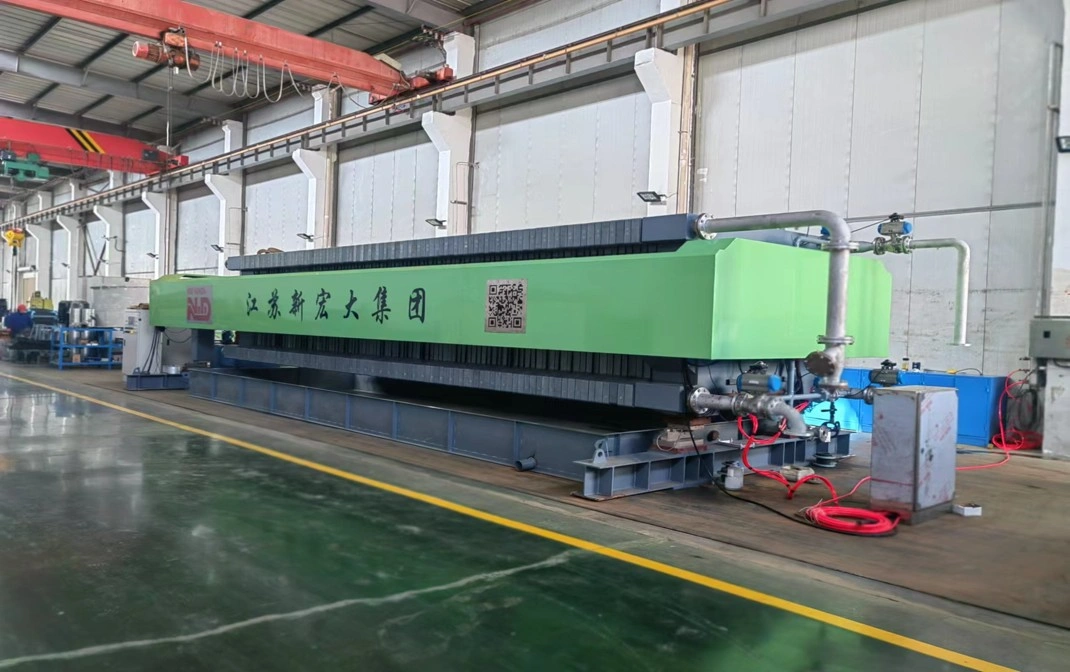

The NHD HDLY Vertical Automatic Pressure Filter comes from NHD. It builds on top local and world filter press skills. It finds wide use in areas like non-ferrous metal work, melting, titanium dioxide making, chemical work, coal readying, food, ceramics, paper making, sugar work, dye making, and waste water care. These many uses show how flexible and trusty NHD filter press tech is in different factory areas.

Parts and How a Filter Press Works

Knowing main parts and work rules is key for right use and care of a filter press.

Main Parts and What They Do

A normal NHD vertical automatic filter press has many vital parts that work together:

- Filter plates: Hard frames that make sealed filter rooms when shut.

- Filter cloth: The see-through layer put over each filter plate. It holds solids but lets liquid pass.

- Diaphragm (membrane): Bendy sheet built into the filter plate. It gives extra push to the filter cake.

- Hydraulic system: Gives hold force to seal the plate group. It powers auto work.

- Filtrate manifold: Gathers and sends out clear liquid from all rooms.

- PLC control system: Runs cycle order by itself. It watches pressure and keeps safety locks.

- Pneumatic valves and air blow system: Help dry cake and clean the system.

The filter cloth is the part that gets changed for filtering. The filter plate group is the main build and work unit.

How Filtering Happens

When slurry first touches the filter cloth, bigger bits get caught on the cloth top. They make a hole-filled “bridge” layer. This is the start filter cake. As filtering goes on, this cake layer does the main filtering job. It catches smaller bits step by step. The liquid part, called filtrate, keeps going through the filter cake and the cloth below. This keeps splitting steady all through the cycle.

Step-by-Step Normal Running Guide for Filter Press Use

Right running steps are needed for best work and to keep equipment strong.

Checks Before Starting

Before any filtering round begins, workers must do full checks first:

- Make sure all air and hydraulic links are tight and do not leak.

- Look at filter cloths for harm, good pull, and right fit.

- Check that safety locks, quick stops, and pressure let-go systems work.

