In sectors where separating solids from liquids is crucial, filter presses play a key role in delivering effective and affordable outcomes. Two popular kinds are chamber filter presses and membrane filter presses. Knowing how these two differ is important when picking the best tool for specific industrial tasks.

Overview of Filter Press Technology

Filter press technology is a hands-on way to split solids and liquids using pressure. It’s widely used because it works well, can grow with needs, and fits into many fields.

Basic Principles of Solid-Liquid Separation

The main idea of a filter press is simple. Slurry gets pumped into filter chambers. Pressure pushes the liquid through a material, often cloth, leaving solid chunks behind. Over time, these chunks pile up into a cake. When the chamber fills up, it’s time to empty it out.

Common Applications Across Industries

Filter presses are common in many areas like chemical production, mining, metalworking, food making, medicine, and cleaning wastewater. The HDLY Vertical Automatic Pressure Filter, created by New Hongda, builds on the newest press filter ideas from around the world. It’s used in fields like non-ferrous metals, smelting, titanium dioxide, chemicals, coal sorting, food, pottery, paper, sugar, dyes, and wastewater handling.

Features and Operation of a Chamber Filter Press

Chamber filter presses stand out for being easy to use and dependable in different work settings. Their build ensures steady results without much hassle in running them.

Structural Components and Design

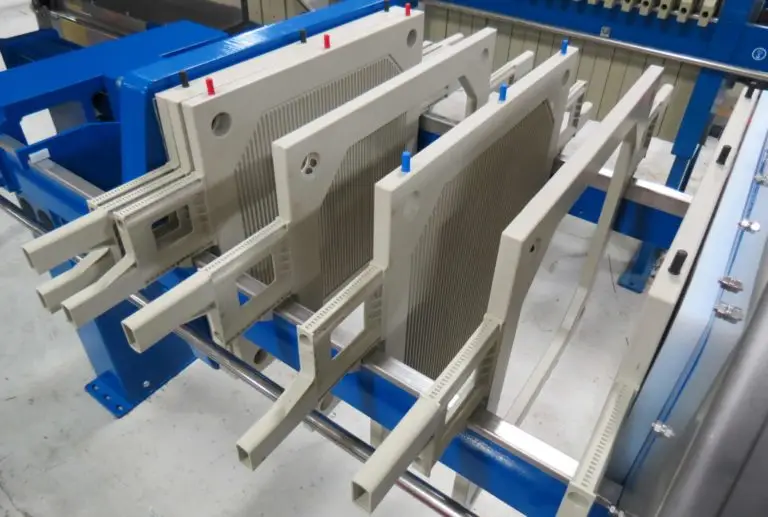

A chamber filter press has several sunken plates lined up side by side. When pressed together, they create chambers. Each plate is wrapped with a filter cloth. This cloth traps solids but lets liquid flow through.

Filtration Cycle and Process Steps

The process kicks off by pumping slurry into the chambers. As pressure rises, liquid slips through the cloth. Solids stay behind and form cakes. When the filtering is done, the plates are pulled apart. The cake is then removed by hand or with a machine.

Feeding method: Central feeding. Filter cloth: Fixed in the center. Cake discharge: Done manually. Automation: Not very automated and doesn’t adjust easily.

Advantages in Industrial Applications

Chamber filter presses cost less at the start. They’re great for jobs where some wetness in the cake is okay. These presses work well for tasks that don’t need super dry results or when money is tight.

Features and Operation of a Membrane Filter Press

Membrane filter presses boost filtering power by adding an extra pressing step after the first drying stage.

Design Characteristics and Key Components

Membrane filter presses have bendable membranes, often made of rubber or plastic. These can puff up inside each plate. After the first filtering, they squeeze the cake more to get out extra liquid.

The second step – Diaphragm squeeze: High-pressure water flows into a strong pipe. The pipe grows bigger and pushes down on the filter cake. This forces out more liquid.

Filtration Process with Squeezing Phase

First, slurry is fed in, and a cake forms, just like in chamber presses. Then, high-pressure water fills the membranes. This adds more push on the cake and cuts down wetness a lot. Extra steps like washing or air-drying can make it even better.

Air drying: Air rushes into the chamber through the feed pipe. It dries the cake fast. The sixth step – Discharge: The filter frame opens up. The cake drops into a slag bucket from both sides of the machine.