- Be sure feed pumps, control valves, and PLC system run well.

- See that all hand valves sit in start spots.

Detailed Operating Steps for Filter Press Filtration Cycle (Total 6 Steps)

Step 1 – Feed Part Slurry gets pumped into the shut filter rooms by the feed line. Under force, liquid goes through the filter cloth and cake layer. Solids build up to make filter cake. Filtrate gathers and leaves by the filtrate line. When feeding ends, the feed line gets cleaned by itself. This stops leftover build-up. Watch feed force, flow speed, and filtrate clearness all the time in this part.

Step 2 – Diaphragm Push High-force water or air goes into the diaphragm room behind the sheet. The diaphragm grows toward the filter cake. It puts even extra force to push more liquid out of the cake.

Step 3 – Cake Cleaning (If Needed) Cleaning liquid enters the filter rooms. It pushes out leftover start liquid or things that dissolve. Wash liquid goes through the cake and filter cloth. It leaves by the filtrate line.

Step 4 – Air Drying Pressed air blows into the shut filter rooms through feed openings. This pushes out leftover liquid from the cake, diaphragm room, and filtrate lines. It gets the most dryness before letting out.

Step 5 – Plate Group Opening and Cake Letting Out The hydraulic hold system lets go of force and pulls back. Filter plates part one by one. The auto cloth-shake equipment starts. It makes dry filter cake fall off and drop into the gather bin below.

Step 6 – Filter Cloth Cleaning High-force wash sprays turn on one side then the other for each filter cloth. They take off stuck bits and bring back see-through ability. The system then shuts the plate group. It gets ready for the next round.

Safety Steps and Care Rules

Safety and care plans are basic for good filter press running and worker protection.

Safety Rules While Running

Workers must follow strict safety ways in all parts:

- NHD systems have three-level force overload guards for full running safety.

- Always put on right PPE: safety glasses, gloves, and guard clothes.

- Never open the press when under force. Check full force release by gauges and PLC signs first.

- Use lockout/tagout ways when caring.

- Hold regular safety lessons and quick response practice.

Normal Care Ways

Regular care keeps best work and makes equipment last longer:

- Filter cloth: Look every day. Change if torn, blocked, or if filtering time goes over start by more than 30%.

- Hydraulic system: Check fluid amount, state, and force each week. Change fluid by maker plan.

- Seals and gaskets: Look when changing cloth each time. Change if cracked or bent.

- PLC and sensors: Set pressure and spot sensors right every three months. Update software when NHD sends it.

- Auto cloth washing: Check spray force and cover in each round.

NHD systems have full auto, side-by-side cloth washing with self-check fix. This cuts hand work a lot.

NHD – A Trusted Maker of Factory Filtering Equipment

New Hongda (NHD) has led in making filtering equipment since starting R&D in 2005. Over 200 units work well around the world. This big know-how shows NHD’s push for new ideas and happy customers.

The NHD product list has top vertical and horizontal filter press systems. They fit exact work needs. The four-column vertical build gives small floor space. The biggest 168 m² model needs about 15 m × 6 m of floor room, not counting helper equipment. The build in parts lets take apart and move with little stop time.

Summary

Filter press running needs careful follow of steps, safety rules, and care ways. Knowing filtering ways, following set round order, and using full care plans keep equipment at top work and long life. NHD vertical automatic filter presses bring in top auto features. These include PLC control, self-check, and far watching. They give high speed, low work need, and steady safety following. Success comes from worker lessons, step control, and active care.

FAQs

Q1: What kinds of stuff can go through a filter press?

A: NHD filter presses take many slurries in chemical, oil, food, drug, metal, and waste water care jobs. System set-up like cloth kind, plate stuff, diaphragm fits slurry thickness, bit size, and chemical match.

Q2: How often do I change the filter cloth?

A: Change times depend on slurry roughness, solids amount, and wash success. Watch round time and filtrate state. Change cloths when filtering time grows a lot or when eyes see blocking, tears, or stretch. Normal life runs from some weeks to some months in hard jobs.

Q3: Can filter presses run by themselves?

A: Yes. NHD systems have full auto by PLC with touch screen HMI, self-alarm checks, and far watching. The whole round—feeding, pushing, cleaning, drying, letting out, and cloth wash—goes with little worker help. This keeps steady work and cuts work.