Benefits for High-Efficiency Filtration

Membrane presses leave less water in the cake, often skipping extra drying later. They also clean better when needed. With a top pressure of 16 kg, the cake gets super dry. For instance, phosphogypsum cake can have just 10% moisture, way less than the usual 25%.

Key Differences Between Chamber and Membrane Filter Presses

Though both types help split solids from liquids, their build and how well they work are quite different.

Structural and Mechanical Differences

Plate Construction Comparison

Chamber plates are basic and sunken, with no moving bits inside. On the other hand, membrane systems are tougher. Composite material filter plates go through a 1W alternating load fatigue test for each batch. This makes them last longer.

Integration of Membranes in the System

Membrane presses have inflatable parts that press the cakes after filtering. This isn’t something you find in regular chamber setups.

Performance and Efficiency Metrics

Filtration Speed and Cake Moisture Content

Membrane filters work quicker since they dry better. They cut moisture by 30-50% compared to regular ones, and 15-20% less than others. This speeds up the process, especially if drying steps need to be short.

Energy Consumption and Operational Costs

Membrane systems cost more at first because of extra parts like the diaphragm setup. But they can save energy over time. Sometimes, you can skip the usual drying process altogether, which cuts down on power use.

Suitability for Different Processing Needs

Application-Specific Recommendations

For jobs needing very low moisture or handling tiny bits, like phosphogypsum or zinc smelting, membrane filters are the best pick. A common use is in the phosphate chemical field for treating phosphogypsum. Meanwhile, chamber filters are good for basic drying tasks where keeping costs low or simplicity matters more.

Factors to Consider When Choosing Between the Two Types

A few things should help you decide between chamber and membrane options.

Nature of the Slurry or Feed Material

If the slurry is thick or has tiny particles, membrane presses work better. Their squeezing power helps dry it out under stronger pressure.

Required Moisture Content in the Final Cake

If your job needs the cake to be almost dry, like in chemical or food work, a membrane press is the way to go. It handles low moisture levels better.

Budget, Maintenance, and Operational Constraints

Chamber presses are cheaper and easier to take care of. But they might need extra steps like drying ovens afterward. Membrane setups cost more upfront. Yet, they save time per cycle, which can make up for the price over time.

Introduction to NHD as a Reliable Equipment Supplier

New Hongda, or NHD, is a well-known name that offers top-notch filtration equipment made for all sorts of industrial uses.

Overview of NHD’s Product Series Offerings

NHD has a wide range of products that cover many needs.

Filter Series & Automatic Press Filter Series

The HDLY Vertical Automatic Pressure Filter runs non-stop and gives high output.

Agitator & Thickener Series

These are built for mixing stuff before filtering in mining or chemical jobs.

Equipment for Sulfuric Acid Industry & Pressure Vessel Series

These systems are made tough for harsh settings where materials must hold up well.

Desulfurization Equipment Series & Filter Cloth Series

They offer parts for air cleaning systems and special fabrics that make filtering more accurate.

Material Series for Various Industrial Needs

From strong plastic plates to acid-proof membranes, NHD materials are picked to last long and work well in different settings.

Conclusion

Chamber filter presses give a budget-friendly way to split solids and liquids. Their simple setup works for basic needs. On the flip side, membrane filter presses step up the game with an added squeeze step. This cuts down moisture a lot, which is perfect when top efficiency or quality is a must. Choosing between them means looking at the slurry type, how dry the result needs to be, your budget, and if automation is key. NHD shines in all these areas with custom solutions and years of know-how.

FAQs:

Q1: What type of industries benefit most from using a membrane filter press?

A: Fields that need super dry results gain the most from membrane presses. Think chemical work like phosphoric acid recovery, mining tasks like phosphogypsum handling, food making, or medicine. These presses squeeze out water with high pressure, up to 16 kg, leaving very little moisture behind.

Q2: Is it possible to automate both types of filter presses?

A: Both can be set up to run on their own to some degree. But membrane presses often have more automation. They can clean themselves and have smart weighing systems. Automation: Whole-machine weighing system self-cycling operation. Chamber setups might need a person to help with unloading or cleaning unless they get extra automation add-ons.

Q3: How does NHD ensure compatibility between their equipment offerings and customer-specific materials?

A: NHD uses a 1.6m² testing machine to check how customer materials behave. This gives clear data to study. Their engineers then suggest the best setups based on real tests, not just guesses. This ensures the equipment fits well for all kinds of industrial jobs.